Eccentric star-like cinder valve

An eccentric, ash unloading valve technology, applied in the direction of loading/unloading, rotary conveyors, conveyors, etc., can solve the problems of poor application effect, reduced ash unloading or feeding capacity, uneven unloading, etc. Achieve remarkable energy-saving effect, low manufacturing cost and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

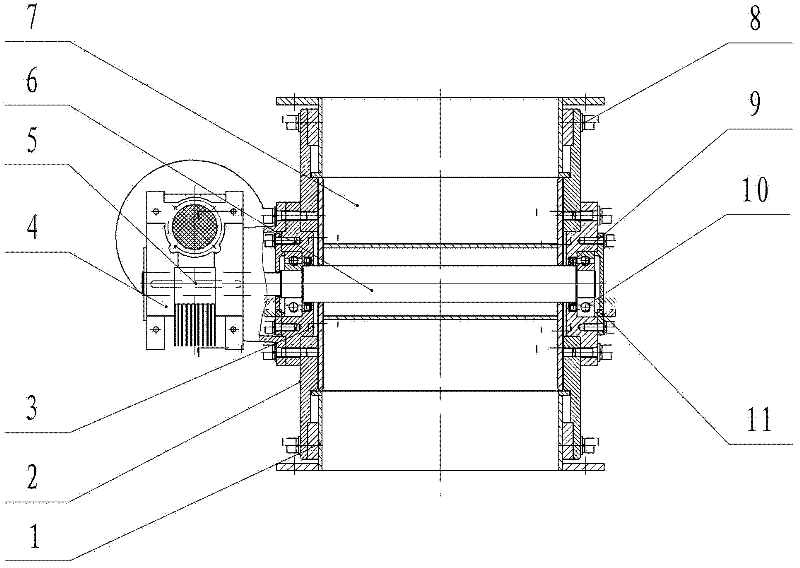

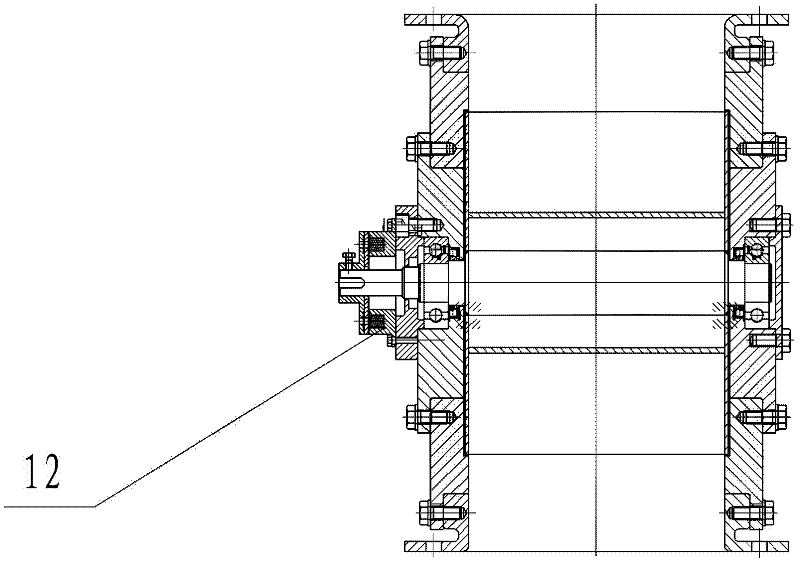

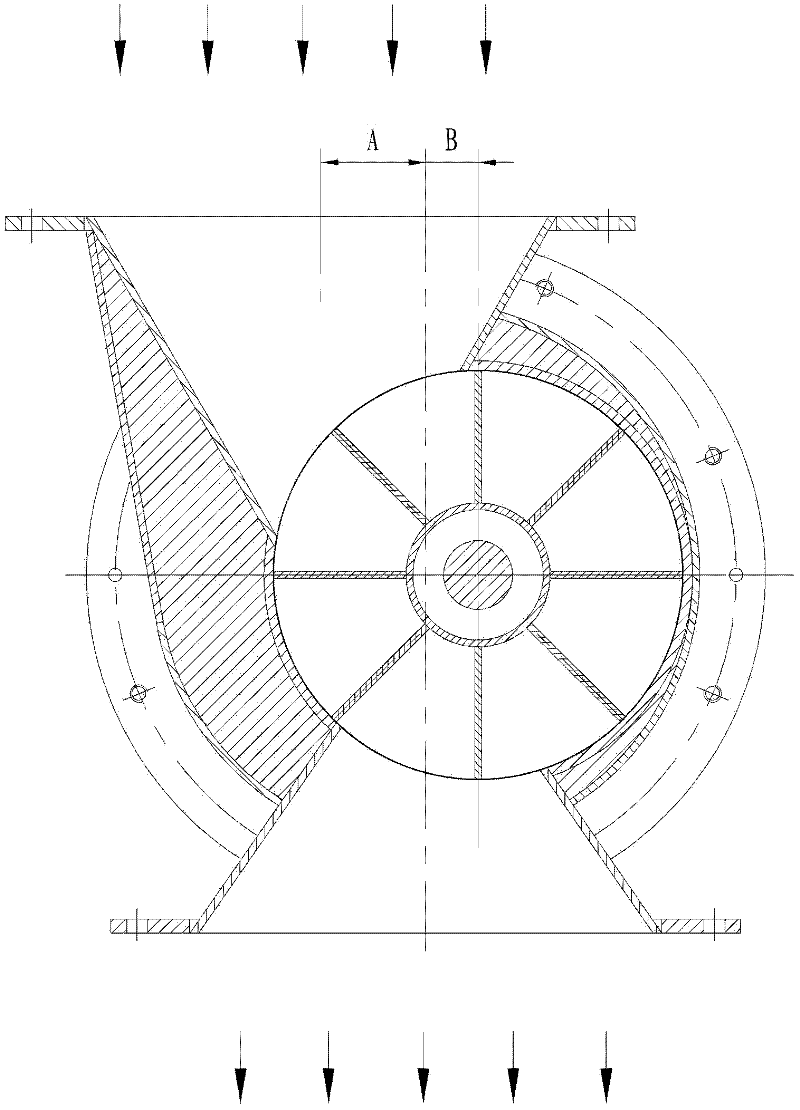

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0024]The valve casing of the present invention is an eccentric structure similar to a volute, and the inner cavity is two cylindrical surfaces of different sizes. After boring processing, it reaches a certain degree of smoothness and matching precision. Both the inner cavity and the outer surface of the shell are incomplete cylindrical surfaces with openings at the top and bottom, the upper opening is connected with the feeding port, and the lower part is connected with the feeding port. The cylindrical surface of the inner cavity coincides with the rotation center of the impeller, but deviates from the geometric center of the valve, also deviates from the center of the large cylindrical surface, and also deviates from the center of the feed inlet. There can be a solid structure or a thin-walled structure between the inner and outer cylindri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com