SCR (selective catalytic reduction) catalytic converter for diesel engine tail gas treatment

A catalytic converter and exhaust gas treatment technology, applied in the direction of machines/engines, chemical instruments and methods, mechanical equipment, etc., can solve the problems of system pressure loss, acoustic insertion loss, etc., and achieve good mixing performance, good flow performance, and pressure loss moderate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Method used

Image

Examples

Embodiment Construction

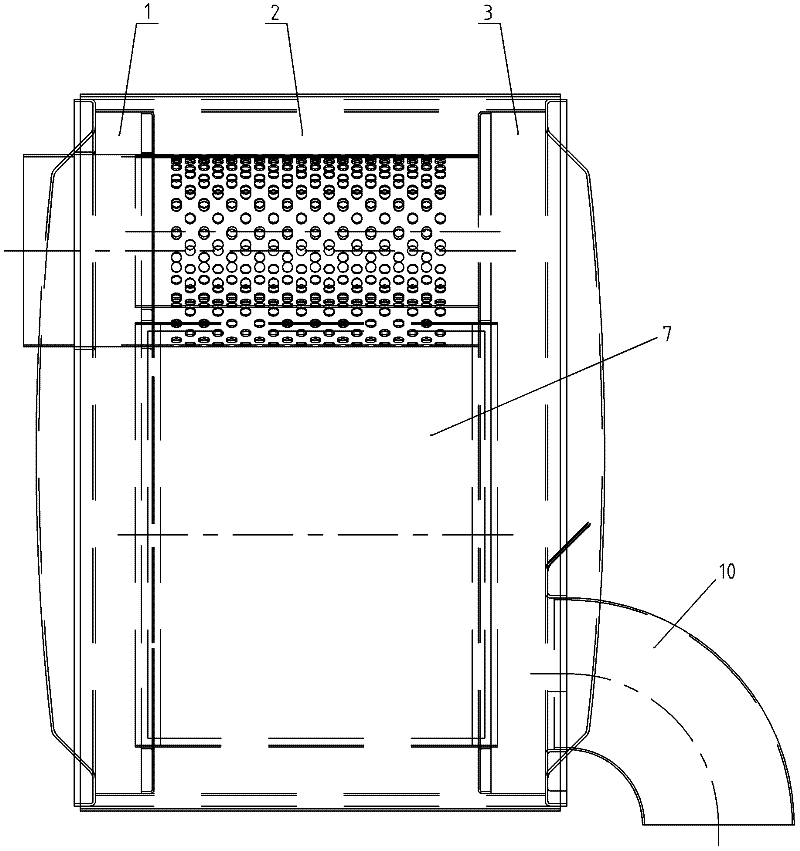

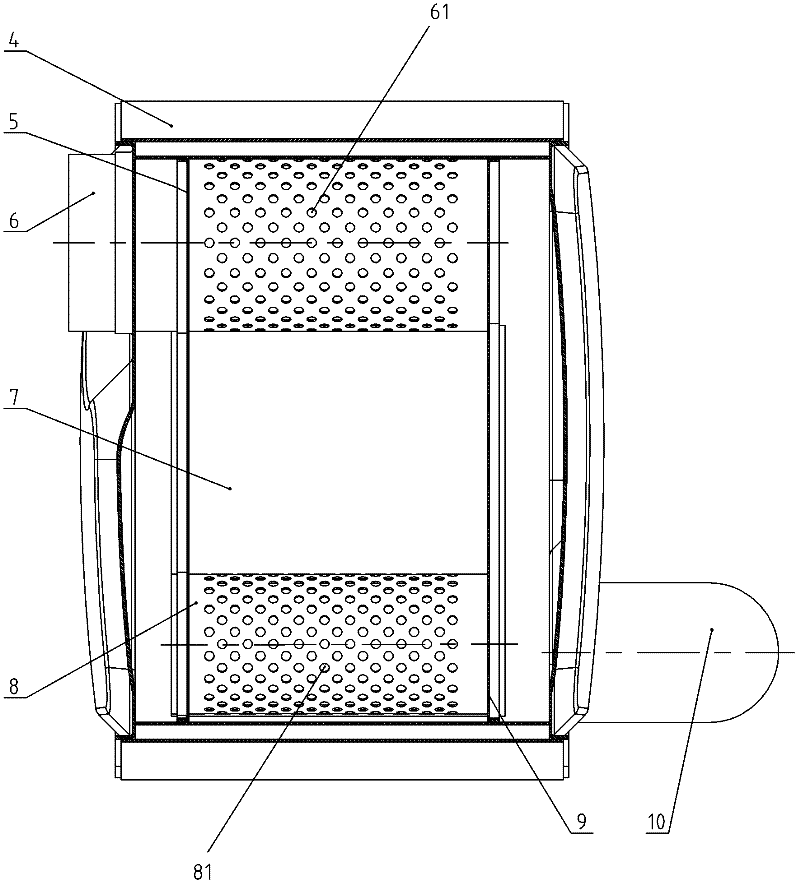

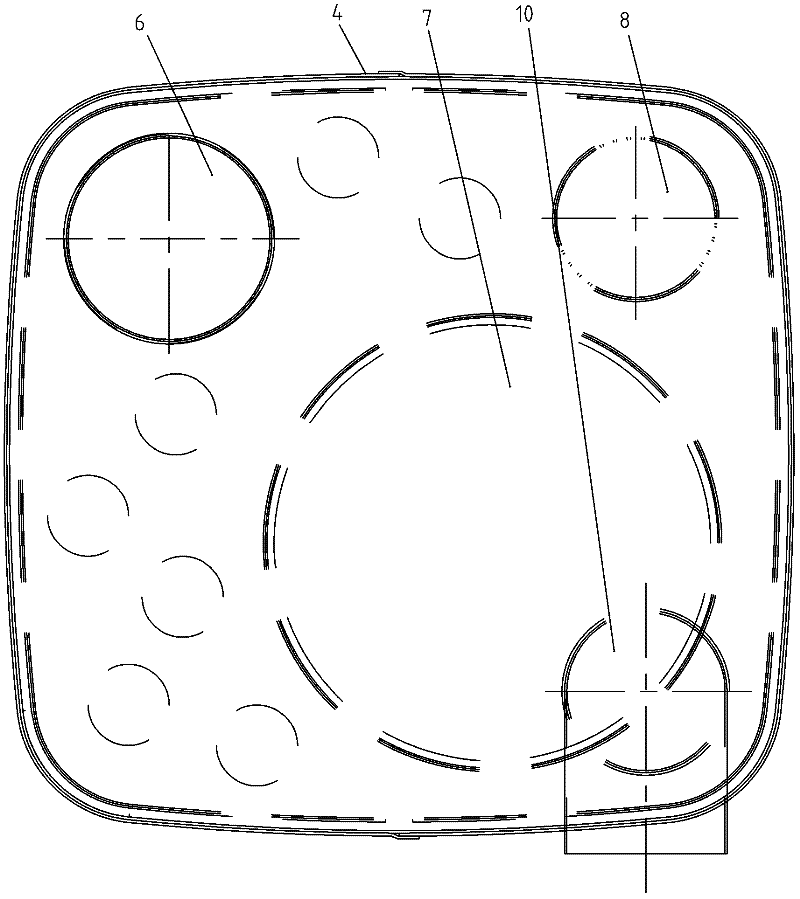

[0031] see figure 1 with figure 2 , an SCR catalytic converter for diesel engine exhaust treatment, including an intake chamber 1, a mixing chamber 2, an air outlet chamber 3, a housing 4, a left baffle 5, a gas inlet pipe 6, a catalyst carrier assembly 7, and a gas return pipe 8, right baffle plate 9, gas outlet pipe 10. The left baffle 5 and the right baffle 9 are installed in the housing 4 at intervals, and the housing 4 is divided into an air inlet chamber 1, a mixing chamber 2 and an air outlet chamber 3; the left baffle 5 separates the air inlet chamber 1 and the mixing chamber 2 , the left baffle 5 is provided with a plurality of openings, which can communicate the inlet chamber 1 and the mixing chamber 2; the right baffle 9 separates the mixing chamber 2 and the outlet chamber 3; the gas inlet pipe 6 is inserted from the upper left end surface of the housing Inside the housing, it passes through the left baffle 5 and is closed and connected with the right baffle 9. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com