Probiotic gel and preparation method thereof

A technology of probiotics and gel, which is applied in the preparation of the gel and in the field of probiotic gel, can solve the problems of side effects and no biologically active substances added, and achieve the goal of increasing health care functions, increasing interest, and improving nutritional value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

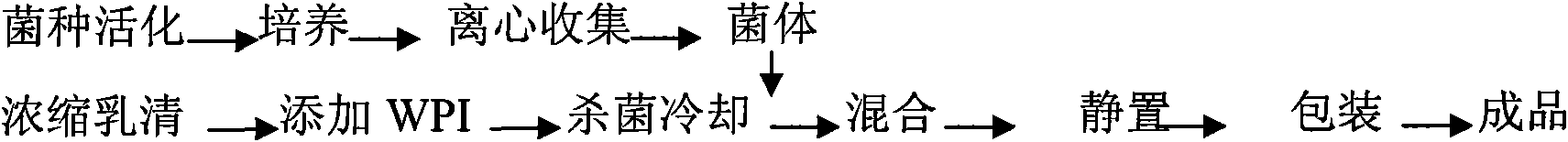

Method used

Image

Examples

Embodiment 1

[0022] The preparation of embodiment 1 lactic acid bacteria gel

[0023] This example takes Lactobacillus acidophilus as an example to illustrate the preparation method of the gel of the present invention

[0024] 1. Strain: Culture Lactobacillus acidophilus CGMCC 1084 (China Microbial Culture Collection Management Committee) in MRS medium at 37°C for 24 hours, collect the bacteria by centrifugation, and set aside;

[0025] 2. Gel base material: use whey concentrate as the base material (whey protein content is 3%), add appropriate amount of WPI until the whey protein content is 12%, heat at 80°C for 20min, cool to 45°C, and set aside;

[0026] 3. Mixing: Mix the centrifuged bacteria and the gel base material in a certain proportion until the bacteria concentration reaches 1.5×10 11 cfu / ml, spare;

[0027] 4. Standing and refrigerating: Mix the mixed bacteria with the gel base material, and let stand at 6°C to form a gel. The number of live bacteria in the obtained probioti...

Embodiment 2

[0029] The preparation of embodiment 2 lactic acid bacteria gel

[0030] 1. Strains: Culture Lactobacillus rhamnosus in MRS medium at 37°C for 24 hours, collect the bacteria by centrifugation, and set aside;

[0031] 2. Gel base material: take whey concentrate as the base material (whey protein content is 7%), add appropriate amount of WPI until the whey protein content is 16%, heat at 95°C for 10min, cool to 55°C, and set aside;

[0032] 3. Mixing: Mix the centrifuged bacteria with the gel base material in a certain proportion until the bacteria concentration is 1.0×10 9 cfu / ml, spare;

[0033] 4. Standing and refrigerating: Mix the mixed bacteria with the gel base material, and stand at 10°C to form a gel. The number of live bacteria in the obtained microcapsules can reach 10 8 cfu / ml.

[0034] The obtained lactic acid bacteria microcapsule gel was stored at 4°C for 9 months, and the number of viable bacteria could still reach 10. 8 cfu / ml.

Embodiment 3

[0035] The preparation of embodiment 3 lactic acid bacteria gel

[0036] 1. Strains: Culture Lactobacillus paracasei in MRS medium at 37°C for 24 hours, collect the bacteria by centrifugation, and set aside;

[0037] 2. Gel base material: use whey concentrate as the base material (whey protein content is 5%), add an appropriate amount of WPI until the whey protein content is 8%, heat at 65°C for 30min, cool to 35°C, and set aside;

[0038] 3. Mixing: Mix the centrifuged bacteria and the gel base material in a certain proportion until the bacteria concentration is 1.5×10 10 cfu / ml, spare;

[0039] 4. Standing and refrigerating: Mix the mixed bacteria with the gel base material, and let stand at 2°C to form a gel. The number of live bacteria in the obtained microcapsules can reach 10 10 cfu / ml.

[0040] The obtained lactic acid bacteria microcapsule gel was stored at 4°C for 9 months, and the number of viable bacteria could still reach 10. 10 cfu / ml.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viable count | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com