Thermal system and technology for producing float zone doped single crystal silicon having size phi of 6 inches

A silicon single crystal, thermal system technology, applied in the direction of single crystal growth, single crystal growth, self-area melting method, etc., can solve the problem of increasing the risk of bud breaking, and achieve the effect of meeting the needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

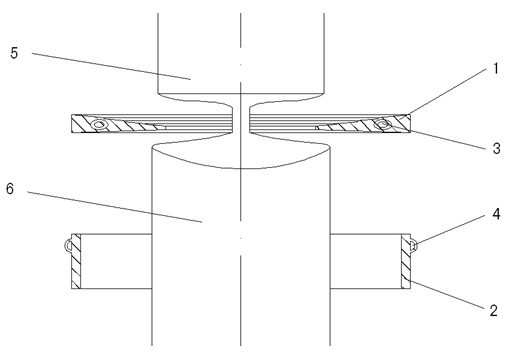

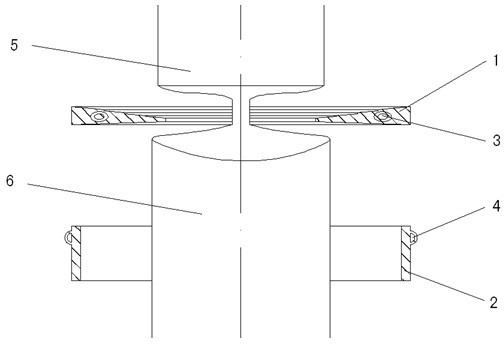

[0019] The present invention will be further described below in conjunction with embodiment and accompanying drawing. refer to figure 1 , a thermal system for producing molten gas-doped silicon single crystals in a Φ6-inch area includes a coil 1 and an insulating cylinder 2. The upper surface of the coil 1 is an inclined multi-step coil. The outer diameter of the coil 1 is Φ300mm, the inner diameter is Φ50mm, and the thickness is 30mm. The heat preservation tube 2 has a diameter of Φ300mm and a height of 100mm. The distance between the coil 1 and the insulation cylinder 2 is 100mm. The cooling water channel 3 of the coil 1 and the cooling water channel 4 of the insulation cylinder 2 are respectively located inside the two.

[0020] The equipment used to produce Φ6-inch molten gas-doped silicon single crystal is PVA FZ-30 type, and the specific steps of the process are as follows:

[0021] 1. First open the furnace door, wipe the inner wall of the furnace door, the upper fur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com