Method for resource recycling treatment on produced water of high-sulfur gas field

A gas field produced water and treatment technology technology, which is applied in mining wastewater treatment, water treatment parameter control, chemical instruments and methods, etc. Poor injection ability, no longer suitable for environmental protection requirements, etc., to achieve the effect of high quality, strong adaptability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

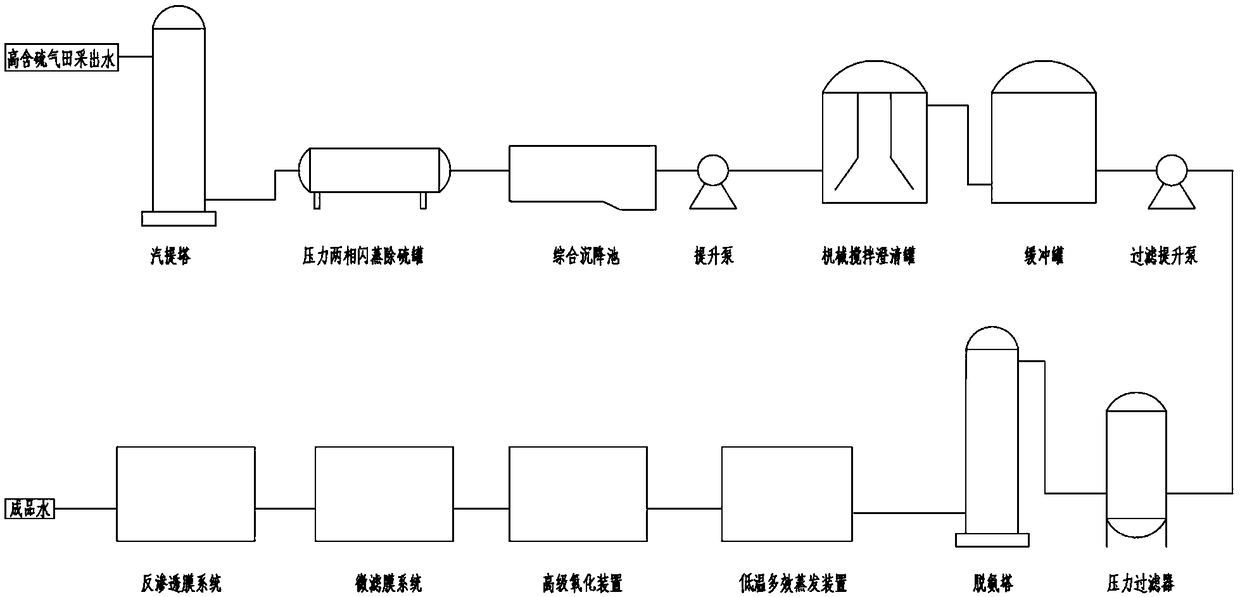

[0041] A treatment process for produced water from high-sulfur gas fields, comprising the following specific steps:

[0042] Step 1: Carry out closed desulfurization treatment on the produced water of high-sulfur gas fields, and remove sulfides in the produced water through the stripping step, depressurization flash step and oxidation step to ensure that the sulfide content in the produced water is ≤5mg / L ;

[0043] Step 2: The produced water treated in the first step is clarified and filtered by mechanical agitation to remove calcium, magnesium, strontium and other scaling ions in the water, so as to ensure that the average content of scaling ions in the produced water after treatment is ≤15mg / L;

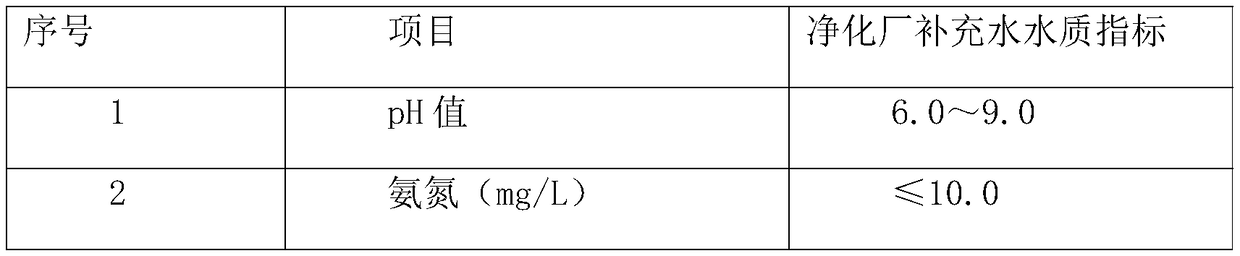

[0044] The third step: Pre-evaporate the produced water after the second step to remove the ammonia nitrogen in the produced water. The ammonia nitrogen content in the influent water is ≤150mg / L to ensure that the ammonia nitrogen content in the produced water is ≤10mg / L;

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com