Bottom case of kitchen range and kitchen range with same

A cooker and bottom case technology, which is applied in the field of cooker bottom case, can solve the problem of the high overall cost of cooktops, and achieve the effects of shortening processing and manufacturing time, saving costs, and reducing mold cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the object, scheme and beneficial effect of the present invention more clear, the present invention will be further described below in conjunction with the accompanying drawings and preferred embodiments.

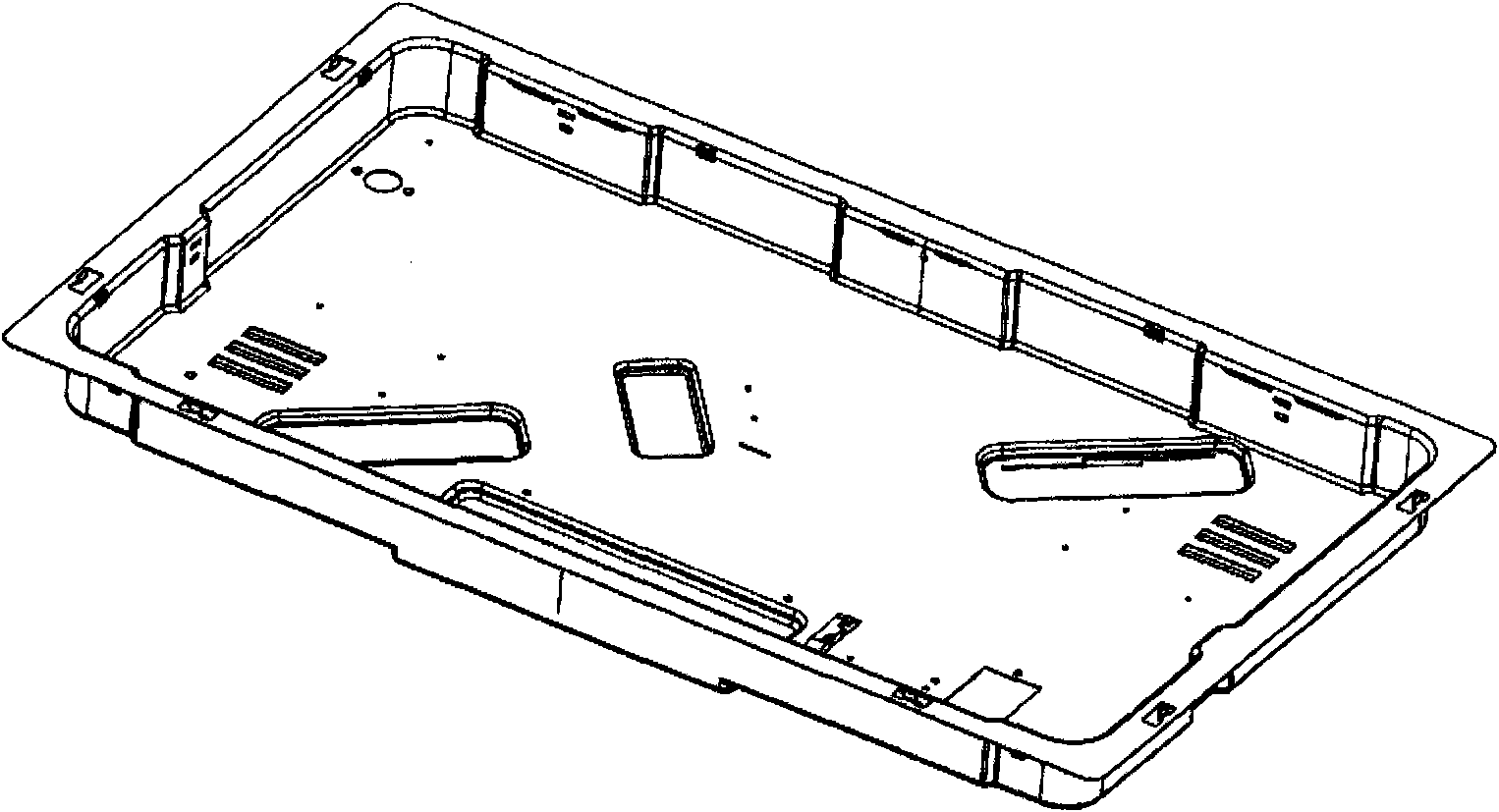

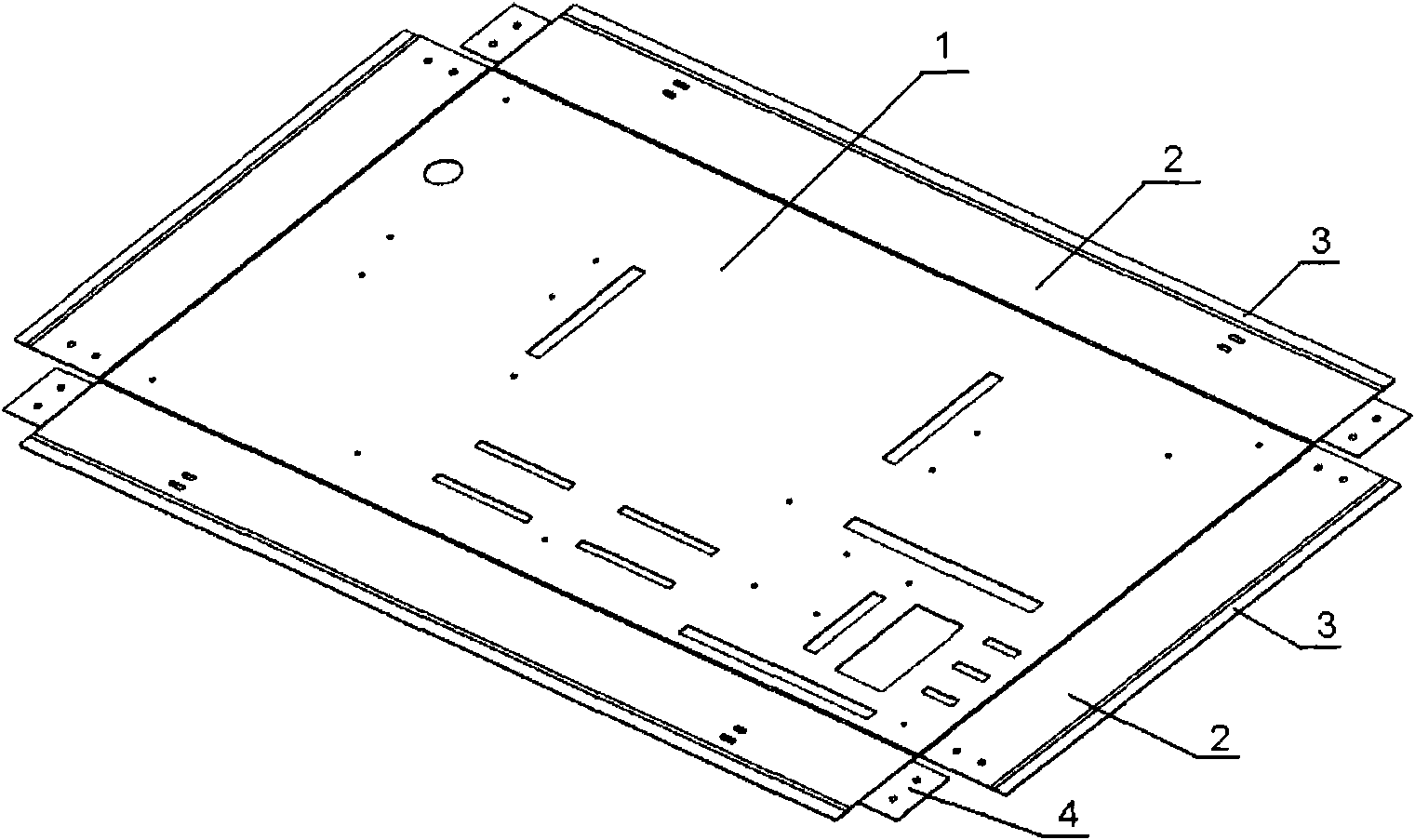

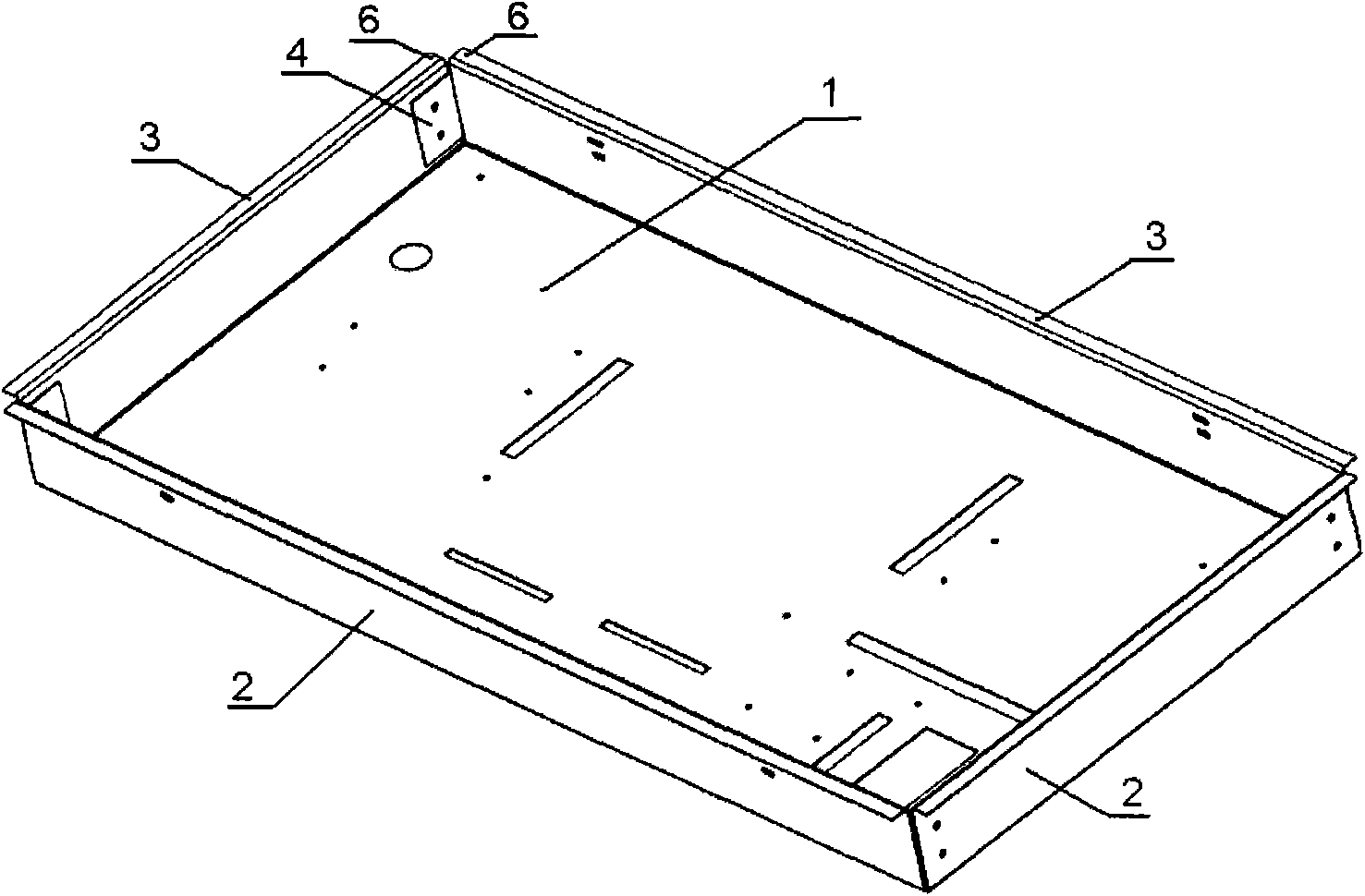

[0034] The present invention provides an embodiment of a cooker bottom case, which is formed by bending a metal plate. Specifically, firstly, a whole plate is punched into a metal plate before being bent, and then the metal plate is bent and further processed by a bending die to be made into a cooker bottom case. The metal plate includes a base plate 1 and extensions 2 connected to each side of the base plate 1 . Each extension part 2 is used to form the side wall of the cooker bottom case after being bent respectively. The bottom plate 1 is used as the bottom wall of the cooker bottom case. Horizontal flanging is respectively arranged on each side wall, and an included angle is formed between the ends 6 of two adjacent flangings. The cooker botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com