Quick filter cake removing and filter cloth washing device for filter press

A technology of filter press and filter cloth, which is applied in the fields of filtration and separation, chemical instruments and methods, and separation methods, and can solve the problems of slow cake unloading speed, complex structure, and production impact of the filter press.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

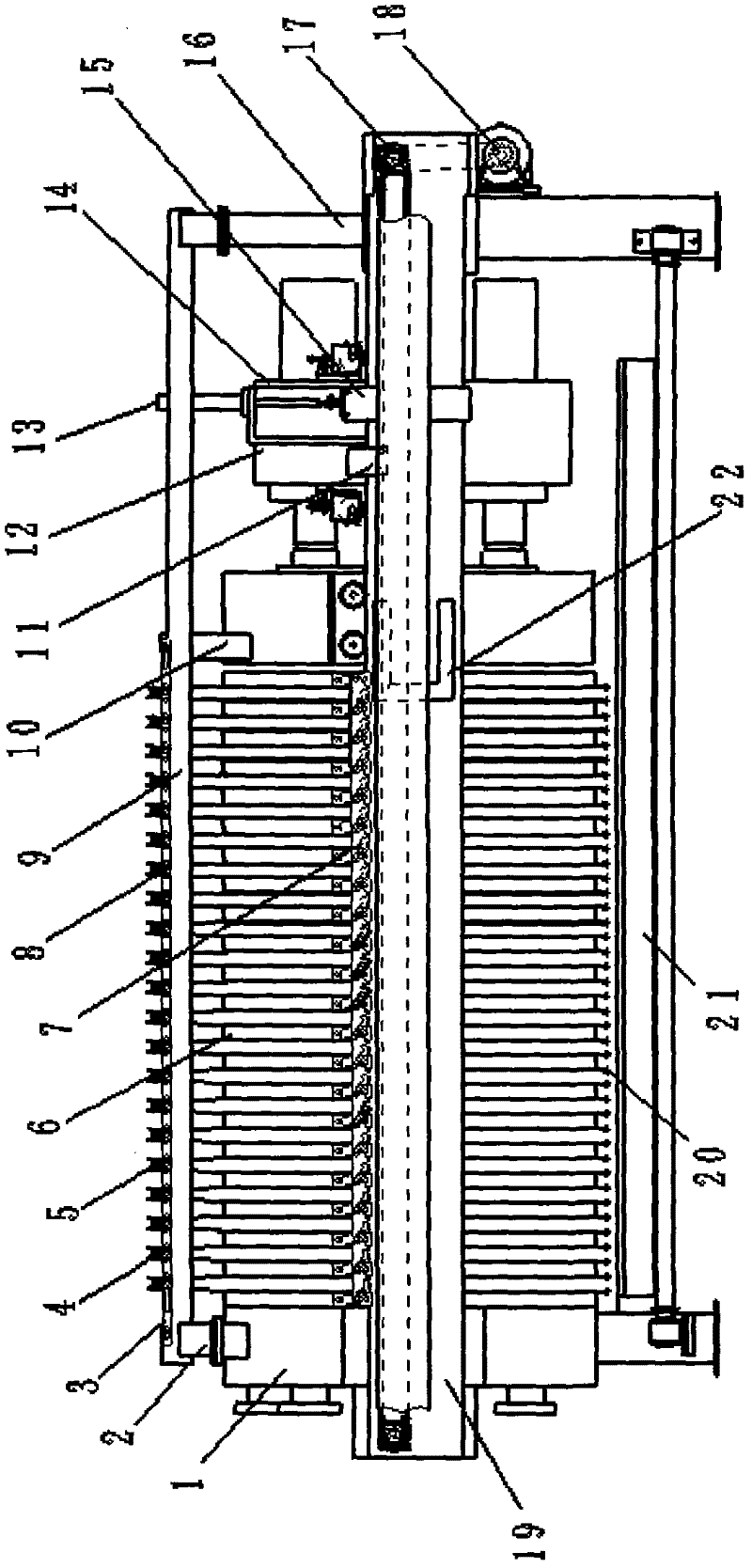

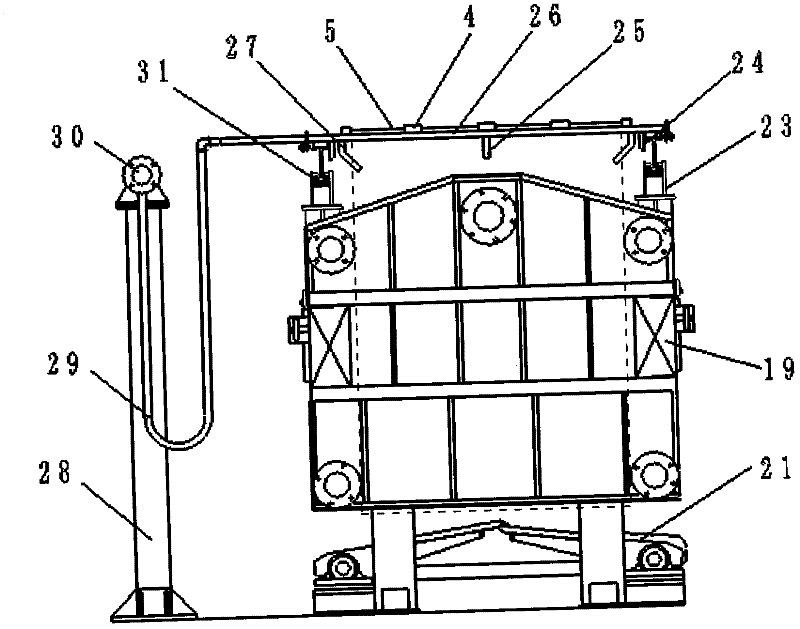

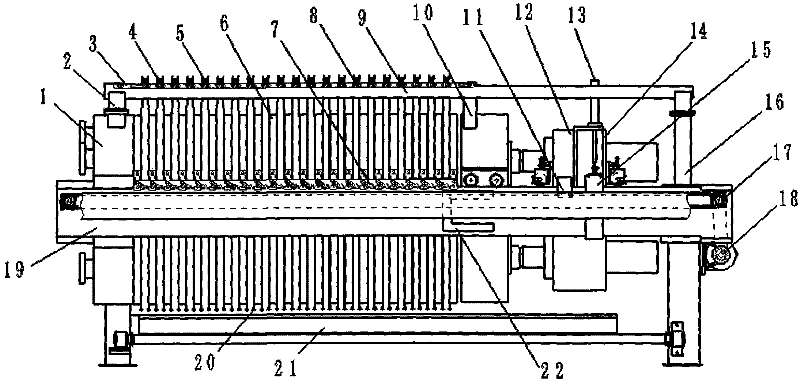

[0016] see figure 1 and figure 2 As shown, a filter press quick unloading and filter cloth cleaning device provided by the present invention is provided with a movable cylinder base 12 connected to a pressing plate, pulleys are arranged on both sides of the movable cylinder base 12 and installed on the upper end of the main beam 19, and the movable cylinder base 12 Connecting plate 11 is arranged on both sides to be equipped with pin shaft connection chain, is provided with decelerating motor 18 and is installed sprocket wheel and chain, is provided with driving shaft and is installed with sprocket wheel, and driving shaft two ends are provided with driving sprocket 17 and chain and are installed on main girder 19 sides, The connecting plate 11 and the passive sprocket of the mobile cylinder base 12 are connected by a chain. The driving sprocket 17, the passive sprocket and the chain are installed on the side of the main beam. The lifting bracket 14 is arranged on both sides ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com