Automatic gas diluter

A diluter and automatic technology, applied in the direction of gas discharge, safety devices, mining equipment, etc., can solve the problems of high cost and complex structure, and achieve the effects of low production cost, simple structure, good sealing and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

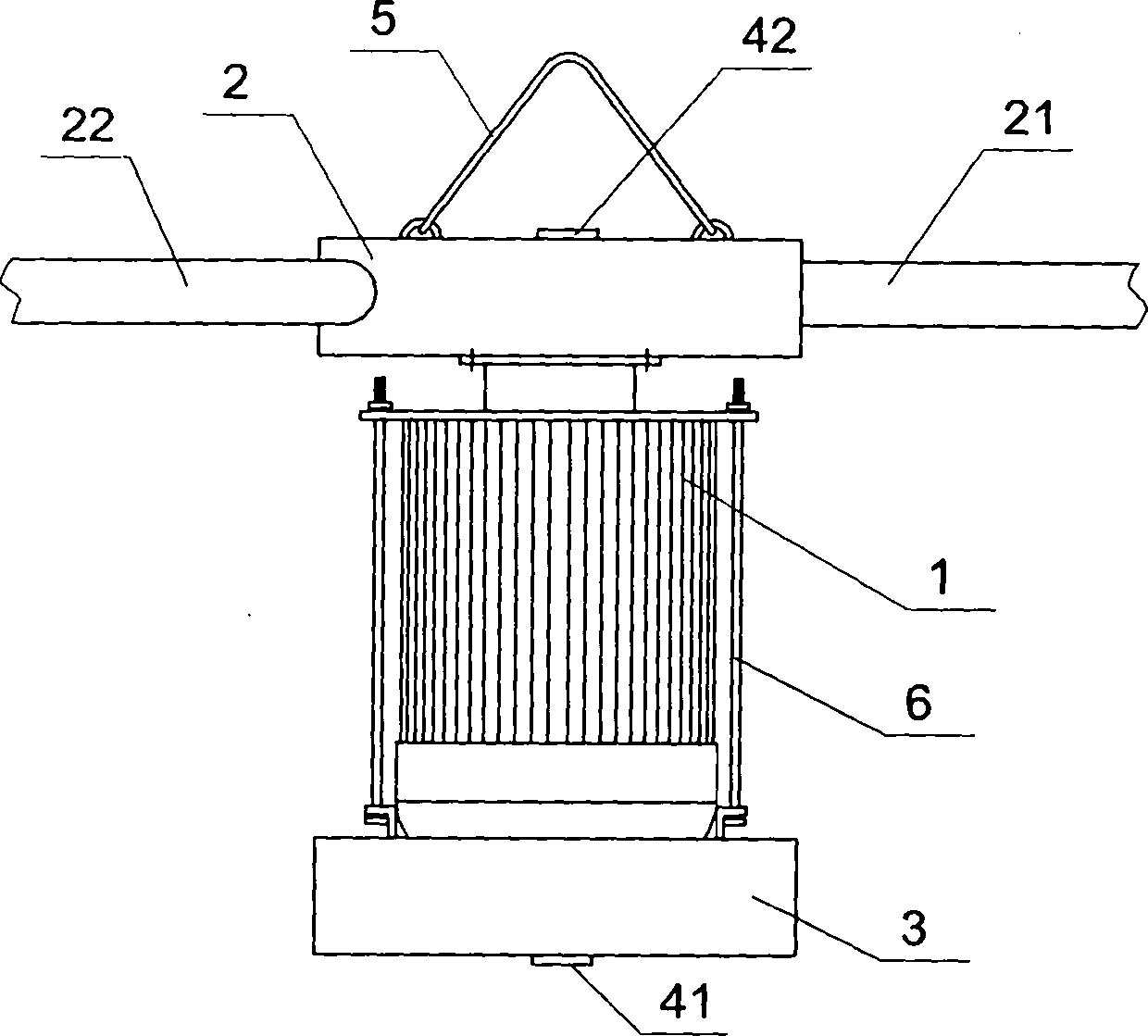

Embodiment 1

[0020] Embodiment one: see figure 1 , a gas automatic diluter, the fan includes a motor 1 and a wind turbine chamber 2. The output shaft of the motor 1 is connected to the turbine drive in the wind turbine chamber 2 upwards, and a hook 5 is arranged above the wind turbine chamber 2. After the top of the upper corner is punched and the hook is fixed, the hook 5 is hung on the hook. The lower part of the motor 1 is fixed with a battery casing 3 through a support rod 6, and a battery and a control circuit board are hermetically installed in the battery casing 3. Gas concentration sensors 41 and 42 are respectively installed on the battery casing 3 and the wind turbine chamber casing 2, the gas concentration sensor is sealed and connected to the input end of the control circuit board, the battery is sealed and connected to the control circuit board, and the output of the control circuit board The end is sealed with the motor input end. Motor 1 adopts explosion-proof motor.

