Movable automatic power charging and switching station as well as cell rapid replacement method for electric automobile

A technology for electric vehicles and charging and swapping stations, which is applied to electric vehicles, charging stations, motor vehicles, etc., can solve the problems of wasting energy, large floor space, and long construction period, and achieves the advantages of popularization and application, automatic and fast loading and unloading, Small investment in construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Below in conjunction with specific embodiment the present invention is described in further detail:

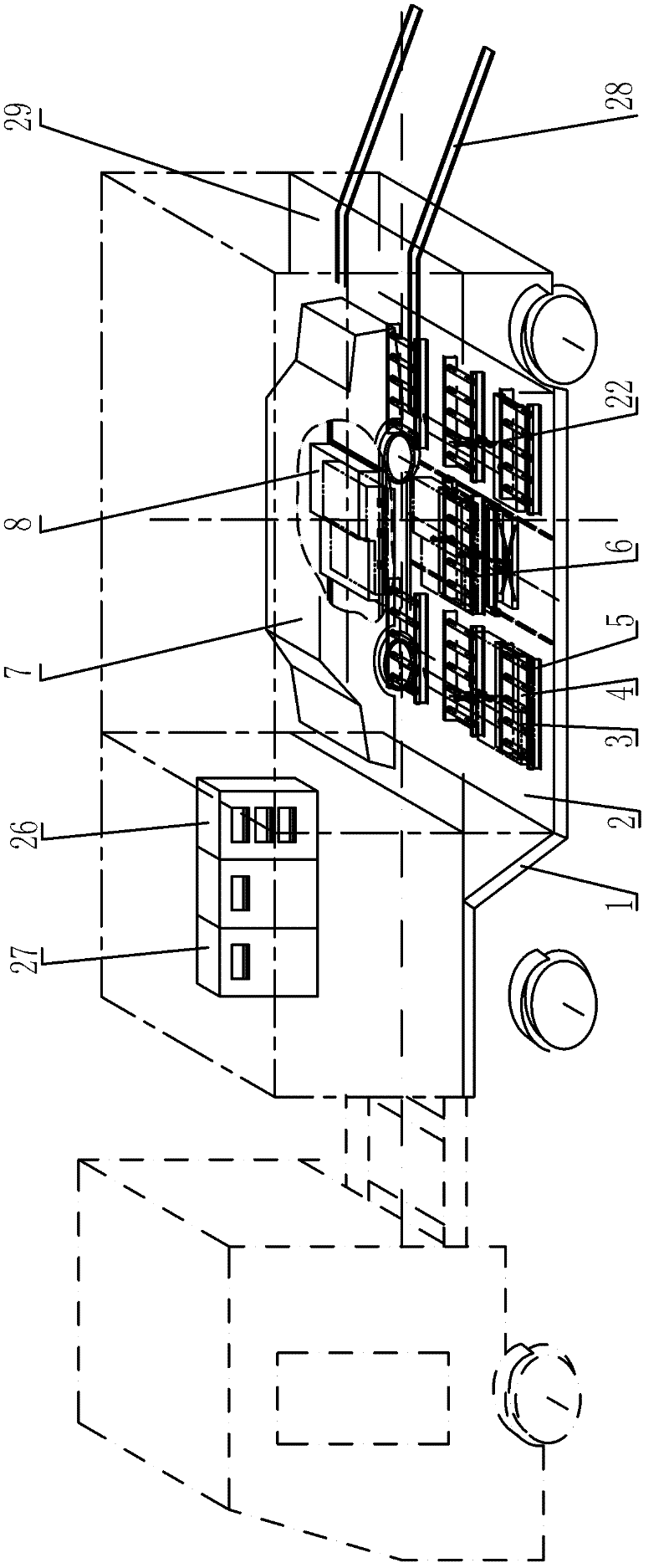

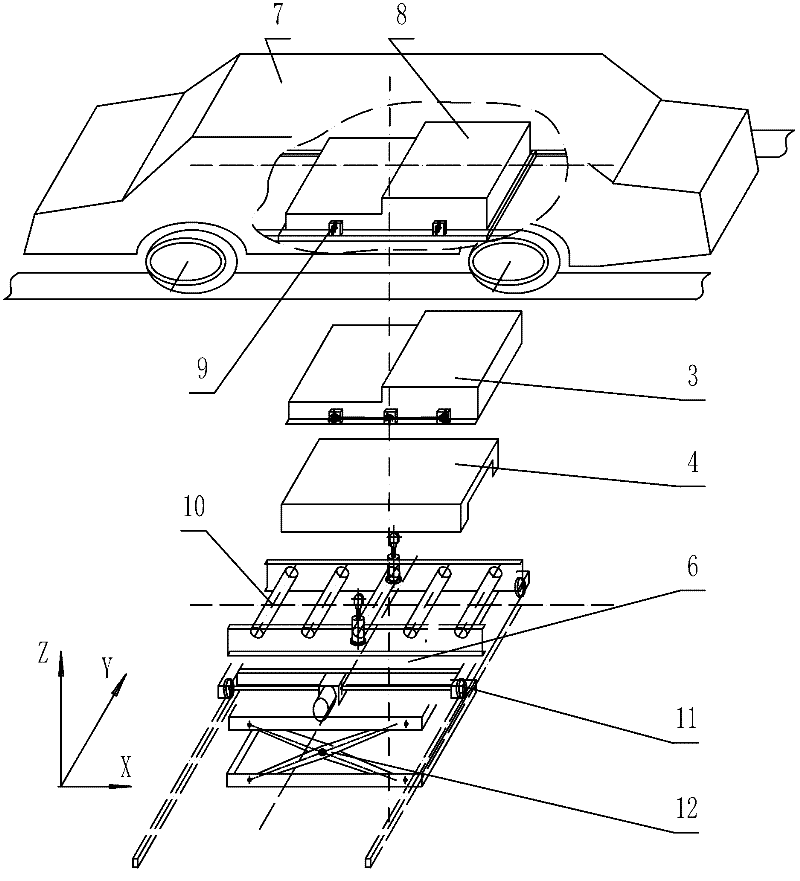

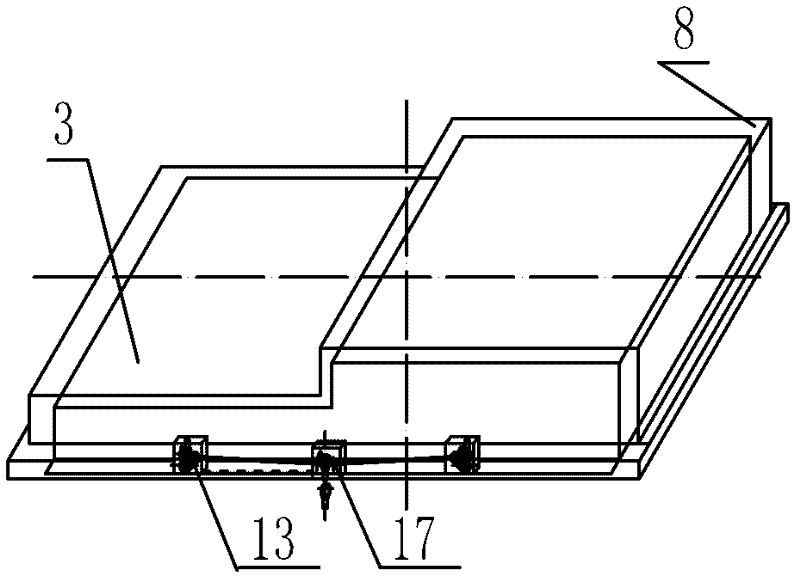

[0047] Such as figure 1 As shown, a mobile automatic charging and changing station for electric vehicles in the present invention includes: a box-type semi-trailer 1, a battery box 3, a battery box bracket 4, an automatic battery changing device 6, a battery compartment 8, an unlocking / locking push Rod mechanism 20, charger 26 and control cabinet 27. The box-type semi-trailer 1 is provided with a battery storage warehouse 2, a plurality of battery boxes 3, an automatic battery exchange device 6, an automatic charging system and an automatic control system; Trailer, the rear part of which opens the door, and is pulled and moved by the tractor head; the chassis of the box-type semi-trailer 1 is a double-layer structure, and the upper platform 29 is provided with vehicle guide rails 28, and the space between the upper platform and the floor forms the space between the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com