Tire removing apparatus for realization of on-line weighing measurement and method used by same

A technology of weighing and measuring circuits, which is applied in the field of rubber machinery, can solve the problems of heavy labor load of operators, prolonging the production cycle, and unfavorable production automation level, so as to reduce manual intervention and labor load, reduce process links, and improve the overall quality of tires. The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

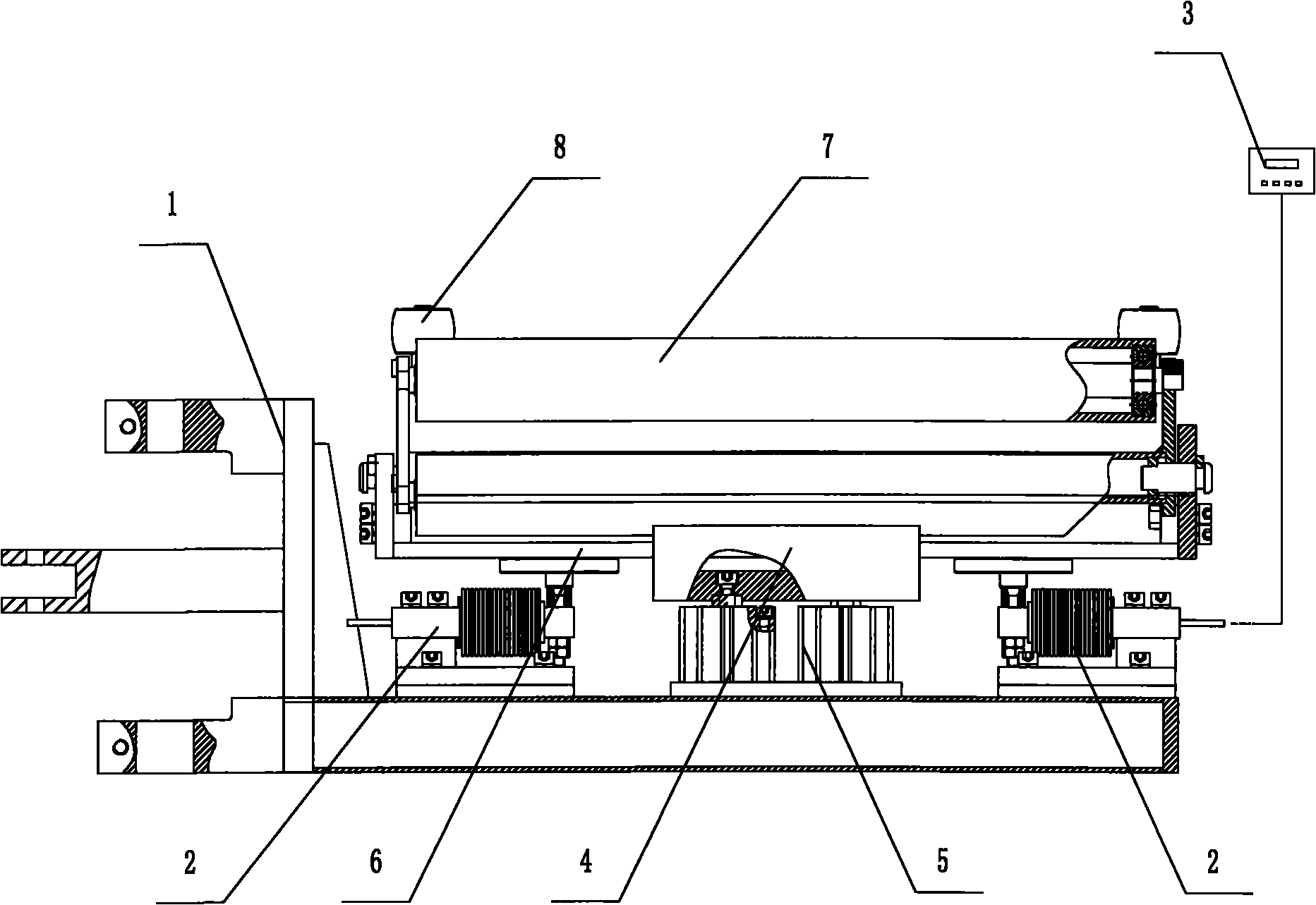

