Silver-separating apparatus of silver-containing anode slime

The technology of separating equipment and silver anode slime is applied in the field of wet smelting equipment for precious metals, which can solve the problems of acid mist leakage, polluting the environment, affecting system sealing, large power consumption, etc., and achieving a good operating environment, high separation efficiency, and structural simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

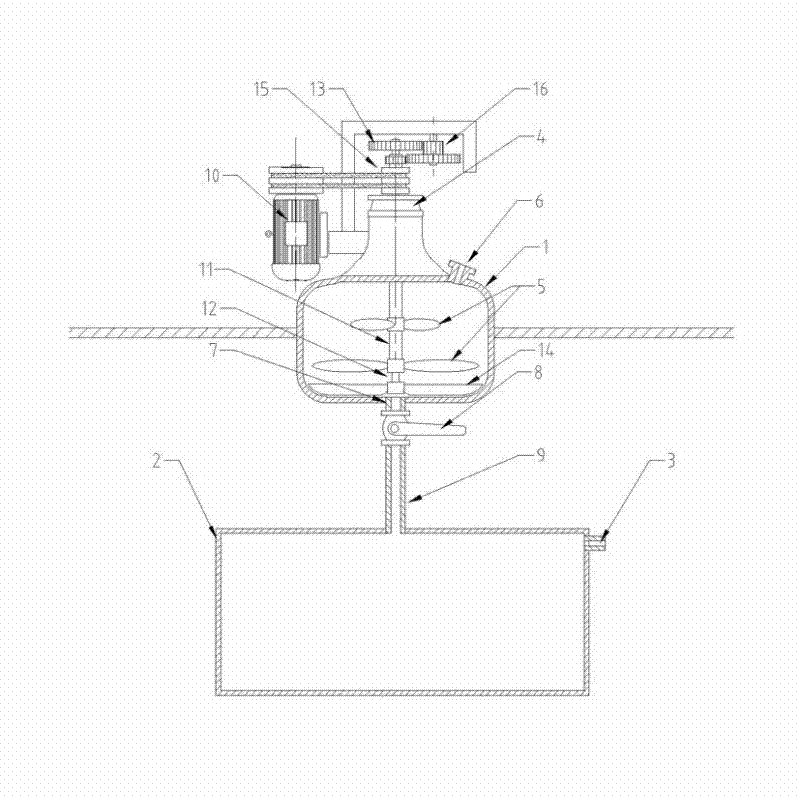

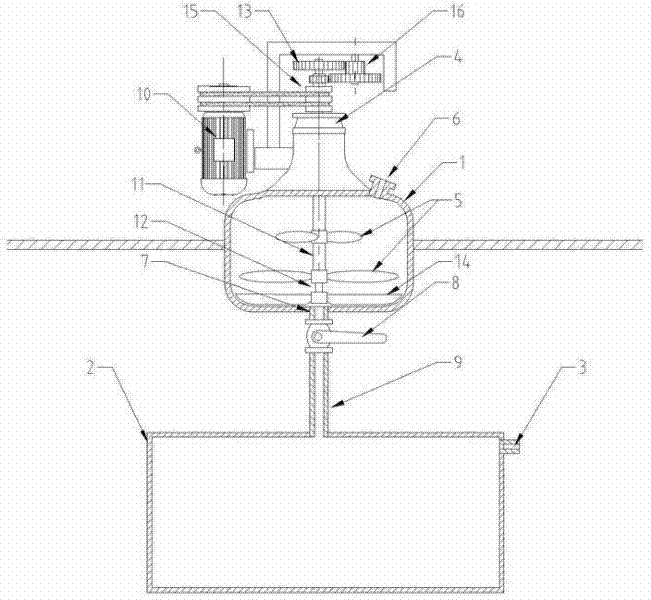

[0012] like figure 1 As shown, a silver separation equipment for silver-containing anode slime , It consists of a reaction vessel 1 and a separation barrel 2; the reaction vessel 1 is a sealed glass fiber reinforced plastic tank, the lowest part of which is in the shape of a spherical crown, and is higher than the highest part of the separation barrel 2; the upper side of the separation barrel 2 has an overflow port 3; The double-layer stirring paddle 5 on the agitator 4 extends into the container from directly above the reaction vessel 1; the agitator main shaft 11 is a hollow shaft, and a long mandrel 12 is set inside the shaft, and the upper end of the long mandrel exceeds the part of the agitator main shaft 11 Connect the large driven gear 13; the part of the lower end of the long mandrel that exceeds the agitator main shaft 11 is connected to the scraper 14; the agitator main shaft 11 is terminated with a pulley 15 with a driving pinion, and the pulley is connected by a m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com