Device and method for testing sound absorbing performance of material

A testing method and testing device technology, which is applied in the direction of using sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc., can solve problems such as large volume and limited test results, and achieve the effects of small size, wide application, and high testing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

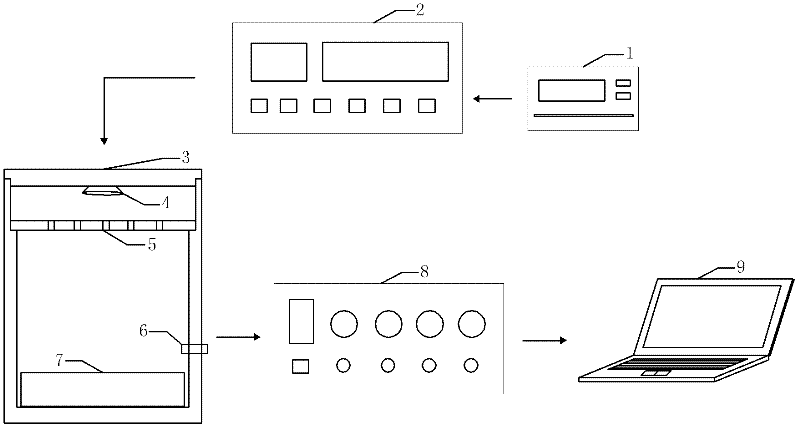

[0018] Specific implementation mode 1. Combination figure 1 Describe this specific embodiment, material sound-absorbing performance testing device, it comprises signal generator 1, power amplifier 2, sound insulation container 3, loudspeaker 4, sub-sound source partition 5, microphone 6, dynamic data acquisition instrument 8 and computer 9 ;

[0019] The inner wall of the sound insulation container 3 is provided with a shoulder, and the sub-sound source partition 5 is fixed on the shoulder, and the sound insulation container 3 is divided into upper and lower spaces, and the sub-sound source partition 5 and the sound insulation container 3 are parallel to the bottom surface, the test piece 7 is arranged on the bottom surface in the lower space of the sound insulation container 3, the microphone 6 is arranged between the sub-sound source partition 5 and the test piece 7, and the microphone 6 penetrates the side of the sound insulation container 3 The wall is fixed on the side w...

specific Embodiment approach 2

[0022] Embodiment 2. The difference between this embodiment and the device for testing the sound absorption performance of materials described in Embodiment 1 is that the sub-sound source partition 5 is a perforated steel plate with a thickness of 20 mm to 30 mm.

[0023] This embodiment is a small-volume diffuse-incidence sound absorption coefficient measuring device. In this embodiment, in order to generate a diffuse sound field in a small space, a porous thin steel plate is arranged under the sound source, and the diffraction effect of sound waves is used to transform one sound source into multiple irregular sound sources after being diffracted by the thin plate. The sound field generated by the superposition of multiple sound sources is a diffuse field, and the sound absorption performance test of the material is realized under the action of the diffuse field.

[0024] In this embodiment, steel with relatively high rigidity and specific gravity is used as the main material...

specific Embodiment approach 3

[0025] Embodiment 3. Based on the method for testing the sound absorption performance of materials described in Embodiment 1, it is realized by the following steps:

[0026] Step 1, using the signal generator 1 to generate a simple harmonic voltage signal of 50 Hz to 20000 Hz;

[0027] Step 2, the signal generated in step 1 is amplified by power amplifier 2, and the amplified signal is output through speaker 4;

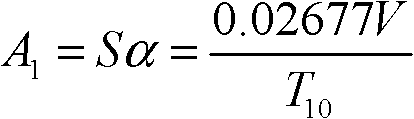

[0028] Step 3, using the data acquisition instrument 8 to collect the time T used for the sound intensity in the sound insulation container 3 to attenuate by 10dB 10 , via the formula:

[0029] A 1 = Sα = 0.02677 V T 10

[0030] Calculate the sound absorption A of the sound insulation container 3 in the state of no test piece 1 ;

[0031] Among them: V is the volume of the sound insulation container...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com