Continuous open width washing machine

A washing machine and open-width technology, which is applied in the direction of removing liquid/gas/steam with squeeze rollers, spraying/spraying textile material treatment, and treating textile material carriers, etc., which can solve the problems of reduced cleaning effect, no washing machine, and occupation of Dyeing machine and other problems, to achieve high cleaning efficiency, water saving, good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

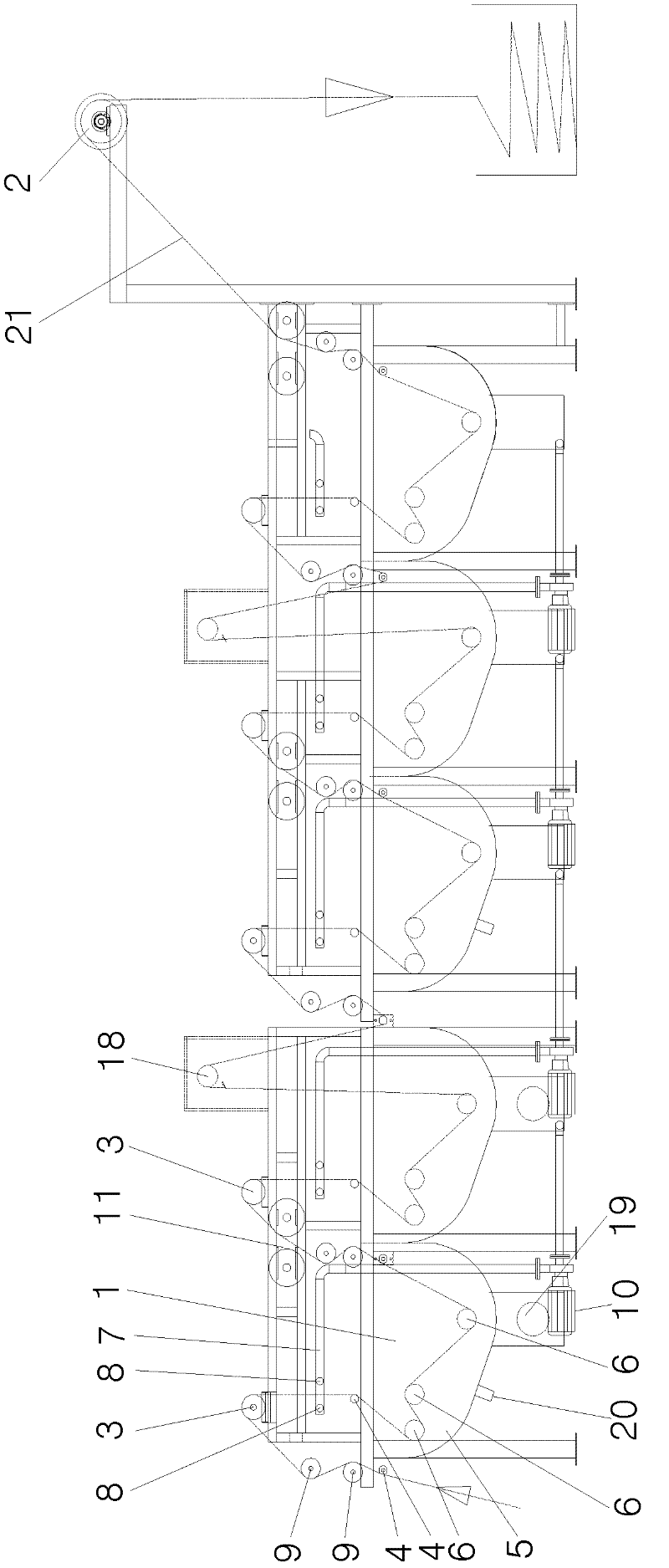

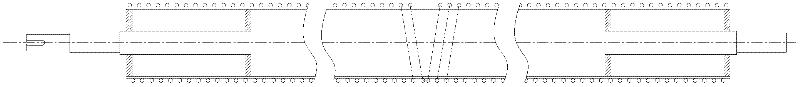

[0026] figure 1 The shown continuous open-width washing machine includes: a frame, five washing units 1 and a cloth outlet device. The washing water unit 1 and the cloth outlet device are all installed on the frame, and the five washing water units 1 are serially connected in sequence and then connected with the cloth outlet device. The cloth outlet device is a cloth outlet wheel 2 driven by a motor. The width of the cloth outlet wheel 2 is greater than that of the cloth piece 21. The structure of the cloth outlet wheel 2 is similar to that of a roller. The width mentioned here refers to the size of the cloth perpendicular to the paper surface.

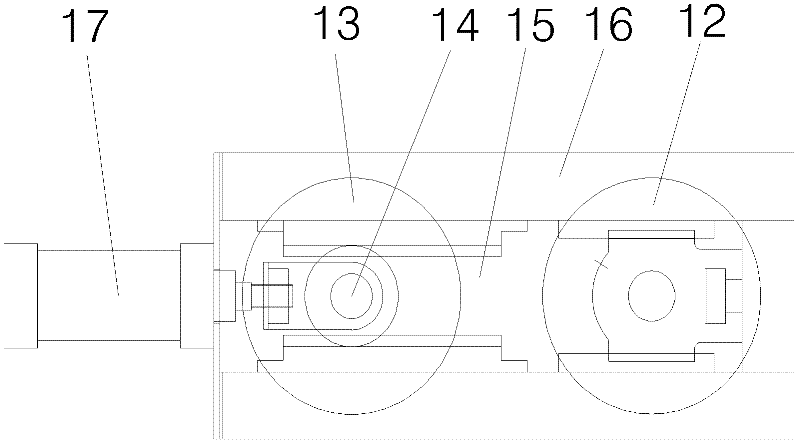

[0027] The washing unit 1 includes: a cloth lifting device, a washing tank 5 , a guide shaft 6 , a spraying device, a cloth spreading roller 9 and a cloth pressing wheel 4 . Wherein the cloth lifting device is a cloth lifting wheel 3 driven by a motor. The width of the cloth lifting wheel 3 is greater than the width of the cloth, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com