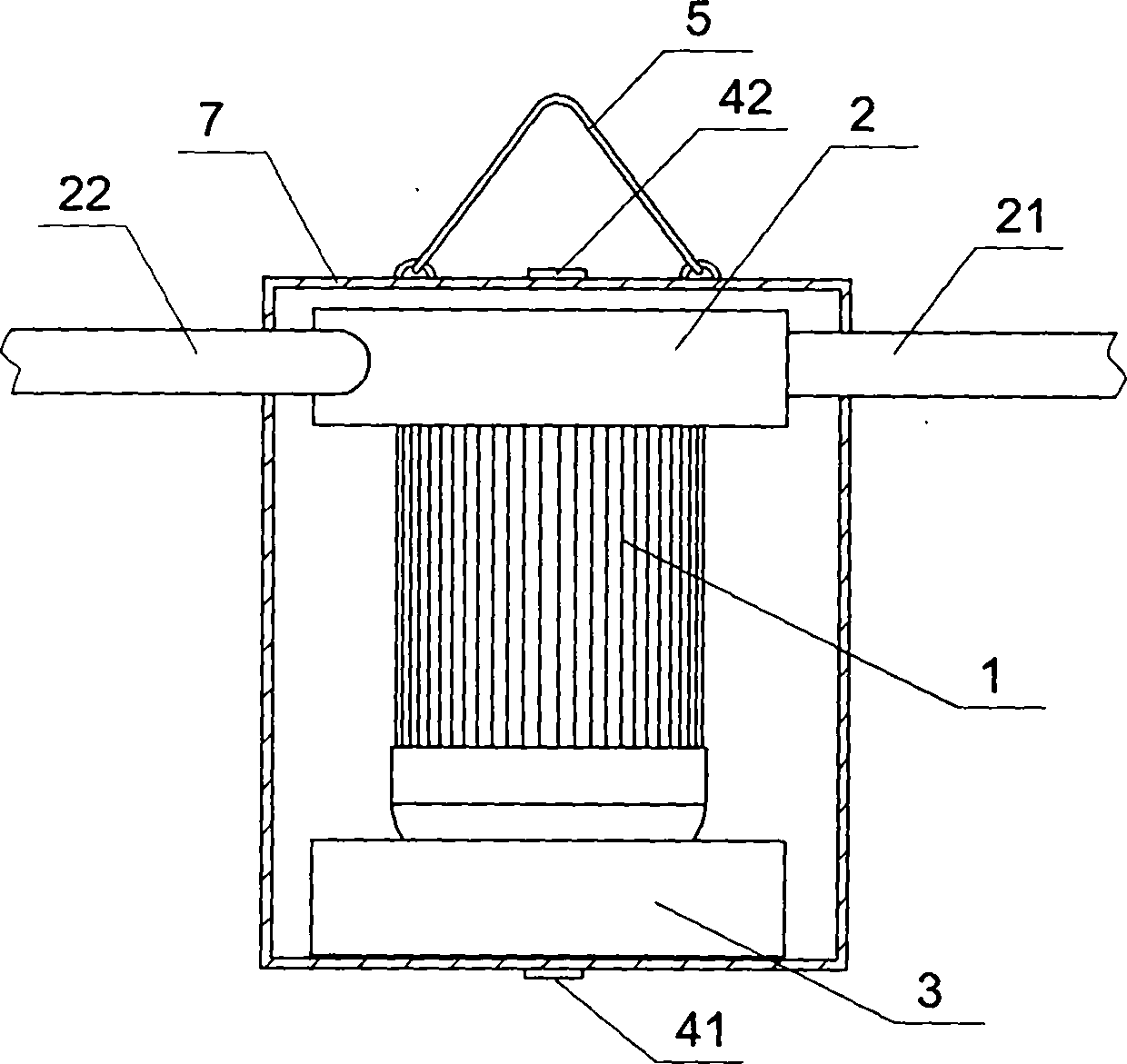

Embodiment 2

[0021] Embodiment two: see figure 2 , another gas automatic diluter, the content is basically the same as that of Embodiment 1, and the similarities will not be repeated. The difference is that it also includes an airtight support shell 7, and the battery, motor and wind turbine chamber are installed on the support In the casing, there may be multiple probes of the gas concentration sensor, which are respectively located on the side walls of the airtight casing. The upper part of the airtight casing is fixed with a buckle 5, and the air inlet pipe 21 and the air outlet pipe 22 of the wind turbine chamber are respectively fixed on the left and right side walls of the supporting casing. Due to the function of the airtight supporting shell, the motor can be an explosion-proof motor or an ordinary motor.

