Multi-wavelength laser generation unit

A generation device, multi-wavelength technology, used in lasers, laser parts, phonon exciters, etc., can solve problems such as large volume and complex structure, and achieve the effects of high mechanical efficiency, reliable operation and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

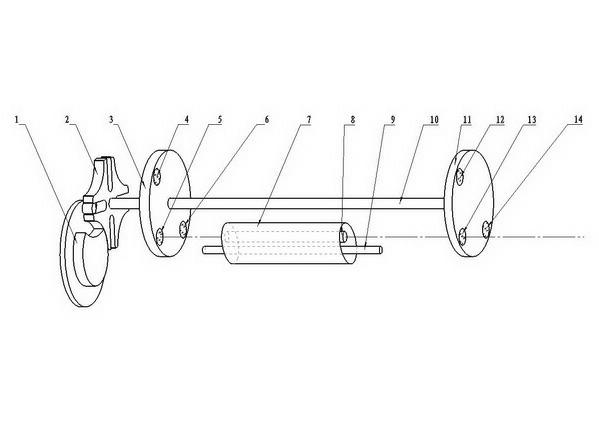

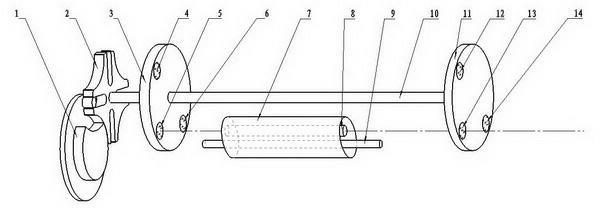

[0017] When there are 4 long slots in the sheave, the combination of three groups of lenses is an example to illustrate the present invention:

[0018] like figure 1 As shown, dial 1 is placed on the left side of focusing cavity 7, sheave 2, total reflection lens mounting plate 3, total reflection lens I, II, III are placed on total reflection lens mounting plate 3, and in focusing cavity 7 A laser source 9 and a round rod 8 containing a laser working substance are included, and a light-emitting lens mounting plate 11 is placed on the right side of the light-gathering cavity, and the semi-transparent and semi-reflective lenses I, II, and III are placed on the light-emitting lens mounting plate 11; each The lenses are individually adjustable so that each set of lenses can be precisely aligned to meet the conditions for laser generation.

[0019] When the dial 1 rotates, it drives the sheave to rotate, and the locking arc is just in the disengaged state. The cylindrical pin on...

Embodiment 2

[0025] When the sheave 2 has 3 long grooves, such as figure 1 As shown, the multi-wavelength laser generating device consists of a set of groove wheel intermittent mechanism, a full-reflective lens mounting plate, a semi-transparent and semi-reflective lens mounting plate, a rigid shaft, and a concentrator containing laser working material and laser source (lamp). The optical cavity is composed of multiple sets of reflective lenses; its feature is that multiple sets of movable full-reflective lenses or semi-transparent and semi-reflective lenses are set in a fixed light-gathering cavity, and a sheave intermittent mechanism is set inside to control the movement of the lenses;

[0026] When working, the sheave mechanism can convert the constant-speed rotary motion of the dial 1 into the intermittent rotary motion of the sheave 2, which moves and stops. Place the groove wheel mechanism, the full-reflection lens mounting plate 3, the laser source 9 in the light-condensing cavity ...

Embodiment 3

[0030] A multi-wavelength laser generating device, including a sheave intermittent mechanism composed of a dial 1 and a sheave 2, a light collecting cavity 7 composed of a round rod 8 containing a laser working substance, and a laser source 9, two of which are respectively placed in the light collecting cavity 7 The reflecting mirrors on both sides are equipped with discs, multiple groups of total reflecting mirrors and half reflecting mirrors with different parameters, the number of reflecting mirror groups is equal to or less than the number of grooves of the sheave 2. The sheave 2 of the sheave mechanism, the full-reflection lens mounting plate 3, and the light-emitting lens mounting plate 11 are coaxial and rigidly connected. The total reflection mirror and the half reflection mirror are respectively placed on the total reflection mirror mounting plate 3 and the light-emitting lens mounting plate 11, and the center of the disc is the origin, the distance from the origin is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com