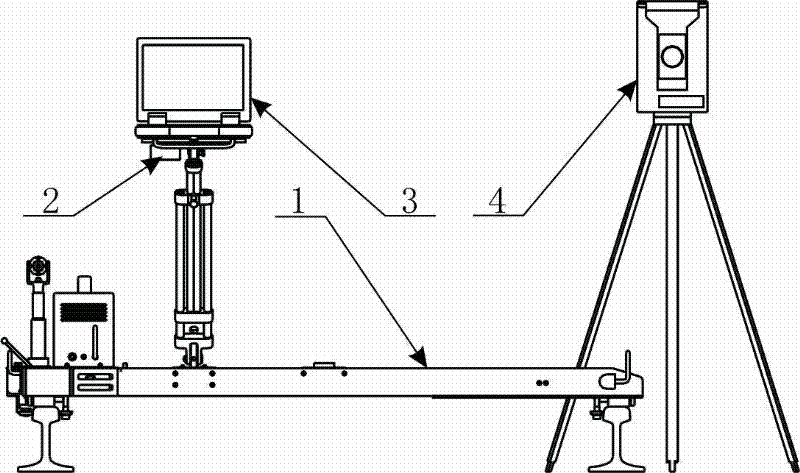

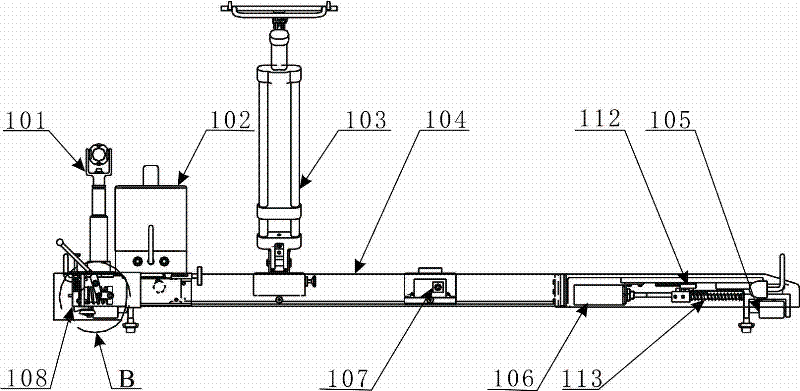

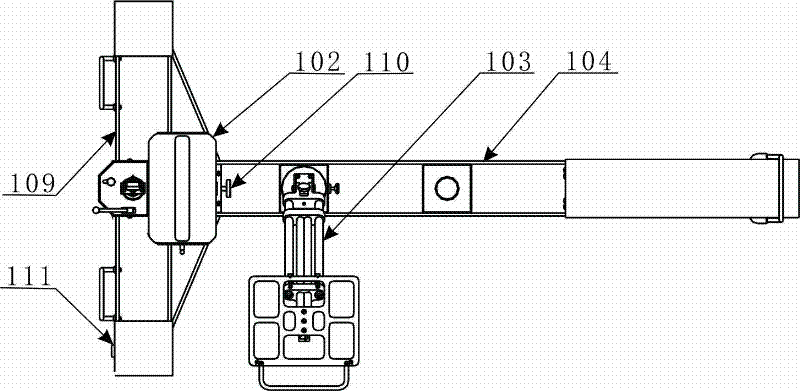

Detection method for restrictedly measuring track parameters and track checking instrument

A technology for track parameters and detection methods, which is applied to measurement devices, railway vehicle shape measuring instruments, instruments, etc., can solve problems such as the need to improve the accuracy, the limitation, and the inability to meet the on-site detection requirements of high-speed railways and existing speed-increasing lines. The effect of improving work efficiency, stable device performance and improving test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] The on-site measurement was carried out in the K46+15.951-K46+635.286 section of the Dujiangyan right branch line of the Chengguan High-speed Railway. The total length of the measured track is 620 meters (including straight lines, transitional curves and circular curves), divided into 3 sections, within a distance of 200-210 meters Continuous dynamic measurement, the continuous dynamic measurement sampling interval is 0.2083 meters, a total of 4 round trips are measured, of which the fourth round trip turns the track inspection trolley around 180°, and the measurement takes 35 minutes for a single pass. In the measured data, 152 points were selected at an interval of about 4 meters for analysis and the results are as follows:

[0069] Measuring repeatability:

[0070] Gauge: The measurement repeatability within the extreme difference of 0.45mm is 96.78%;

[0071] Level: the measurement repeatability within 0.45mm of the extreme difference is 95.82%;

[0072] Centerlin...

Embodiment 2

[0080] The on-site measurement was carried out again in the K46+15.951-K46+635.286 section of the Dujiangyan right branch line of the Chengguan High-speed Railway. The total length of the measured track is 620 meters, which is divided into 5 sections. The continuous dynamic measurement distance of each section is controlled between 120 and 130 meters. The sampling interval of the continuous dynamic measurement is 0.2083 meters, a total of 4 round trips are measured, and the fourth round trip is measured after the car is turned around. The single measurement time is 50 minutes. The selected point analysis results in the measured data are as follows in embodiment 1:

[0081] Measuring repeatability:

[0082] Gauge: The measurement repeatability within the range of 0.45mm is 96.85%;

[0083] Level: the measurement repeatability within 0.45mm of the extreme difference is 95.82%;

[0084] Centerline lateral deviation: measurement repeatability within 3mm of extreme difference is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com