A method for treating polluted acid wastewater with modified red mud powder

A technology for polluted acid wastewater and red mud, which is applied in water/sludge/sewage treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc. Land and other issues, to achieve the effects of low raw material prices, easy reuse, and low processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

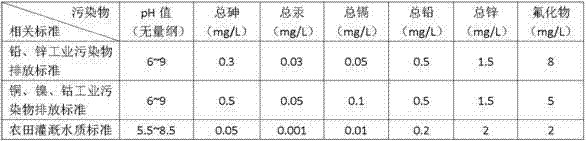

[0024] Take 5000mL of polluted acid wastewater produced in the process of lead smelting and put it in a plastic bucket. After 24 hours of static precipitation, take the supernatant for testing. The test results: pH is 0.65, arsenic is 26.5 mg / L, mercury is 1.34 mg / L L, cadmium is 5.51 mg / L, lead is 11.6 mg / L, zinc is 47 mg / L, and fluoride ion is 759 mg / L. Take 200ml of the supernatant and put it in a 500ml Erlenmeyer flask, neutralize it with milk of lime to pH 7.0, precipitate to remove some harmful substances such as arsenic, cadmium, lead, zinc and fluorine, and then add 1.5g of modified red mud powder, Stirring at 180r / min at 30°C for 2.5 hours, sedimentation for 30 minutes and centrifugation, the pH value of the water was 7.6, and the concentrations of arsenic, mercury, cadmium, lead, zinc and fluorine were 0.21 mg / L, 0.02 mg / L, 0.03 mg / L, respectively. L, 0.28 mg / L, 1.24 mg / L and 7.45 mg / L, which are lower than the discharge concentration limit of water pollutants for ne...

Embodiment 2

[0026] Get 5000mL of dirty acid waste water produced in the lead smelting process and place it in a plastic bucket, let it settle for 24 hours, get the supernatant and test it, the test result is the same as in Example 1. Take 200ml of the supernatant and put it in a 500ml Erlenmeyer flask, neutralize it with milk of lime to pH 7.0, precipitate to remove some harmful substances such as arsenic, cadmium, lead, zinc and fluorine, and then add 2.6g of modified red mud powder, Stirring at 180r / min at 30°C for 2.5 hours, sedimentation for 60min and centrifugation, the pH value of the water was 7.9, and the concentrations of arsenic, mercury, cadmium, lead, zinc and fluorine were 0.035mg / L, 0.0007mg / L and 0.006mg / L respectively. L, 0.12mg / L, 0.28mg / L and 1.6mg / L, which are lower than the most stringent standard values of GB 5084-2005 control items in Table 1. After the sewage acid wastewater is treated by the lime neutralization method, the total hardness (calculated as calcium ca...

Embodiment 3

[0028]Take 5000mL of polluted acid waste water produced in the process of copper smelting, put it in a plastic bucket, let it settle for 24 hours, and take the supernatant for testing. The test results: pH is 0.76, arsenic is 31.2 mg / L, mercury is 0.83 mg / L L, cadmium is 4.36mg / L, lead is 7.5mg / L, zinc is 27.4mg / L, and fluoride ion is 587mg / L. Take 200ml of the supernatant and put it in a 500ml Erlenmeyer flask, neutralize it with milk of lime to pH 7.0, precipitate to remove some harmful substances such as arsenic, cadmium, lead, zinc and fluorine, and then add 1.4g of modified red mud powder, Stirring at 180r / min at 30°C for 2.5 hours, sedimentation for 30 minutes and centrifugation, the pH value of the water was 7.5, and the concentrations of arsenic, mercury, cadmium, lead, zinc and fluorine were 0.32mg / L, 0.02mg / L, 0.03mg / L respectively L, 0.23mg / L, 0.76mg / L and 4.16mg / L, which are lower than the concentration limit of water pollutants discharged by new enterprises in GB ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com