Material weighing and variable-speed conveying system for blast furnace

A technology of variable-speed conveying and material, applied in conveyor objects, conveyor control devices, transportation and packaging, etc., can solve the problems of reducing students' enthusiasm for learning, difficult students, inconvenient processing and production, etc., to exercise hands-on ability and teamwork. Coordination ability, good hands-on ability and team coordination ability, the effect of improving understanding and mastery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

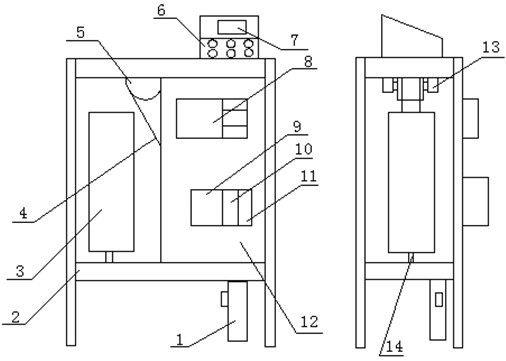

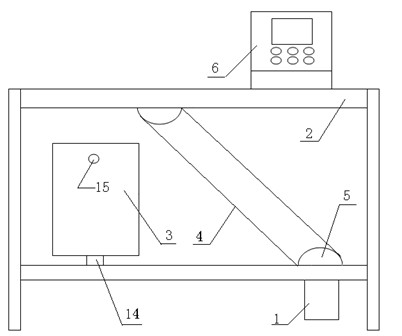

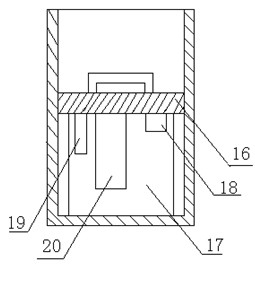

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

[0025] Such as Figure 1-3 As shown, a blast furnace material weighing and variable speed conveying system includes a device frame 2, a material bin 3 and a material conveying device. A material bin 3 is arranged in the device frame 2, and the outlet of the material conveying device is connected to the inlet of the material bin 3. Corresponding. The material conveying device includes a motor 1, a reducer, a belt 4 and two pulleys 5, a pulley 5 is respectively arranged at the top and bottom of the device frame 2, and a pulley bearing 13 is arranged outside the pulley 5. During design, two belt pulleys 5 are arranged obliquely and are connected by belt 4, and motor 1 is arranged below the bottom of device frame 2, and motor 1 is connected with the rotating shaft of bottom belt pulley 5 through speed reducer. The device conveys materials through the belt 4, and the moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com