Clamp and method for cutting and welding radiator

A cutting and welding technology for radiators, applied in the field of radiator cutting and welding fixtures, can solve the problems of large comprehensive error of radiator products, low interchangeability of heat exchangers, and inconsistent positioning benchmarks, so as to reduce labor intensity and avoid The effect of synthesizing errors and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

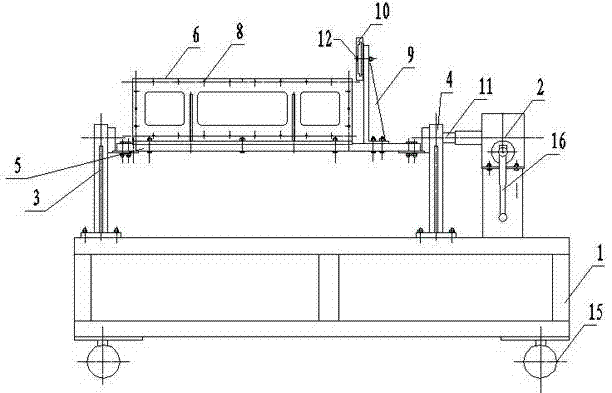

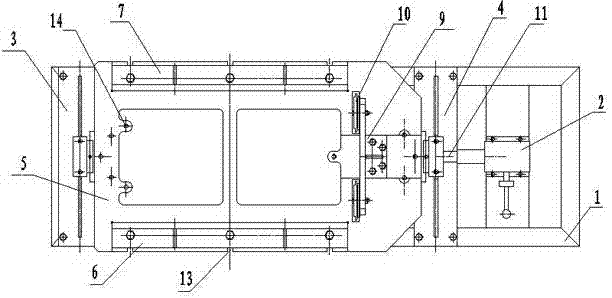

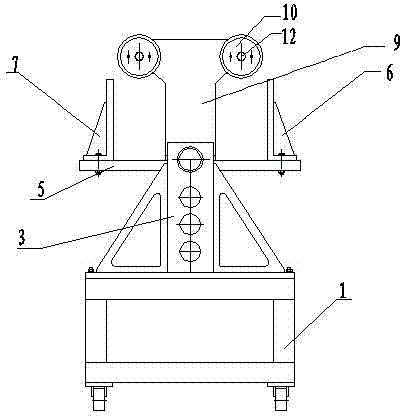

[0031] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

[0032] As shown in the figure, a radiator cutting and welding jig includes a base 1, a support frame on the base and a reducer 2, and the support frame includes a left support frame 3 and a right support frame 4. A rotatable base plate 5 is provided between the support frames, and there is a gap between the base plate and the base to prevent the base plate from colliding with the base when it rotates. plate 7, the front bracket plate and the rear bracket plate are provided with positioning holes 8 corresponding to the positions of the threaded holes on the flange of the cold air flow channel of the radiator and having the same size, and the right end of the bottom plate is provided with a support assembly 9, so The support assembly is provided with a positioning block 10, and the positioning block is provided with a fixing part for fixing the hot a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com