Method and apparatus for homogenizing a glass melt

一种玻璃液、搅拌装置的技术,应用在玻璃炉设备、玻璃制造设备、制造工具等方向

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

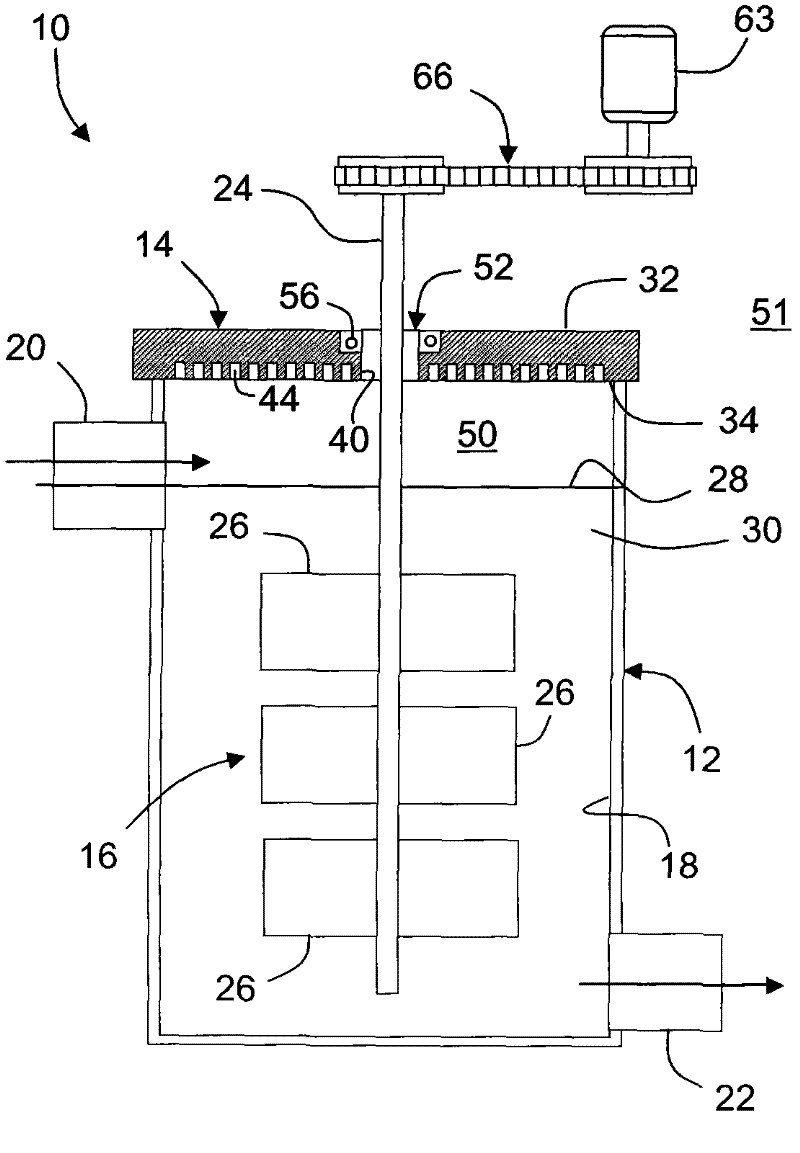

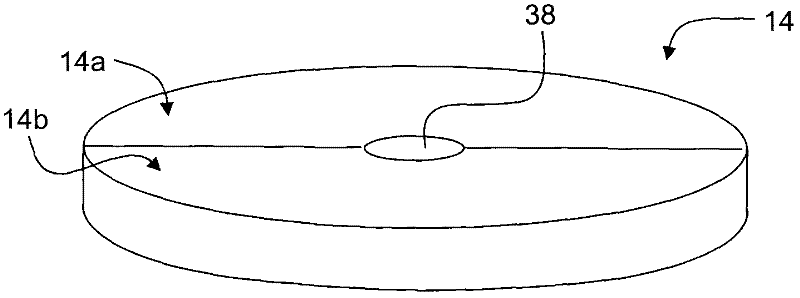

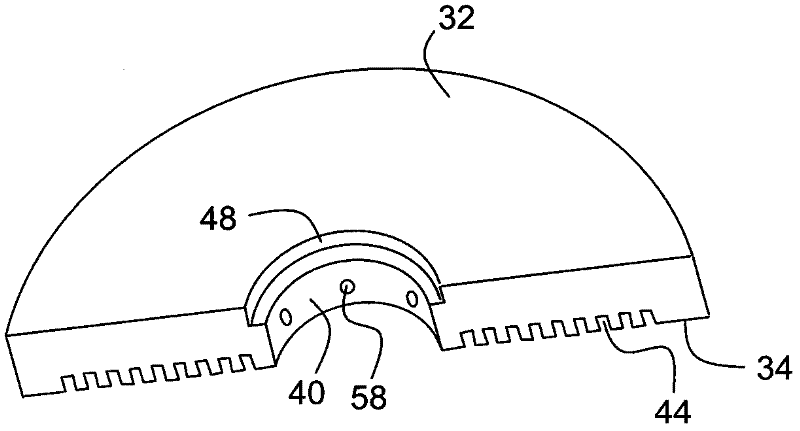

[0020] figure 1 An exemplary apparatus for carrying out a method of homogenizing a glass melt according to an embodiment of the present invention is shown. figure 1 The stirring device 10 comprises a stirring vessel 12, a stirring vessel cover 14 and a stirrer 16.

[0021] Stirring vessel 12 is preferably cylindrical in shape and generally vertically oriented, although the stirring vessel may have other shapes and orientations as desired. Preferably, the stirred vessel includes an inner surface 18 comprising platinum or a platinum alloy. Other materials having high temperature resistance, including corrosion resistance, and electrical conductivity may alternatively be used. For example, suitable metals for forming inner surface 18 may include other platinum group metals such as rhodium, iridium, palladium, ruthenium, osmium, and alloys thereof. The stirred vessel 12 includes a molten glass inlet pipe 20 located at or near the top of the stirred vessel 12 and a molten glass ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com