Method for preparing reproduced cheese and obtained reproduced cheese thereof

A technology for processed cheese and natural cheese, which is applied in cheese substitutes, dairy products, applications, etc., can solve the problems of time-consuming, labor-intensive, and complicated processes, and achieve the effect of simple operation, simple preparation method, and strong milk flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Raw materials: 83% cheddar cheese matured for three months, 0.7% sodium citrate, 0.35% sodium hexametaphosphate, 0.15% sodium pyrophosphate, 0.3% sodium phosphate, 15.5% water; percentages are mass percentages.

[0044] Preparation:

[0045] ①According to the above formula, put the chopped 0.5cm~2cm natural cheese and other raw materials into the melting pot, without heating, stir with a blunt knife with a blade thickness of 2mm at 1000rpm for 3min to obtain a premixed slurry;

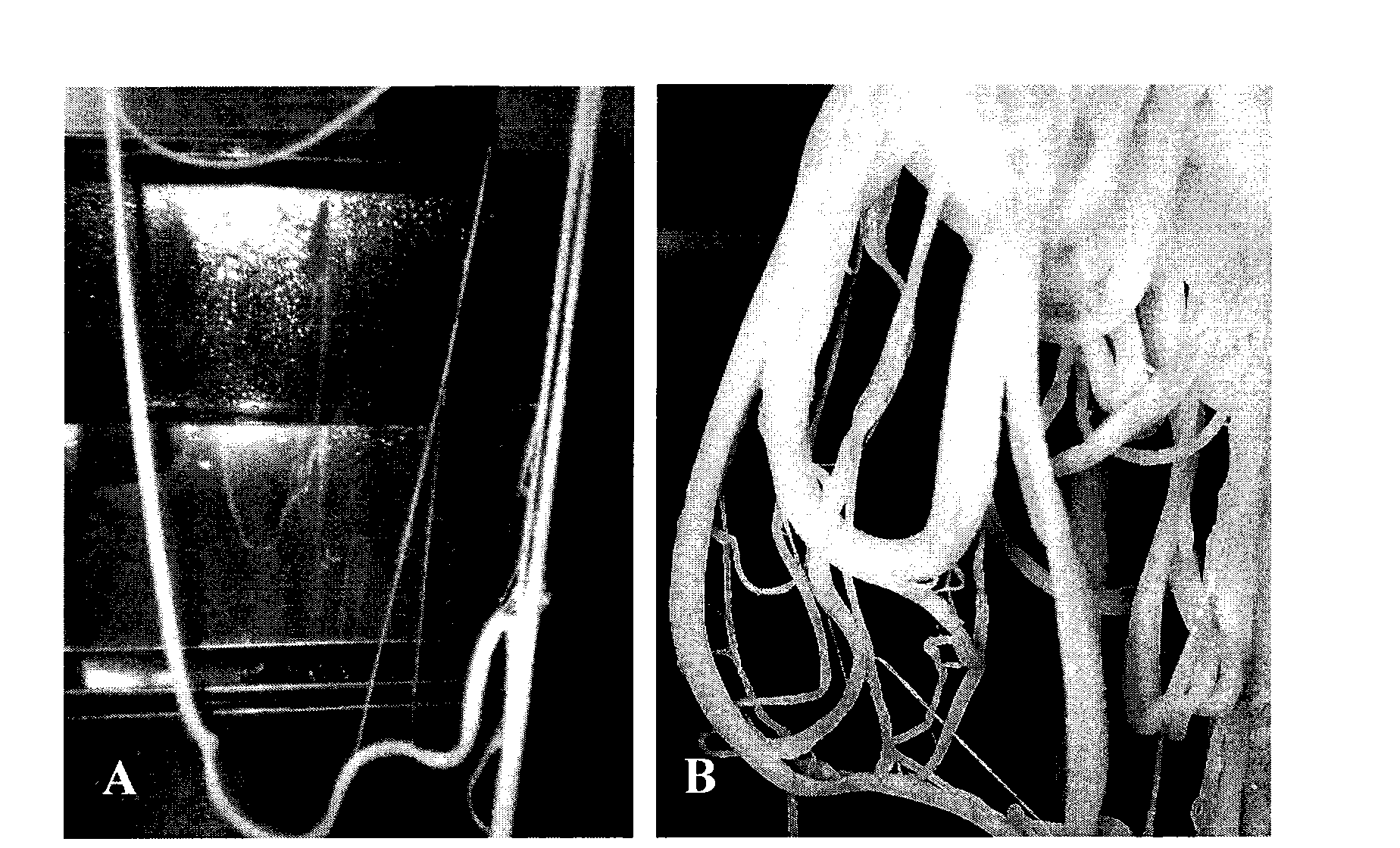

[0046] ② Stir the pre-mixed slurry at a speed of 1000rpm, heat the steam directly to a temperature of 80°C, and then keep it warm for 6 minutes until the wire drawing appears;

[0047] ③Extruded to obtain cheese sticks with a diameter of 1.8cm×length of 10cm;

[0048] ④ Afterwards, hot fill aseptic packaging, cool down, and refrigerate.

[0049] After testing, the indexes of the processed cheese obtained are: fat content 22%; dry matter 53%; pH 5.2.

Embodiment 2

[0051] Ingredients: 75% one-month mature cheddar cheese, 5% rennet casein, 0.7% sodium citrate, 0.35% sodium hexametaphosphate, 0.15% sodium pyrophosphate, 0.3% sodium phosphate, 18.5% water; percentages are mass percentage.

[0052] Preparation:

[0053] ①According to the above formula, put the chopped 0.5cm~2cm natural cheese and other raw materials into the melting pot, without heating, stir with a blunt knife with a blade thickness of 10mm at 2000rpm for 1min to obtain a premixed slurry;

[0054] ② Stir the pre-mixed slurry at a speed of 2000rpm, heat the steam directly to a temperature of 75°C, and then keep it warm for 2 minutes until the wire drawing appears;

[0055] ③Extruded to obtain cheese sticks with a diameter of 1.8cm×length of 10cm;

[0056] ④ Afterwards, hot fill aseptic packaging, cool down, and refrigerate.

[0057] After testing, the indexes of the processed cheese obtained are: fat content 28%; dry matter 55%; pH 5.5.

Embodiment 3

[0059] Ingredients: 22% one-month mature Gouda cheese, 22% one-month mature cheddar cheese, 9% rennet, 12% palm oil, 1% sodium citrate, 0.5% sodium hexametaphosphate, 0.20% sodium pyrophosphate , 1% salt, 0.75% citric acid, 0.05% cheese essence, 31.5% water; percentages are mass percentages.

[0060] Preparation:

[0061] ①According to the above formula, put the chopped 0.5cm~2cm natural cheese and other raw materials into the melting pot, without heating, stir with a blunt knife with a blade thickness of 5mm at 2000rpm for 1min to obtain a premixed slurry;

[0062] ② Stir the pre-mixed slurry at a speed of 1500rpm, heat the steam directly to a temperature of 80°C, and then keep it warm for 4 minutes until the wire drawing appears;

[0063] ③Extruded to obtain cheese sticks with a diameter of 1.8cm×length of 10cm;

[0064] ④ Afterwards, hot fill aseptic packaging, cool down, and refrigerate.

[0065] After testing, the indexes of the processed cheese obtained are: fat conte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com