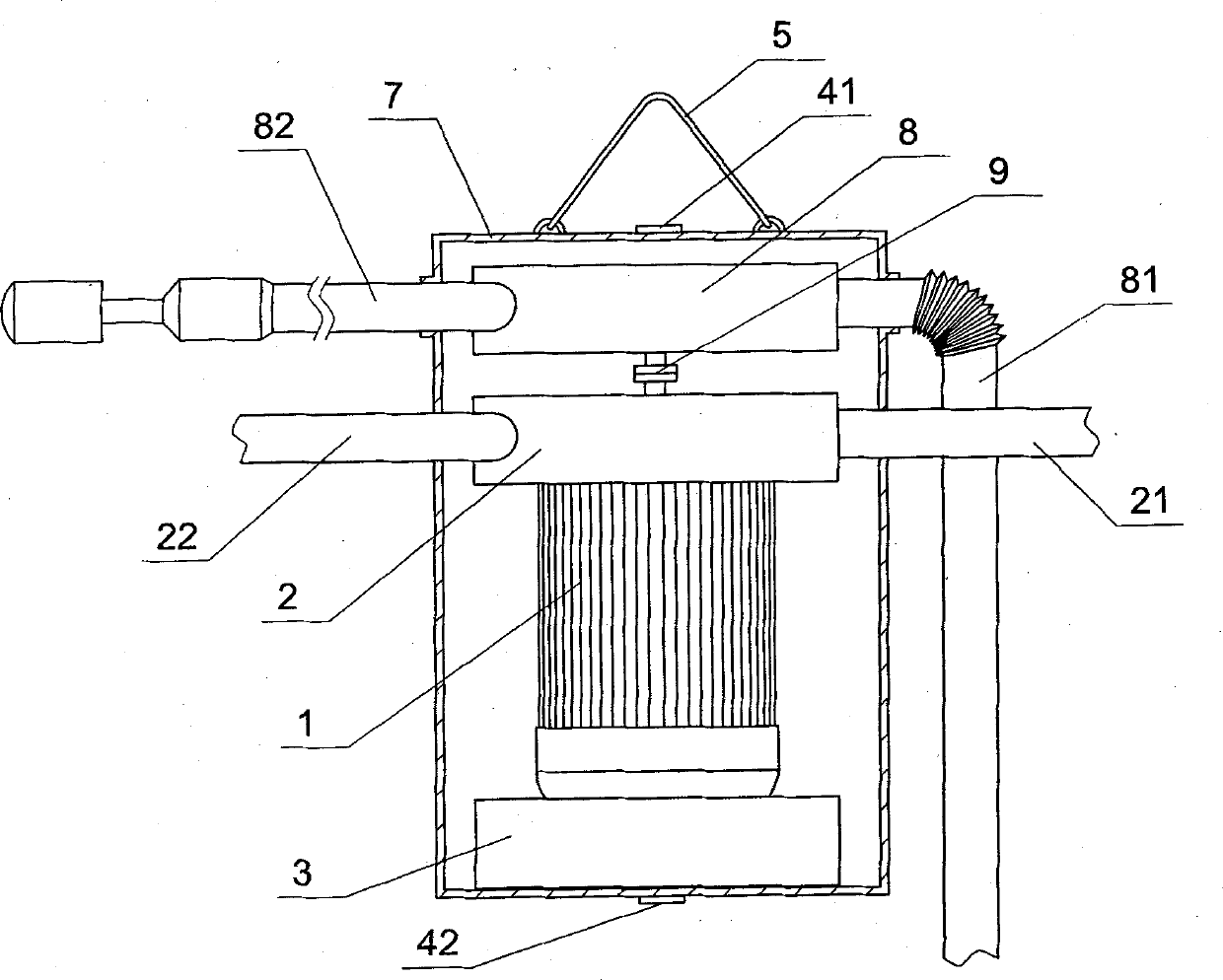

Embodiment 3

[0022] Embodiment three: see image 3 , another kind of gas automatic diluter, the content is basically the same as that of Embodiment 2, and the similarities will not be repeated. A water turbine chamber 8 is also arranged in the airtight support shell 7, and the output shaft of the motor is connected with the wind turbine chamber 2 and the water turbine chamber simultaneously. The turbine transmission in the turbine chamber 8 is connected, and the water inlet pipe 81 and the water outlet pipe 82 of the water turbine chamber 8 are respectively fixed on the side walls of the supporting shell, and the water inlet pipe can be communicated with the water container on the ground. In this embodiment, an electric clutch 9 is installed on the transmission shaft between the wind turbine chamber 2 and the water turbine chamber 8, and the signal line of the electric clutch 9 is sealed and connected with the output end of the control circuit board. The water outlet pipe 82 is a jet water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com