Device and method for removing electronic devices/components and soldered tin from waste circuit boards

A technology for electronic components and waste circuit boards, applied in auxiliary devices, welding equipment, metal processing and other directions, can solve the problems of volatilization of toxic elements, high energy consumption, and low heat utilization rate in circuit boards, and reduce labor intensity. , The effect of ensuring air quality and accelerating air circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

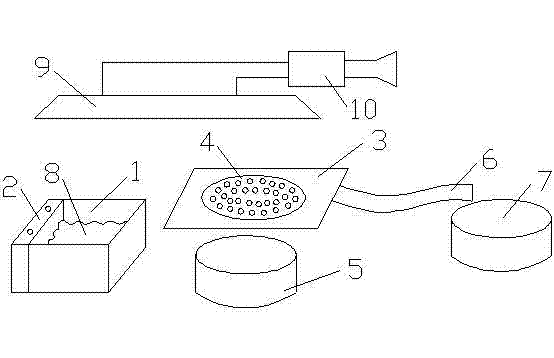

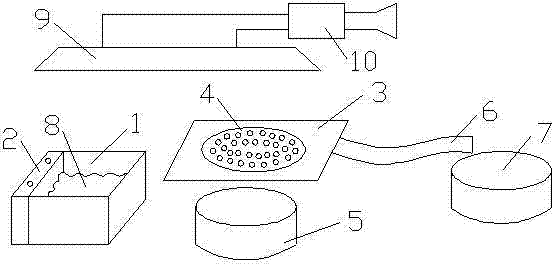

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

[0022] Such as figure 1 As shown, a device for removing electronic components and solder of waste circuit boards includes a component collection box 5, a circuit board collection box 7 and a vibrating component removal platform 3, and also includes a tin melting furnace 1. The tin melting furnace 1 includes a temperature control platform 2, and solder 8 is placed in the tin melting furnace 1. An air extraction device 9 and a gas adsorption purification device 10 connected to the air extraction device 9 are installed above the tin melting furnace 1 and the component removal platform 3 . A screen 4 is arranged on the component removal platform 3 , the component collection box 5 is located below the screen 4 , and a conveyor belt 6 is installed between the component removal platform 3 and the circuit board collector 7 .

[0023] The method for removing electronic compon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com