Underground cylindrical linear motor stator

A linear motor, cylindrical technology, used in electrical components, electromechanical devices, electric components and other directions, can solve the problems of poor water pressure resistance, poor sealing performance, poor heat dissipation performance, etc., to achieve reliable sealing and increase insulation performance. , The effect of improving heat dissipation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

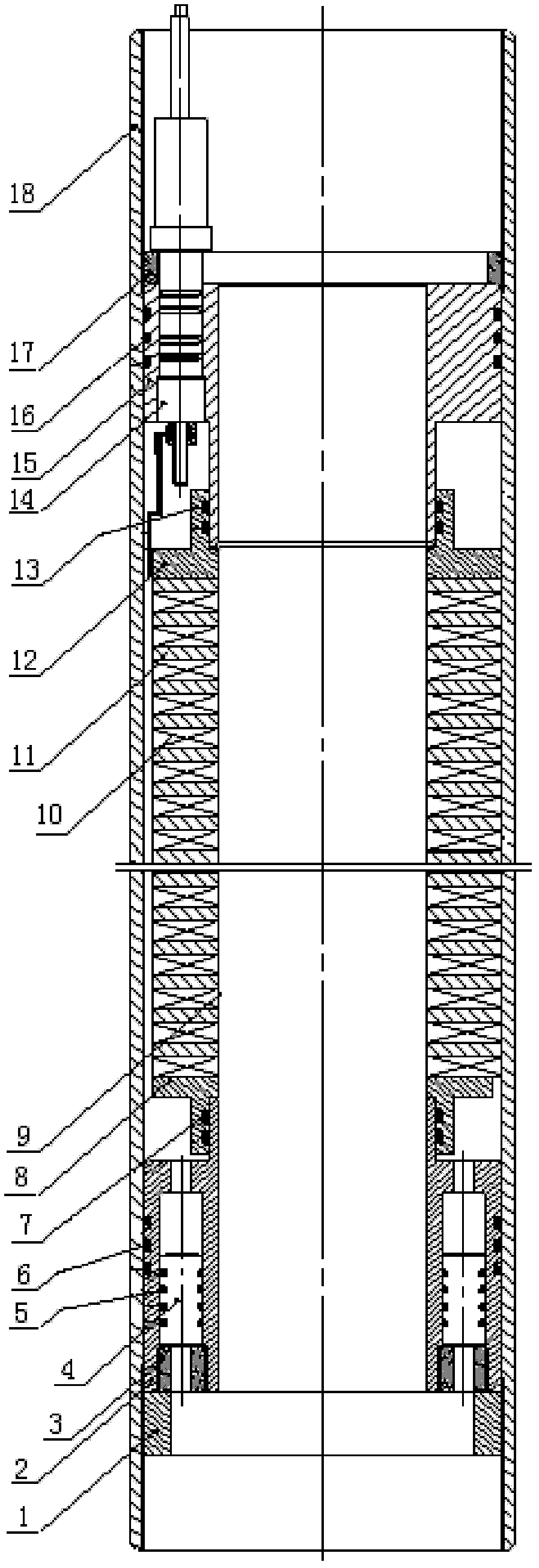

[0019] Embodiment 1: Taking a linear motor stator with a depth of 1000m used in an oil well with an inner diameter of 124mm as an example, the present invention will be further described in detail.

