Hydraulic driving system for hub motor

A wheel hub motor and drive system technology, applied in auxiliary drive devices, pneumatic power devices, motor vehicles, etc., can solve the problems of poor passability of commercial trucks, achieve high safety, reduce dead weight, and easy wheel drive Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is described in detail below in conjunction with accompanying drawing:

[0024] The purpose of the patent of this invention is to provide a wheel hub motor hydraulic drive system installed on the front wheel (non-drive wheel), so as to overcome the shortcomings of poor passability of commercial trucks on bad roads, improve the performance of the car, and improve its fuel economy sex.

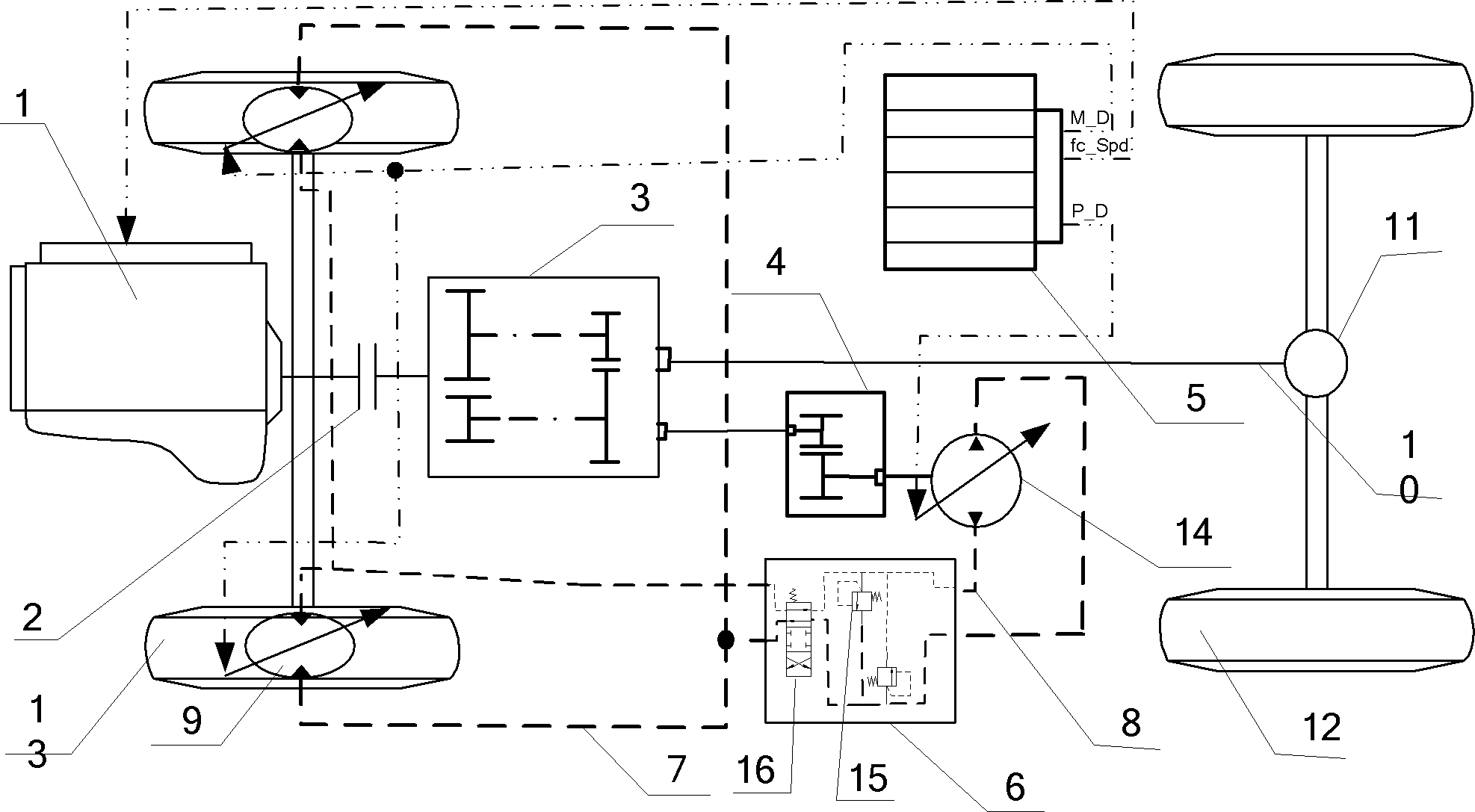

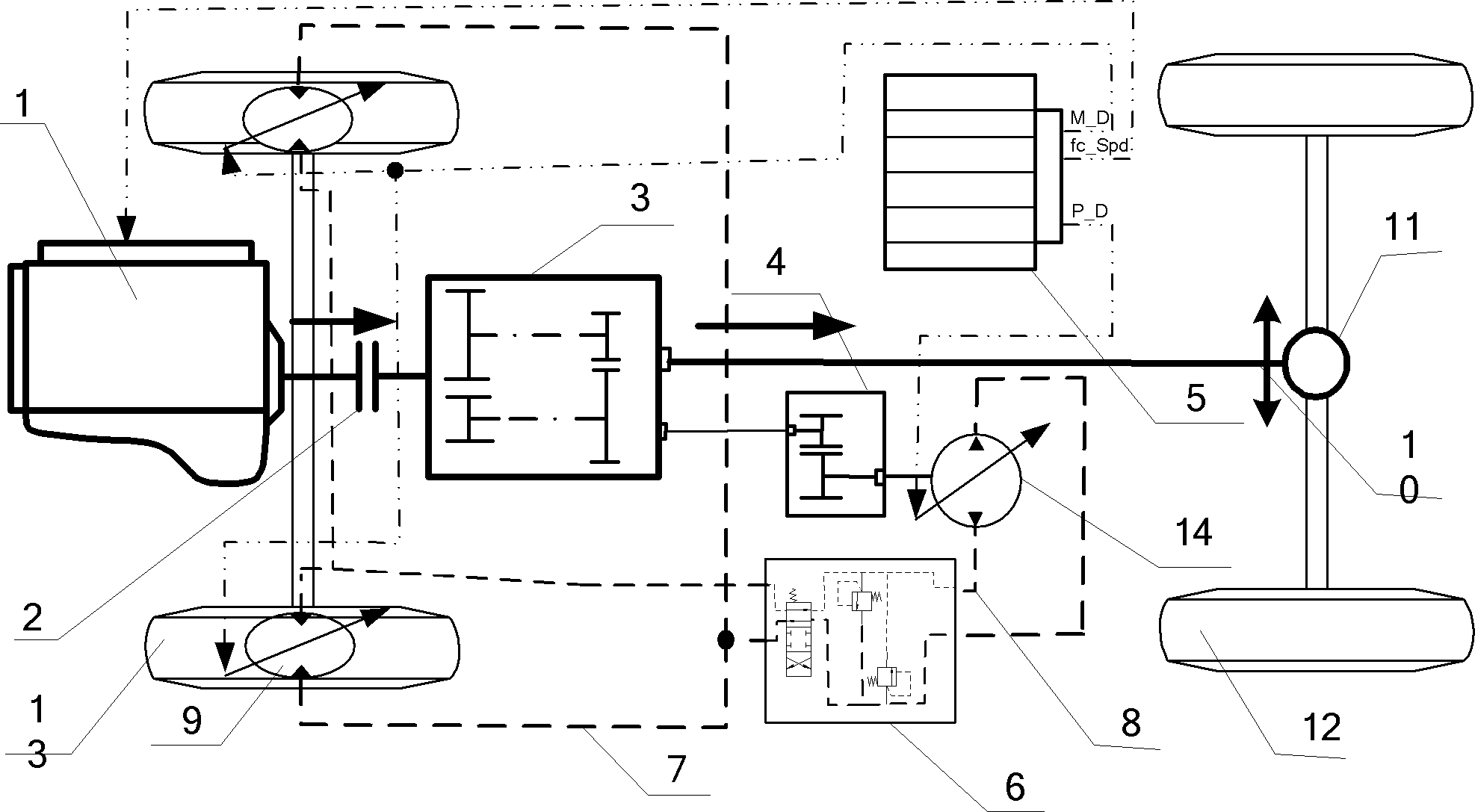

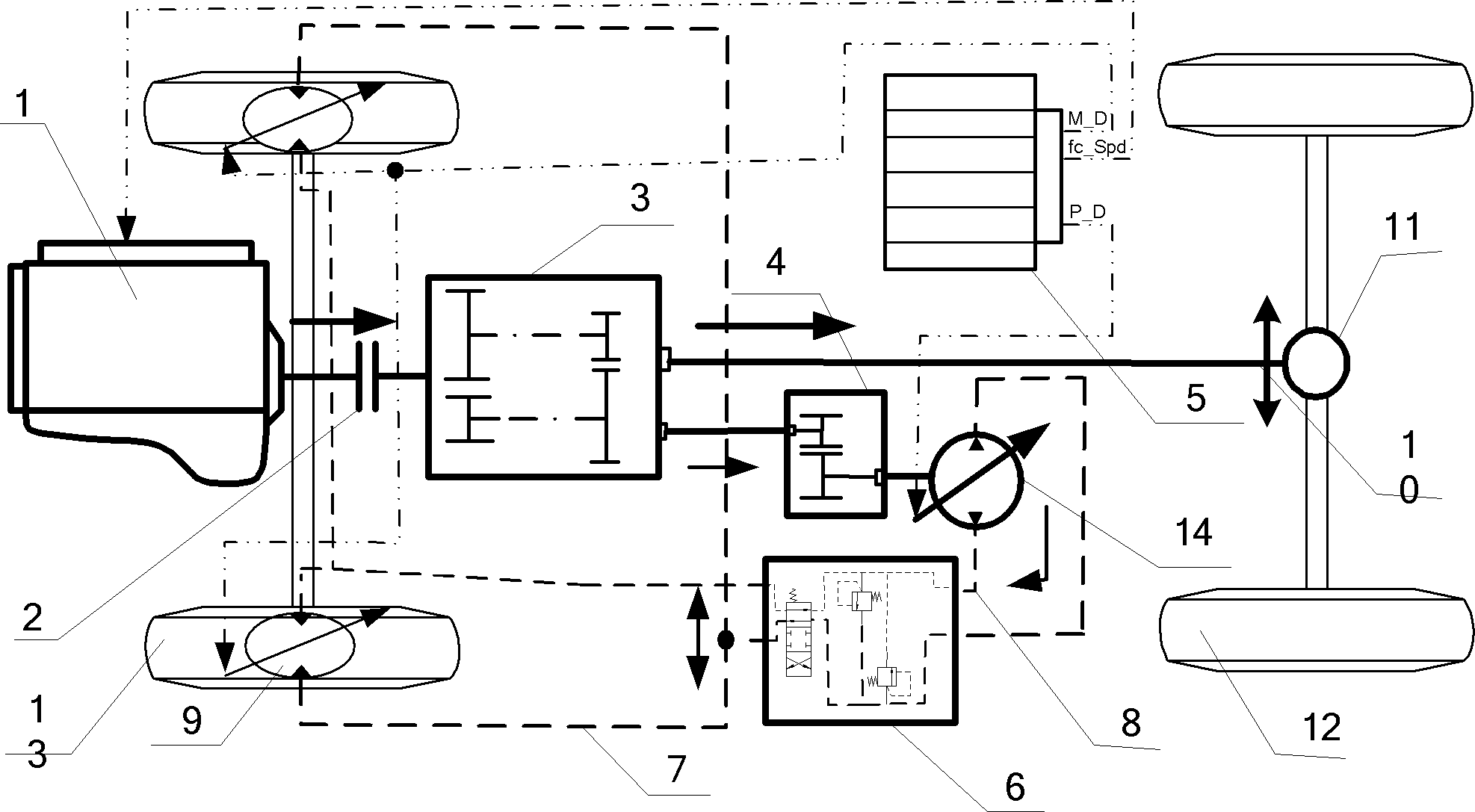

[0025] refer to figure 1 , the hub motor hydraulic drive system includes (engine 1, clutch 2, gearbox 3), power take-off 4, variable pump 14, hydraulic control valve group 6, and two radial piston variable hubs with the same structure hydraulic motor9.

[0026] The power take-off 4 includes a housing, an input shaft, an output shaft, an input shaft gear, an output shaft gear and two pairs of rolling bearings.

[0027] The input shaft and the output shaft are installed on the casing through rolling bearings and are in the same horizontal plane, and the rotation ax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com