Defect point locating method of semiconductor device

A positioning method and defect point technology, applied in the field of semiconductor device defect point positioning, can solve the problems of complicated installation and debugging, reduce failure analysis efficiency, increase failure analysis cost, etc., and achieve the effect of improving efficiency and reducing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

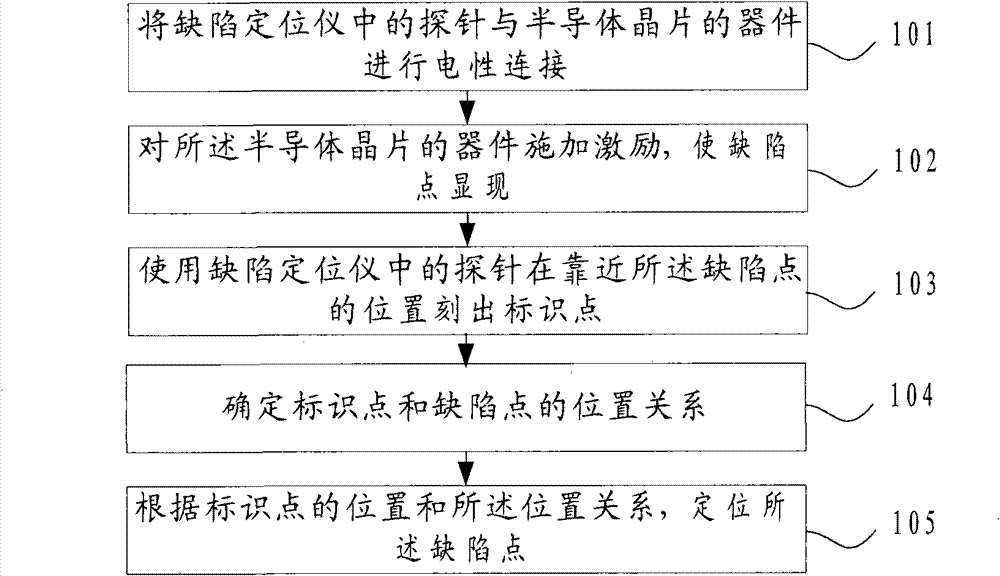

[0051] figure 1 It is a schematic flow chart of a method for locating a defect point of a semiconductor device provided in Embodiment 1 of the present invention. The method specifically may include the following steps:

[0052] Step 101 , electrically connect the probes in the defect locator to the devices of the semiconductor wafer.

[0053] Load the semiconductor wafer into the defect locator, and configure the probes in the defect locator; by adjusting the position angle of the semiconductor wafer on the tray and the position of the probes, the probes at different positions correspond to the devices in the semiconductor wafer. Make physical and electrical contact.

[0054] Step 102, applying excitation to the devices of the semiconductor wafer to make defect points appear.

[0055] Turn on the power signal line to apply excitation to the devices in the semiconductor wafer, so that the defect points appear; when the power signal is turned on, the probe transmits the test ...

