Electric table type grinding machine

A grinding machine and electric technology, applied in the field of grinding machines, can solve the problems of affecting the grinding effect, easily hurting hands, and being easily touched by hard objects, etc., and achieve the effect of good grinding effect, convenient use and safe storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

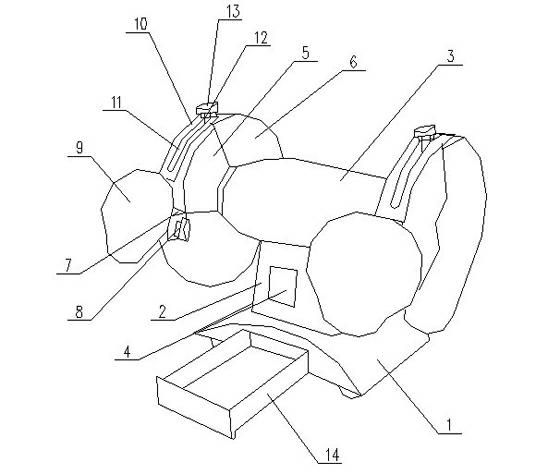

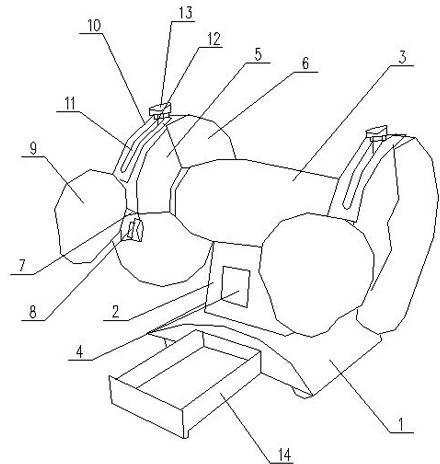

[0009] Such as figure 1 As shown, the desktop electric grinder includes: a base 1, a switch panel 2 arranged on the base 1, a fuselage power source 3 arranged on the upper end of the switch panel 2, and a fuselage power source 3 arranged on the switch panel 2 for controlling the fuselage power source 3 The switch 4 is respectively arranged on the two ends of the fuselage power source 3 and the grinding wheel sheet 5 driven by the fuselage power source 3 and the grinding wheel sheet protective cover 6 arranged on the outside of the grinding wheel sheet 5, on which the grinding wheel sheet 5 grinds the working surface Below is provided with workbench 7, and described workbench 7 is fixed on the emery wheel sheet protective cover 6 by screw 8; Above described emery wheel sheet 5 grinding working surface, be provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com