Method for improving small-spherical defect in manufacture process of shallow trench isolation substrate

A shallow trench and isolation liner technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of yield loss, thin film deposition and removal, etc., and achieve the effect of yield improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

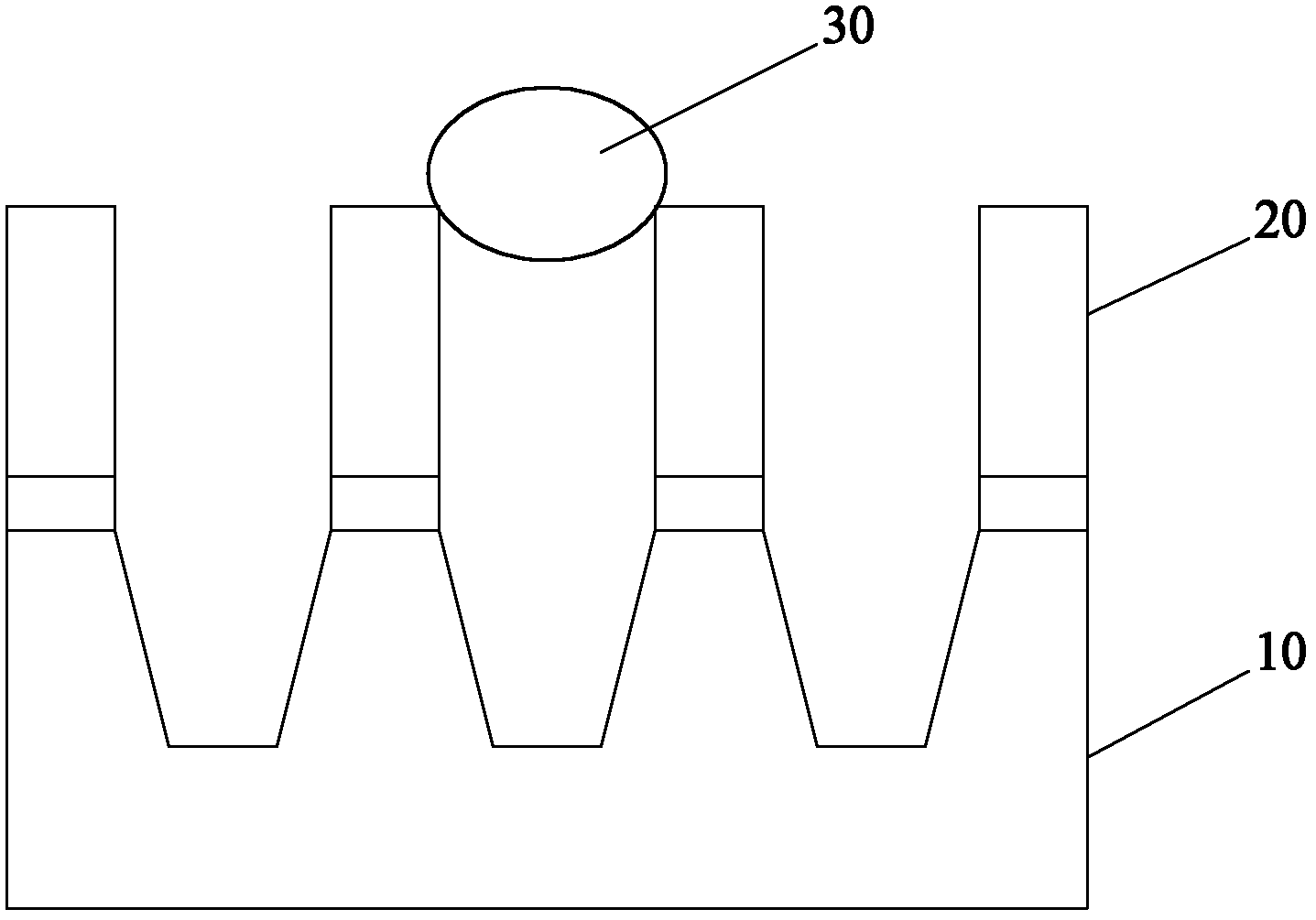

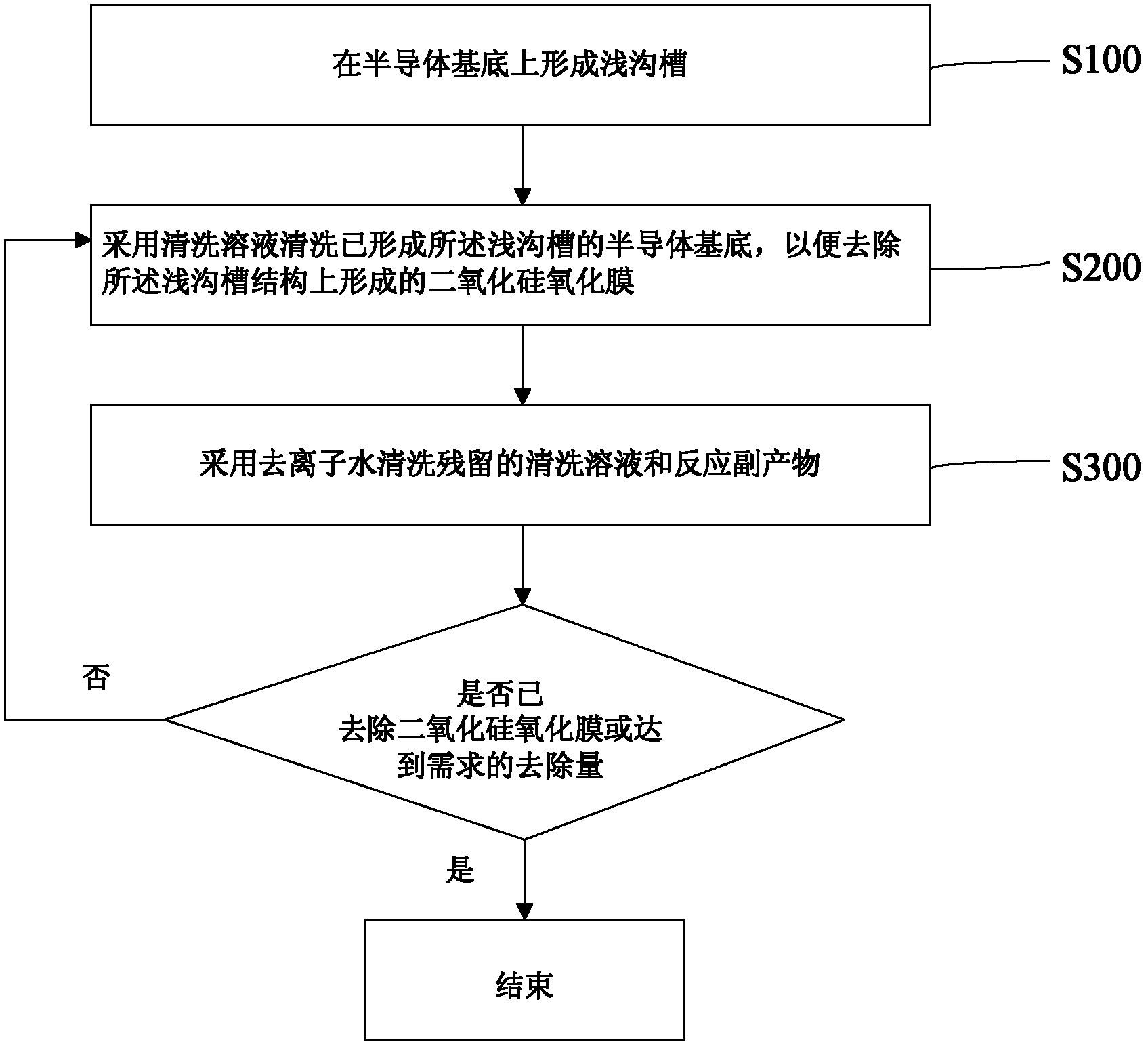

[0019] Please refer to figure 2 , figure 2 Shown is a flowchart of a method for improving small spherical defects in shallow trench isolation substrate manufacturing processes according to a preferred embodiment of the present invention.

[0020] The present invention proposes a method for improving small spherical defects in the shallow trench isolation substrate manufacturing process, which includes the following steps:

[0021] Step S100: forming shallow trenches on the semiconductor substrate;

[0022] Step S200: using a cleaning solution to clean the semiconductor substrate on which the shallow trench has been formed, so as to remove the silicon dioxide oxide film formed on the shallow trench structure;

[0023] Step S300: cleaning the residual cleaning solution and reaction by-products with deionized water;

[0024] Repeat the above cleaning steps until the silicon dioxide oxide film is removed or the required removal amount is reached,

[0025] Wherein the cleanin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com