Seawater coagulation turbidity removing system

A technology of seawater and coagulation, which is applied in the direction of sedimentation tanks, feeding/discharging devices of sedimentation tanks, chemical instruments and methods, etc. It can solve the problem that the quality of effluent water cannot meet the production process, the dosage is inaccurate, and it is difficult to control in real time, etc. problem, to achieve the effect of precise control of dosing amount, guarantee of effluent quality, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

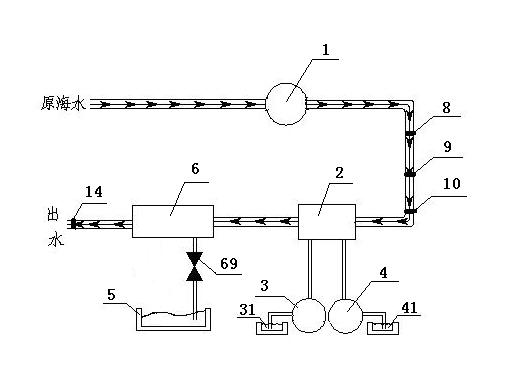

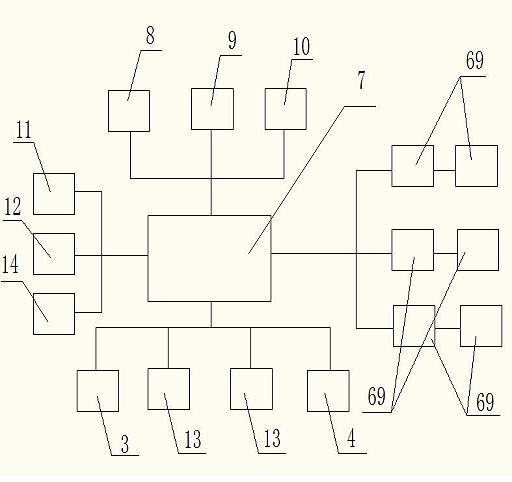

[0037] like figure 1 A seawater coagulation and turbidity removal system shown includes a raw water pump 1 connected to raw seawater, a pipeline mixer 2, a flocculant dosing pump 3, a coagulant aid dosing pump 4, a sludge discharge tank 5, and a coagulation and sedimentation pump. The device 6 and the PLC controller 7, the raw water pump 1, the pipeline mixer 2 and the coagulation and sedimentation device 6 are connected through pipelines in turn, and the output port of the flocculant dosing pump 3 and the output port of the coagulant dosing pump 4 are respectively passed through The pipeline is connected to the dosing port of the pipeline mixer 2, and the input port of the flocculant dosing pump 3 and the input port of the coagulant dosing pump 4 are respectively connected to the flocculant (ferric chloride) filled flocculant through the pipeline. Agent pool 31 and coagulant aid pool 41 equipped with coagulant (polyacrylamide), flocculant dosing pump 3 and coagulant dosing pu...

Embodiment 2

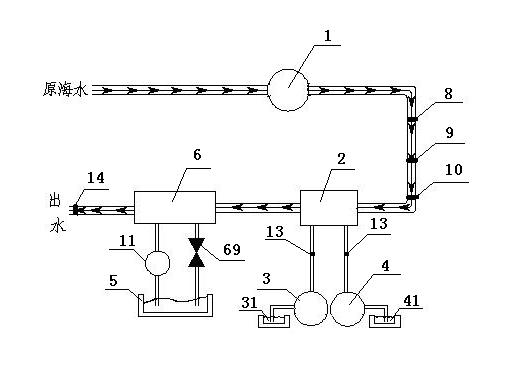

[0041] The difference between this embodiment and embodiment 1 is that a mud circulation pump 11 is also provided between the coagulation sedimentation device 6 and the mud discharge tank 5 (such as figure 2 shown), the output port of the mud circulation pump 11 is connected to the water inlet 65 of the coagulation and sedimentation device through a pipeline, and the input port of the mud circulation pump 11 is connected to the mud discharge tank 5 through a pipeline, and the mud discharge tank 5 is equipped with a liquid level The sensor 12 and the liquid level sensor 12 are connected with the PLC controller 7 . The flocculant dosing pump 3 and the coagulant dosing pump 4 are all pumps without metering function. 2 are provided with a flow sensor 13 on the connecting pipeline, the flow sensor 13 is connected with the PLC controller 7, the flocculant is a mixture of ferric chloride and composite polyferric, and the coagulation aid is a mixture of polyacrylamide and bone glue. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com