Rice straw ensilage method

A technology of rice straw and silage is applied in the preservation method, application, animal feed and other directions of animal feed raw materials, which can solve the problems of poor palatability, high crude fiber content, and low crude protein content of rice straw, and achieves lower pH value and simple operation. , the effect of increasing lactic acid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will now be further illustrated by preferred embodiments.

[0013] A rice straw silage method has the following steps:

[0014] (1), the freshly harvested green and yellow rice stalks are cut into 10cm segments;

[0015] (2), the cut rice straws are piled up in the silage cellar, compacted every 100 cubic meters, and spray 150Kg of silage lactic acid bacteria starter at the same time, after spraying, continue to pile up the rice straw and continue to spray the silage lactic acid bacteria starter until the The silo is full;

[0016] (3) After the silage is completed, spread a plastic film around the silage pile for sealing, and at the same time compact the silage straw, and press sandbags after the silage is sealed as a whole.

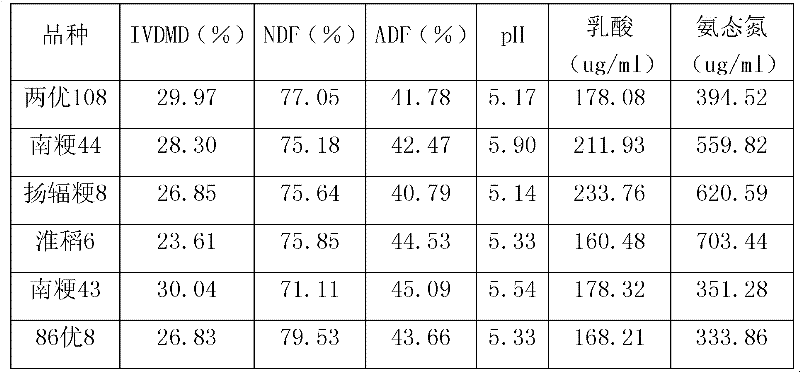

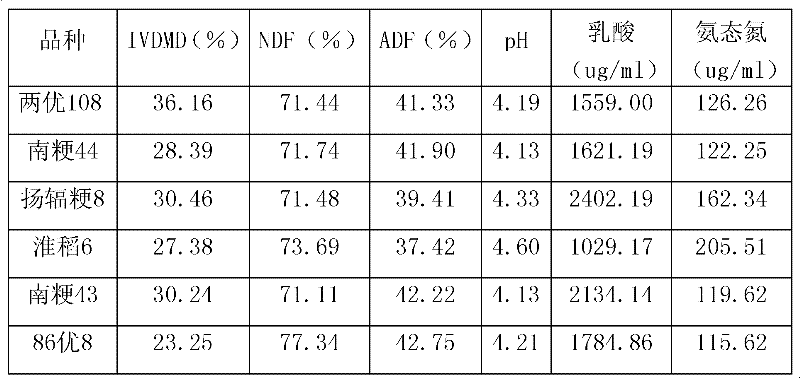

[0017] The quality analysis of rice straw obtained by experimental detection without adding silage lactic acid bacteria starter and adding silage lactic acid bacteria starter, the steps are as follows:

[0018] (1), 6 ric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com