Dual components condensed type room temperature cured high conductive silicone rubber adhesive and application method thereof

A room temperature curing, condensation type technology, used in conductive adhesives, non-polymer adhesive additives, adhesives, etc., can solve the problem of inability to deep cure, and achieve the effect of good elasticity, wide application range and excellent electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

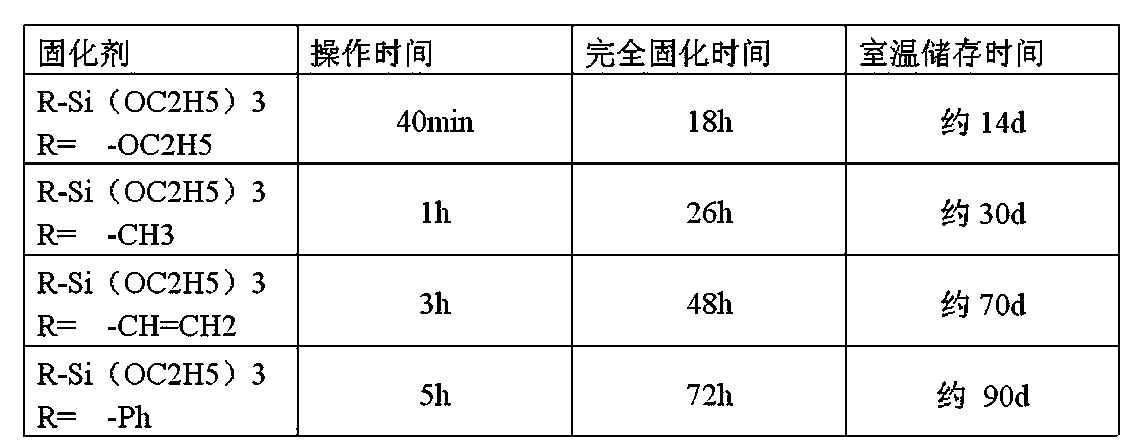

Method used

Image

Examples

example 1

[0039] Production of component A: In a dry and clean container, uniformly mix the following components: 1000 parts by weight of spherical copper powder with a diameter of 1000nm, 100 parts by weight of hydroxyl-terminated polysilicon with a viscosity of 1000cp and a hydroxyl content of 0.10%. A mixture of oxanes, 10 parts by weight of dibutyltin diacetate catalyst. After mixing, a viscous liquid with a viscosity of 100000cp~150000cp is obtained and stored in a sealed container.

[0040] Production of component B: In a dry and clean container, uniformly mix the following components: 1000 parts by weight of spherical copper powder with a diameter of 1000nm, 100 parts by weight of hydroxyl-terminated polysilicon with a viscosity of 1000cp and a hydroxyl content of 0.10%. A mixture of oxanes, 10 parts by weight of fumed silica, and 10 parts by weight of methyltriethoxysilane curing agent. After mixing, a viscous liquid with a viscosity of 100000cp~150000cp is obtained and stored ...

example 2

[0043] Preparation of component A: In a dry and clean container, uniformly mix the following components: 700 parts by weight of flaky silver powder with a diameter of 5000nm, 100 parts by weight of hydroxyl-terminated polysilicon with a viscosity of 10000cp and a hydroxyl content of 0.04%. The mixture of oxane, the dibutyltin dilaurate catalyst of 1 weight part. After mixing, a viscous liquid with a viscosity of 80000cp~120000cp is obtained and stored in a sealed container.

[0044] Production of component B: In a dry and clean container, uniformly mix the following components: 700 parts by weight of flaky silver powder with a diameter of 5000nm, 100 parts by weight of hydroxyl-terminated polysilicon with a viscosity of 10000cp and a hydroxyl content of 0.04%. A mixture of oxanes, without functional fillers, and 20 parts by weight of tetraethyl silicate curing agent. After mixing, a viscous liquid with a viscosity of 80000cp~120000cp is obtained and stored in a sealed contain...

example 3

[0047] Production of component A: In a dry and clean container, uniformly mix the following components: 800 parts by weight of spherical silver-coated glass powder with a diameter of 200nm, 100 parts by weight of hydroxyl-terminated glass powder with a viscosity of 3000cp and a hydroxyl content of 0.08%. Mixture of polysiloxanes, 5 parts by weight of dibutyltin (β-diketone ester) catalyst. After mixing, a viscous liquid with a viscosity of 150000cp~190000cp is obtained and stored in a sealed container.

[0048] Production of component B: In a dry and clean container, uniformly mix the following components: 800 parts by weight of spherical silver-coated glass powder with a diameter of 200nm, 100 parts by weight of hydroxyl-terminated glass powder with a viscosity of 3000cp and a hydroxyl content of 0.08%. A mixture of polysiloxanes, 5 parts by weight of KH-560, 5 parts by weight of fumed silica, and 5 parts by weight of vinyltriethoxysilane curing agent. After mixing, a viscou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com