Device and method for testing wind pressure on surface of building structure

A technology for testing devices and building structures, applied in the testing of machines/structural components, measuring devices, aerodynamic tests, etc., can solve problems such as distortion, and achieve the effects of light weight, good portability, and high testing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1: with reference to accompanying drawing:

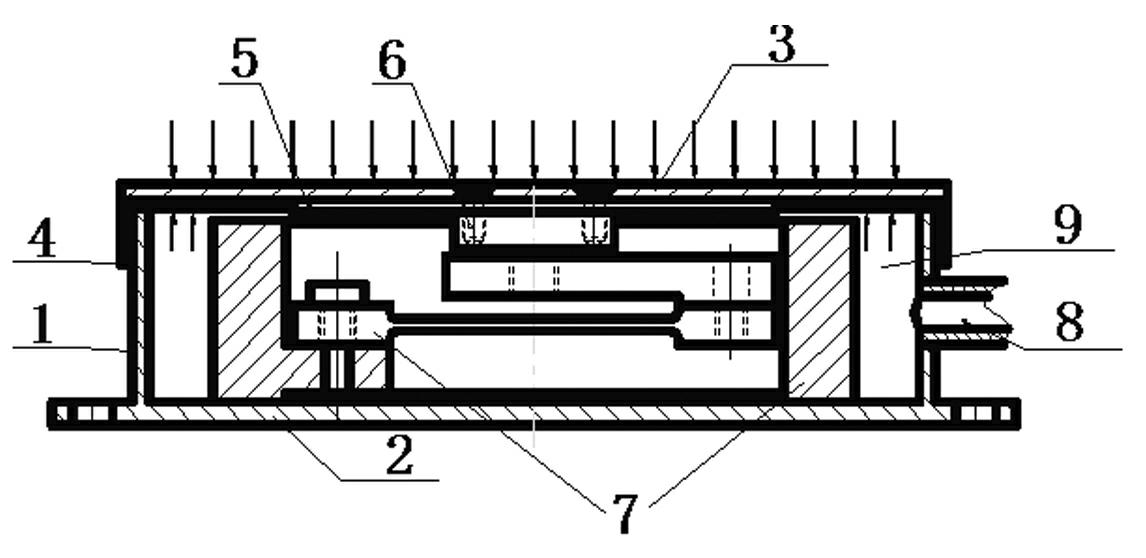

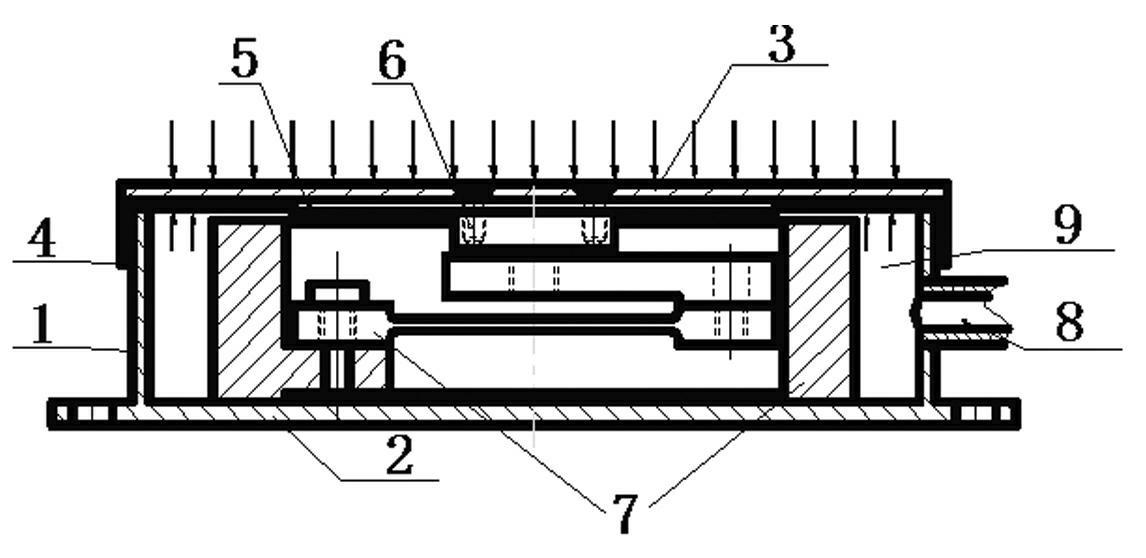

[0018] In this embodiment, a cylindrical shell with a diameter of 100 mm and a height of 26 mm is provided, and its lower part and a chassis 2 with a diameter of 120 mm and a thickness of 2 to 3 mm are machined to form a thin-walled cavity cylinder 1 . The upper part of the cavity cylinder body 1 is provided with a disc-shaped load-bearing panel 3 with a diameter of 100 mm and a thickness of 2 mm, and the lower end of the disc-shaped load-bearing panel 3 covers the cavity cylinder body through a sealing structure 4; they together form a Thin wall cavity box. A miniature force sensor 7 with a height of 20mm-25mm and a beam structure is arranged in the thin-walled cavity box. The upper part of the miniature force sensor 7 is connected with the balance disc 5 , and the lower part is fixedly connected with the chassis 2 . A hole tube 8 with a diameter of 6mm is provided on the side of the thin-walled cavity box. The ...