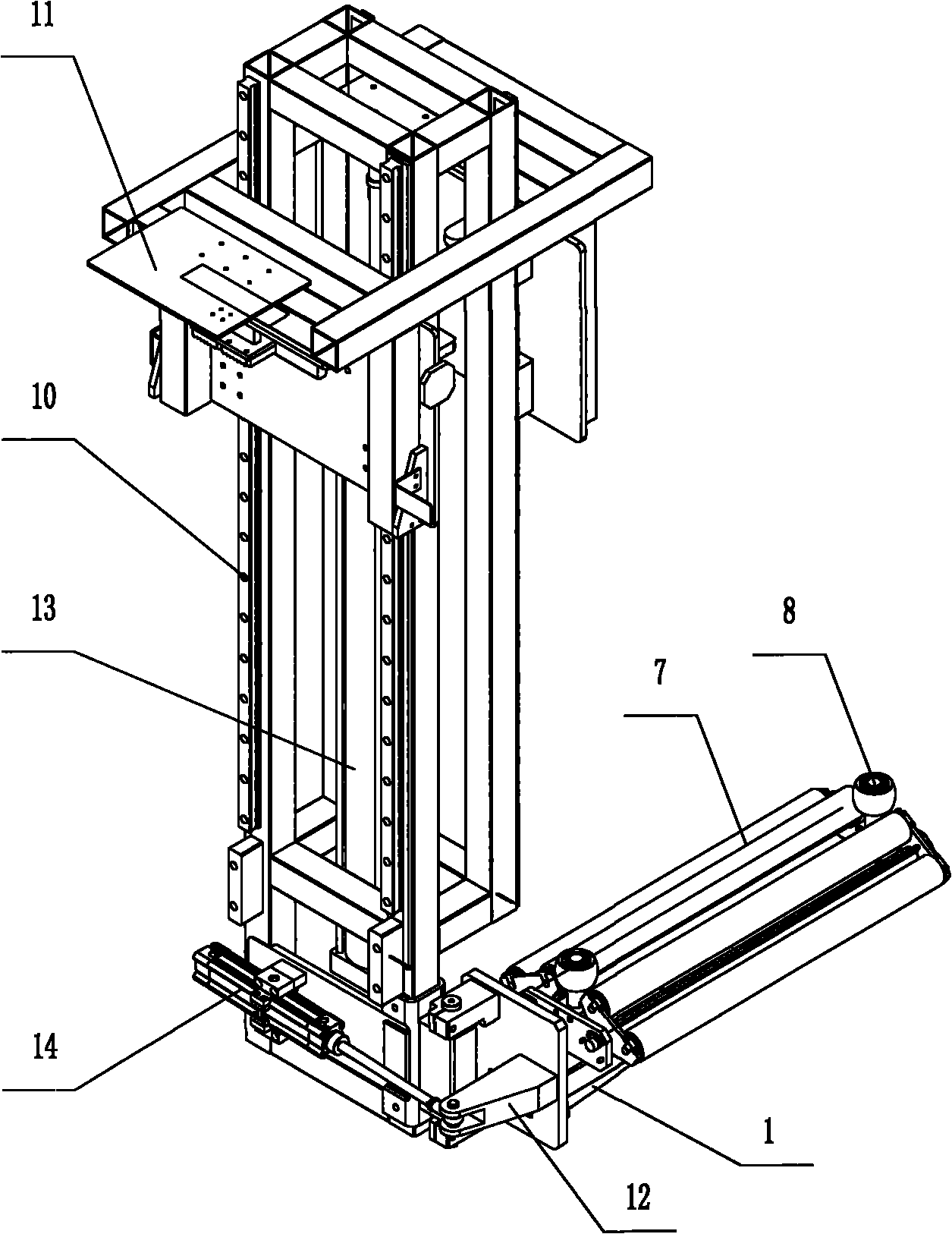

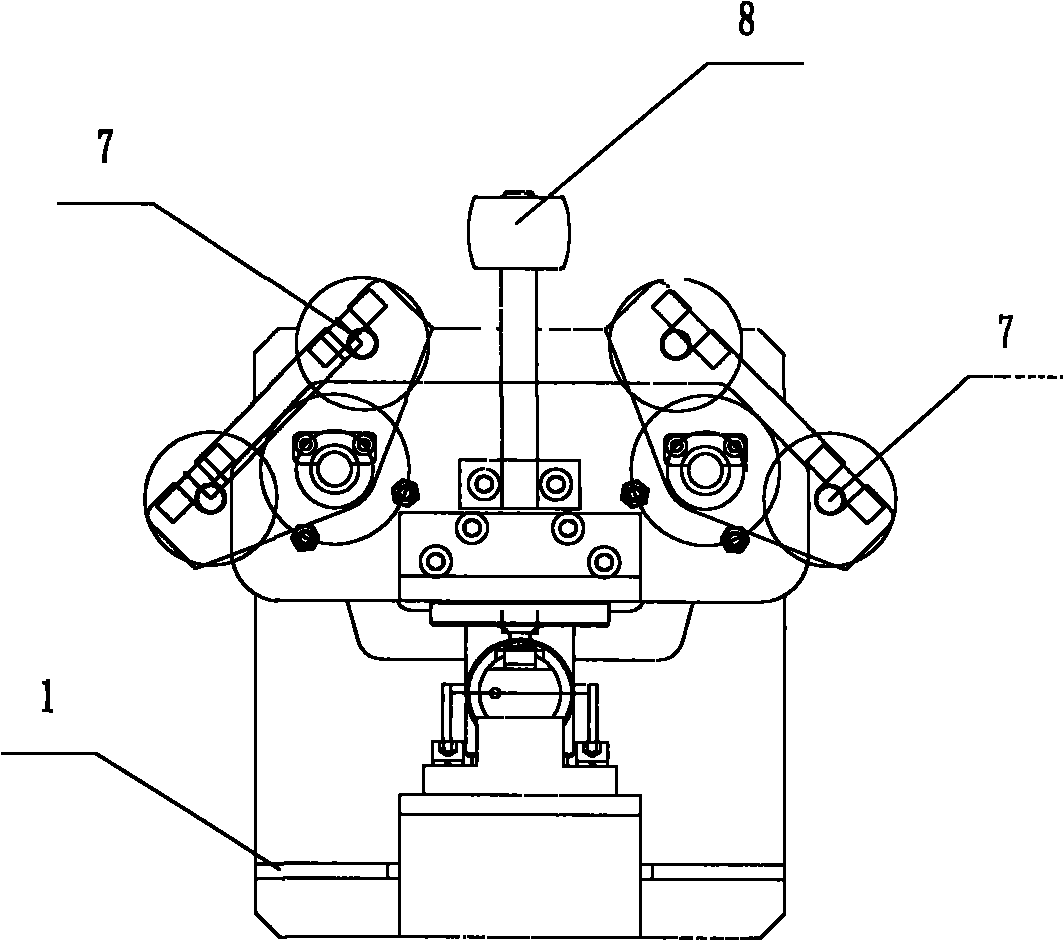

[0040] Example 1, such as Figure 1 to Figure 3 As shown, the tire unloading device for realizing on-line weighing measurement is applied and installed in the tire unloading station of the tire building machine. mainly include,

[0041] The hanger 11 connected to the tire building machine and used for lateral movement, the hanger 11 is buckled in the lateral chute (not shown in the figure) on one side of the tire building machine, and the drive mechanism on the side of the tire building machine drives the hanger 11 along the The transverse chute moves back and forth to drive the tire unloading device into and out of the tire unloading station.

[0042] The support 10 is vertically connected to the hanger 11 , and a cantilever 1 for unloading the green tire is provided at the lower end of the support 10 .

[0043] A vertical cylinder 13 is installed inside the bracket 10 , and one end connected to the cantilever 1 is driven to move vertically along the bracket 10 through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com