Graded dehydration system and method of ceramic filter

A ceramic filter, system equipment technology, applied in the direction of filtration separation, separation method, filtration loop, etc., to achieve the effect of reducing the input of labor and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

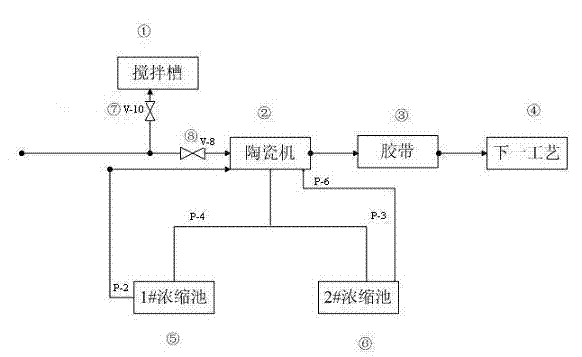

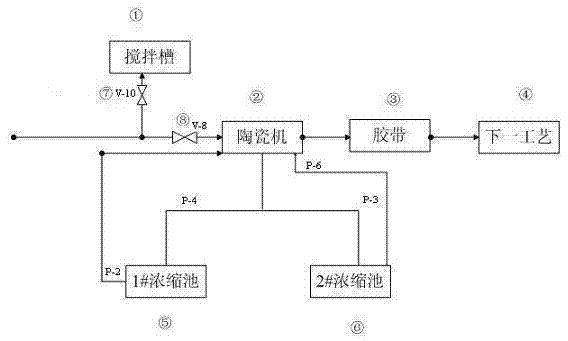

[0022] In order to avoid the mixing of two grades of ore pulp in the thickening tank during graded ore delivery, the ceramic filter graded dehydration system of the present invention is adopted, and the system includes: ceramic filter 2 dehydration system and the matching thickening tank 1﹟5, also includes The stirring tank 1 switched with the main pipeline and the concentration pool 2﹟6 matched with the ceramic filter 2 dehydration system. It also includes a conveyor belt 3 connected with the ceramic filter.

[0023] The pulp A with a grade of 55% and the pulp B with a grade of 64% are two kinds of pulp that are transported in pipelines in stages. The ceramic filter 2 graded dehydration system of the present invention is used to carry out graded dehydration of the two pulps, and the operations are carried out according to the following steps : (1) The valve 8 of the factory building is turned on, the main valve 7 is closed, and the ore slurry A arriving at the dehydration sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com