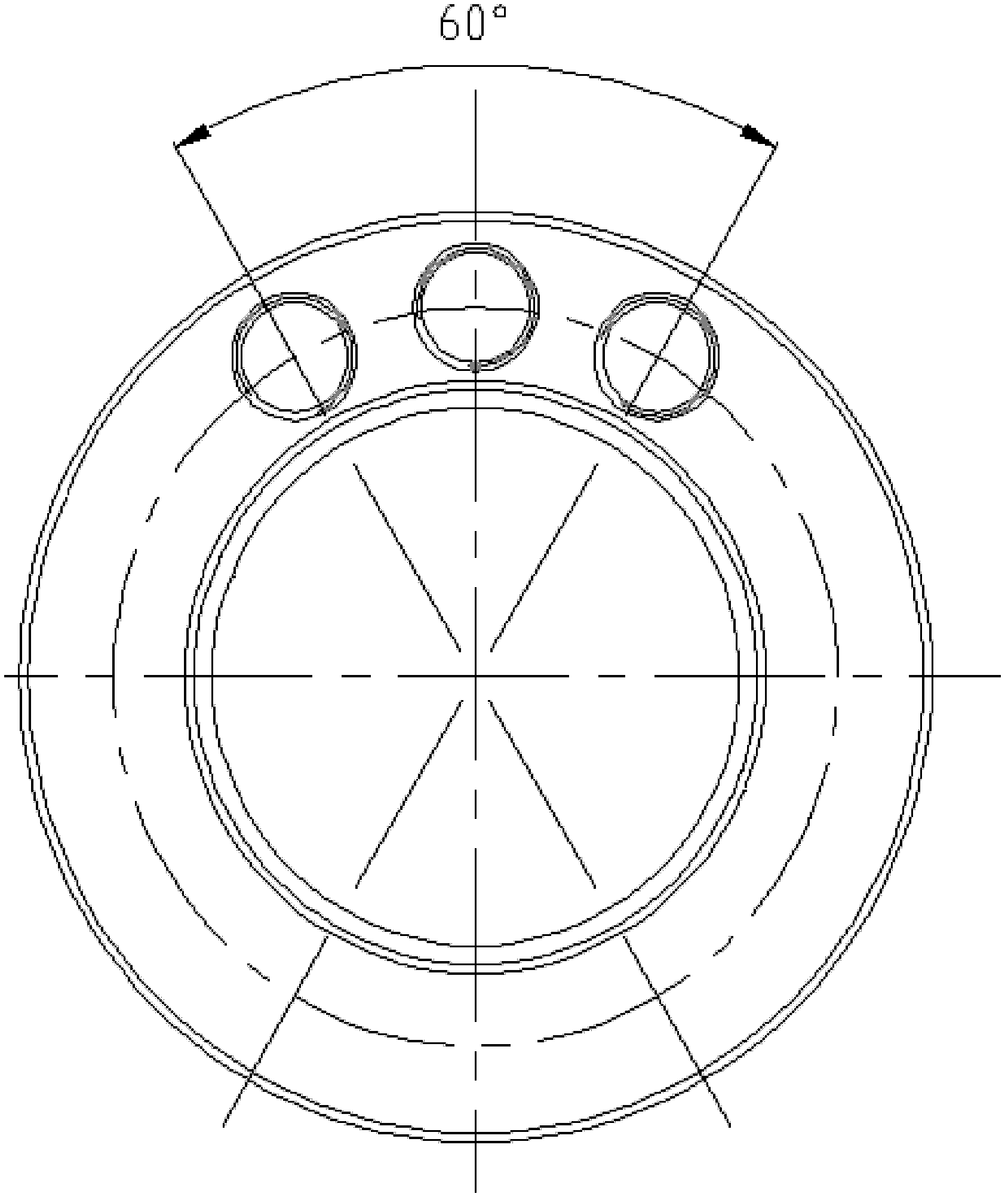

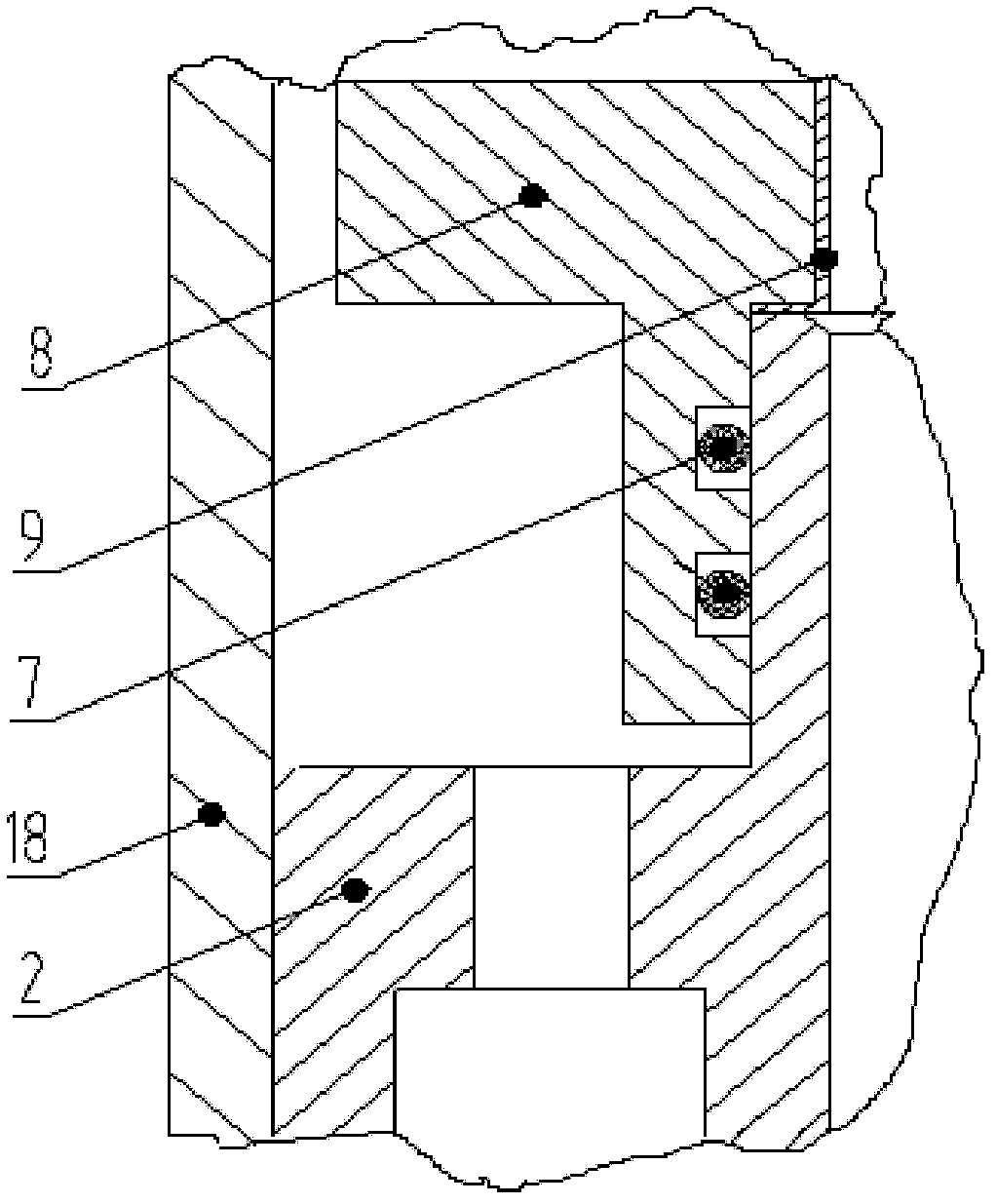

[0020] refer to figure 1 . The stator of the downhole cylindrical linear motor of the present invention is mainly composed of a lower limit retaining ring 1, a dynamic pressure sealing body 2, a dynamic pressure piston retaining ring 3, a dynamic pressure piston 4, a dynamic pressure piston sealing ring 5, and a dynamic pressure sealing body sealing ring 6 , lower plug sealing ring 7, lower plug 8, stator inner sleeve 9, stator coil 10, stator silicon steel sheet 11, upper plug 12, upper plug sealing ring 13, stator lead wire assembly 14, stator upper sealing body 15. The stator upper sealing body seal ring 16, the upper limit retaining ring 17 and the stator shell 18 are composed.

[0021] The stator housing 18 is in the shape of a circular tube. The inner diameter of the stator ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com