Embodiment approach

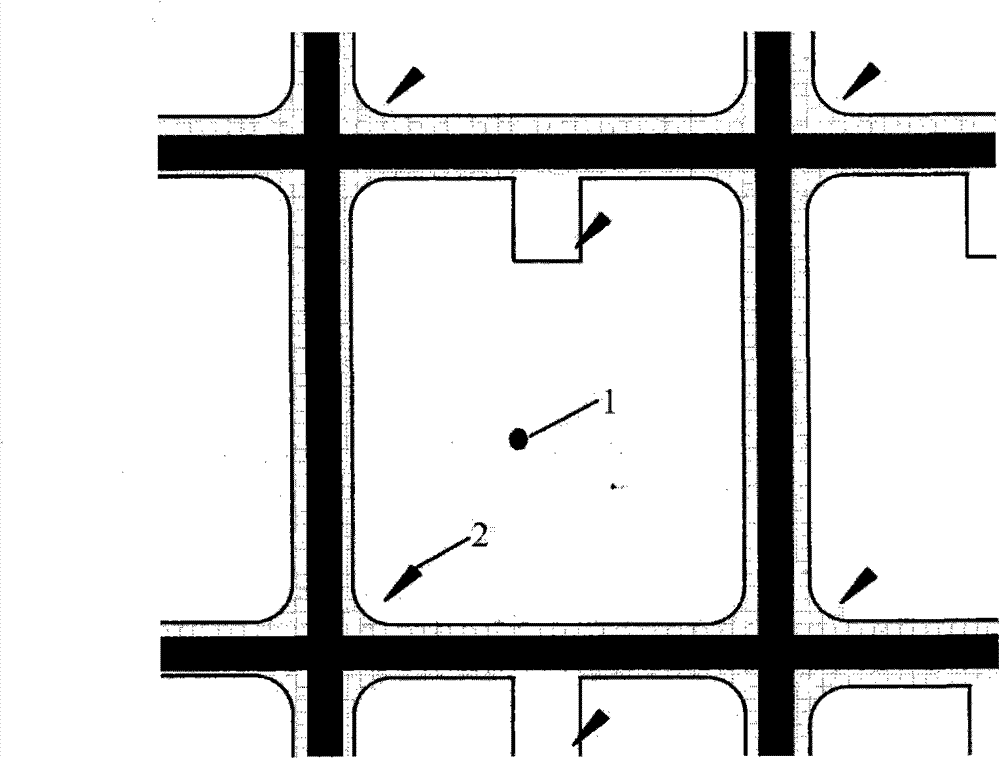

[0071] One: use the probe to carve a mark point at a position close to the defect point to carve a mark point.

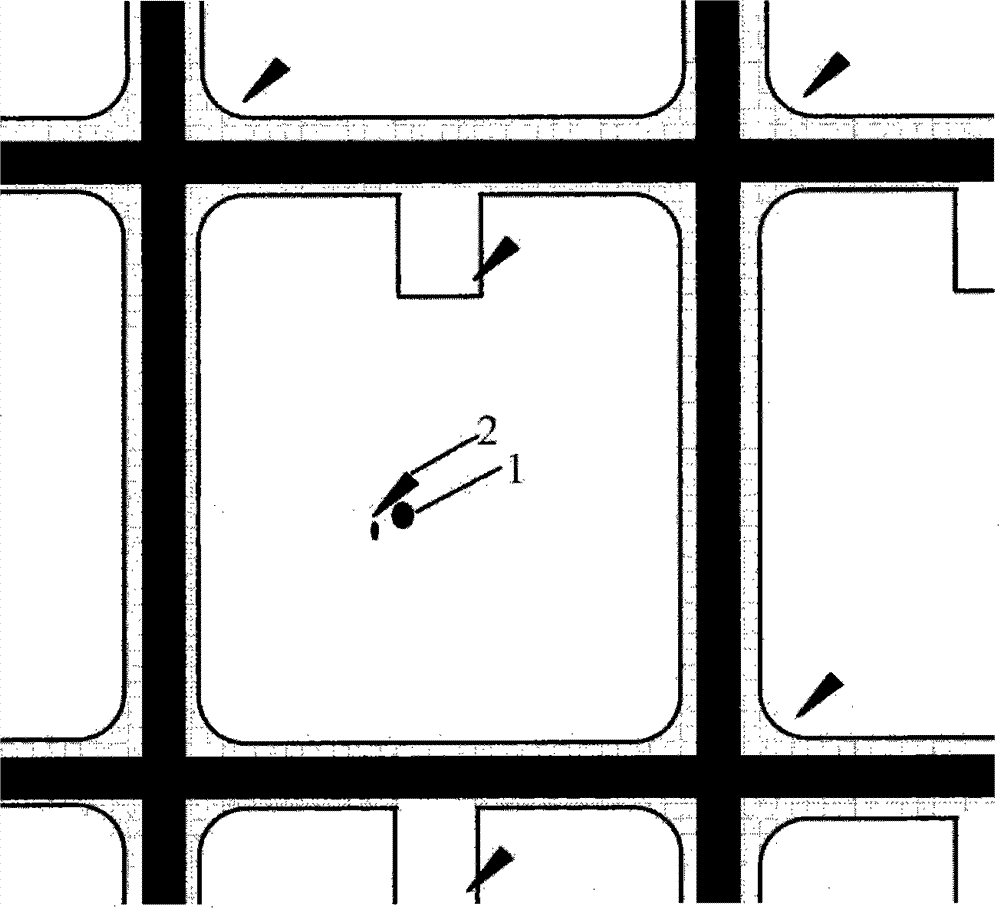

[0072] Two: use the probe to carve out marking points at a position close to the defect point and carve at least two marking points.

[0073] Wherein, using the probe to engrave at least two identification points at a position close to the defect point can be achieved in the following manner:

[0074] Use the probe to carve out a mark point at a position close to the defect point to carve out a mark point;

[0075] moving the probe back to the initial position, and applying excitation to the device in the semiconductor wafer again to make the defect point appear again;

[0076] Using the probe again to engrave a marker point at a position close to the defect point to engrave a second marker point;

[0077] Repeat the above steps to set multiple identification points for a defect point as required.

[0078] Taking the device in the semiconductor wafer as an exampl...

Embodiment 3

[0086] In Embodiment 1, in the step of applying excitation to the device of the semiconductor wafer to make the defect point appear, when at least two defect points appear, the probe in the defect locator is at a position close to the defect point The step of engraving the marking point may specifically include:

[0087] Move the probe in the defect locator to a position close to one of the defect points;

[0088] Mark a marker point at the location using the probe;

[0089] moving the probe back to its initial position;

[0090] Apply excitation to the devices of the semiconductor wafer again to make the defect point appear again;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com