Engineering machinery rotation brush performance test apparatus and method thereof

A technology of rotating brushes and test devices, applied in the directions of measuring devices, measuring electricity, measuring electrical variables, etc., can solve the problems that the durability performance of rotating brushes, the performance of contact voltage drop cannot be measured, the electrical control system of the host cannot work normally, Affect work efficiency and maintenance costs, and achieve the effect of high degree of automation, strong practicability, and reliable work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings.

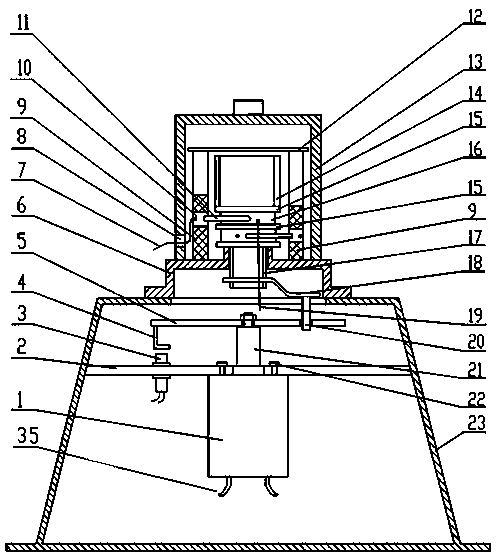

[0037] like figure 1 As shown, what is installed on the upper part of the test device bracket 23 is the experimental object of the present invention—the rotating brush, which includes the brush support 6, the rotating drum 17 installed in the center of the brush support 6, and the rotating slip ring of the rotating drum 17. The stack 14, the insulating ring 15 installed between the adjacent rotating slip rings 16, the insulating block 9 installed on the brush support 6, the elastic brush 11 connected to the insulating block 9 through the brush connecting seat 10, the top of the insulating block 9 The installed brushes are connected to the base plate 12 and the brush cover 13 that covers the outside of the insulating block 9 .

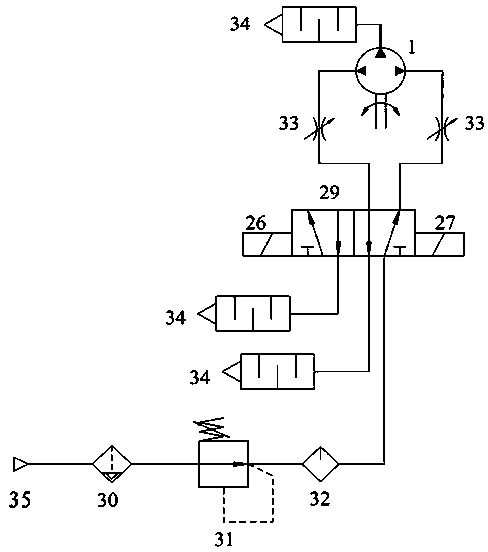

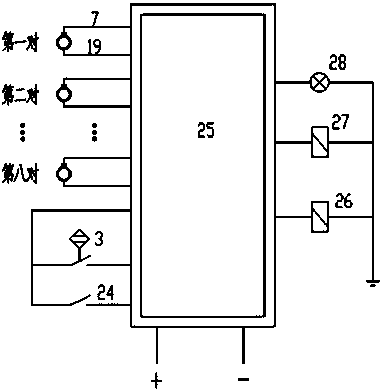

[0038] The performance testing device of the construction machinery rotating brush in the present invention includes a mechanical system, a pn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com