Multilayer bevel-plate sedimentation device with variable interval and variable flow direction

A technology of slanting plate sedimentation and variable spacing, which is applied in the direction of the settling tank, etc., can solve the problems of micro floc particle leakage, inclined plate clogging, etc., and achieve the effect of smooth sludge discharge, no clogging of sludge discharge, and high sedimentation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

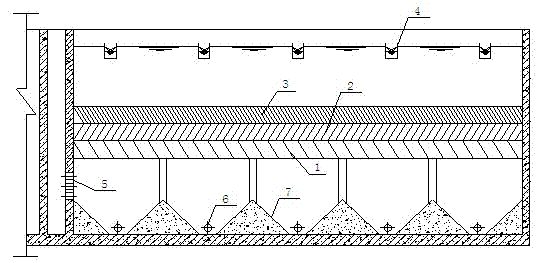

[0015] As shown in the accompanying drawings, the utility model is composed of 3 or more layers of sloping plate components with variable spacing. The included angle between the sloping plate assembly and the horizontal plane is 60 degrees, and the sloping plate assemblies on two adjacent floors are arranged in opposite directions. The water flow passes through each layer of sloping plate assemblies sequentially from bottom to top, and constantly changes the flow direction. The high concentration of floc particles in the bottom sloping plate of the water flow can form an active sludge layer, and when the floc particles pass through this layer, they can be trapped by contact flocculation. Larger floc particles will be removed in the bottom and middle sloping plate components, as the water flow through the sloping plate area changes its flow direction from bottom to top, tiny floc particles will deviate from the streamline under the action of inertia and be trapped by the slopin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com