Embodiment 2

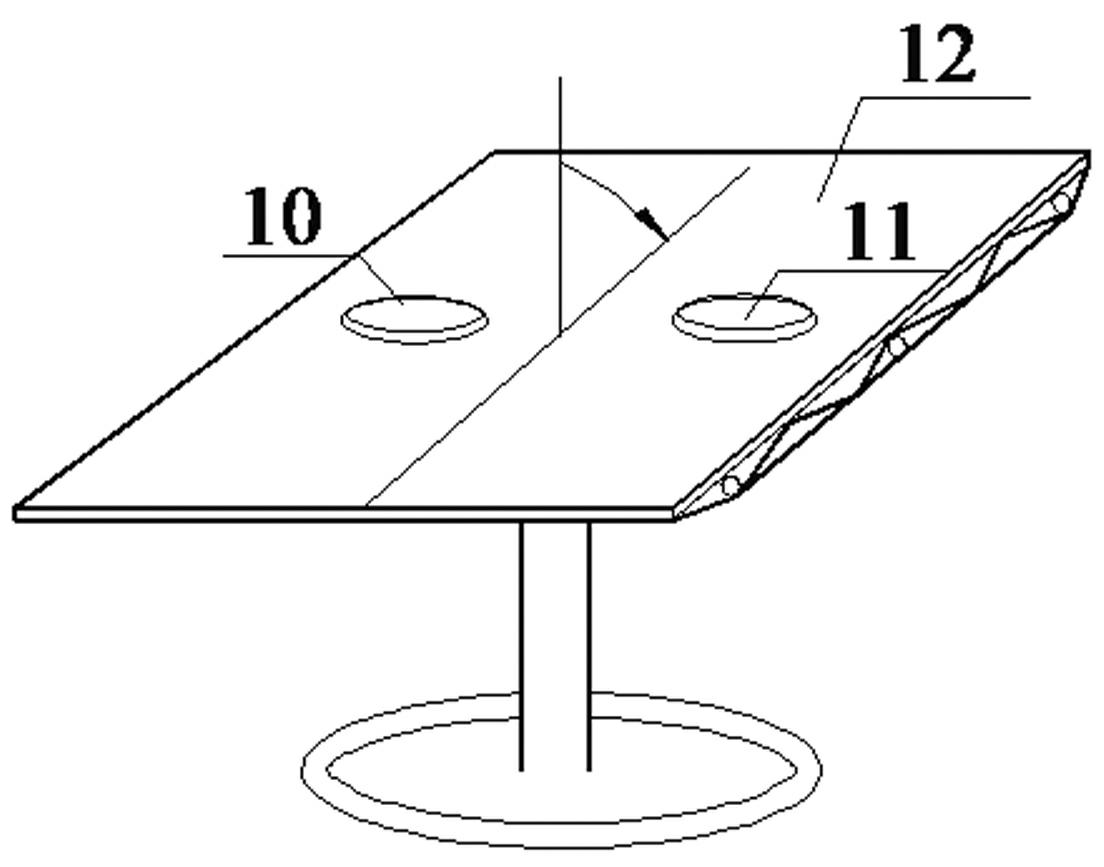

[0022] (1) Calibrate the test accuracy of the wind pressure test device; according to the wind tunnel pressure test of the 1:1 rigid model in the prior art, it is determined that the wind pressure test device tests the wind pressure and the incoming wind speed pressure under different elevation angle conditions corresponding relationship. In the wind tunnel test, first design a flat support 12 that can rotate freely in the vertical direction, and its elevation angle can vary from 0 to 90 degrees when rotating; on the flat support 12, a wind pressure test device 10 and a rigidity of 1:1 are symmetrically arranged. Model 11, the pressure measuring points of the shown rigid model 11 are arranged at an angle of 15 degrees and in 8 equal parts along the diameter direction. According to the results of the wind tunnel pressure test, the test accuracy of the wind pressure test device is calibrated, and the corresponding relationship between the wind pressure tested by the wind pressur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com