High temperature resistant oxyferrite heat resistant steel bar and preparation process thereof

A ferrite oxide, heat-resistant steel technology, applied in machinery, heat-resistant steel bars, energy, metallurgy, chemical industry, can solve the problems of high Cr content, Cr volatilization, application restrictions, etc., to achieve good oxidation resistance, The effect of high purity

Inactive Publication Date: 2012-03-28

CENT IRON & STEEL RES INST

View PDF2 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the Cr content in Crofer22 heat-resistant steel is relatively high, and a small amount of Cr will volatilize at high temperature and produce toxic gas, which limits its further application.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0013] The present invention will be further described below in conjunction with a typical embodiment.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

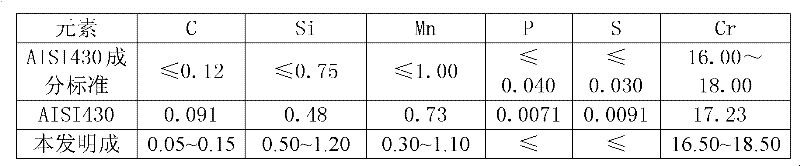

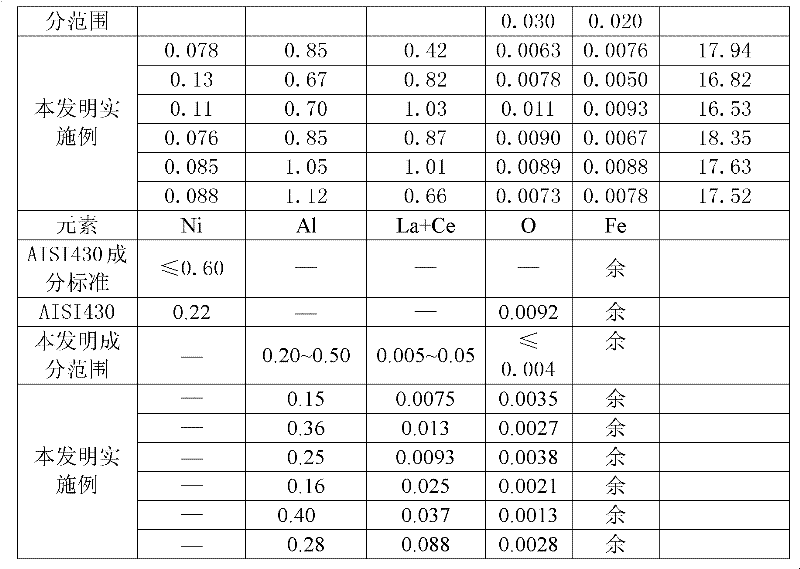

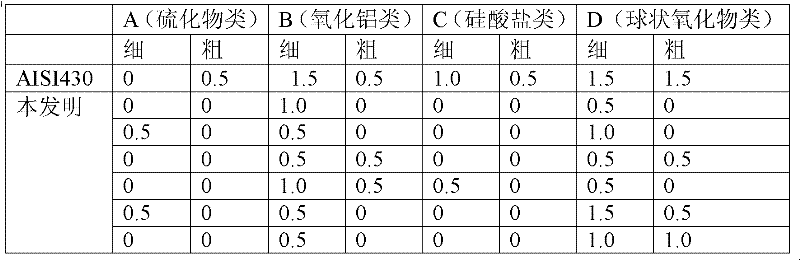

The invention which relates to a high temperature resistant oxyferrite heat resistant steel bar and a preparation process thereof belongs to the technical field of heat resistant steel bars. The bar which is smelted by a vacuum induction furnace comprises the following chemical components, by weight, 0.05-0.15% of C, 0.50-1.20% of Si, 0.30-1.10% of Mn, equal to or less than 0.030% of P, equal to or less than 0.020% of S, 16.50-18.50% of Cr, 0.20-0.50% of Al, 0.005-0.05% of (La+Ce), and the balance Fe and inevitable impurities, wherein the oxygen content is not more than 40ppm. The process comprises steps of vacuum smelting and forging, wherein technical parameters in the process are that the steel ingot cogging temperature is 1155-1175DEG C, the initial forging temperature is 1140-1160DEGC, the final forging temperature is 880-920DEG C, and the bar is air-cooled after forging. The bar of the invention has the advantages of less impurity, high strength and good oxidation resistance.

Description

technical field [0001] The invention belongs to the technical field of heat-resistant steel rods, in particular to a high-temperature oxidation-resistant ferrite heat-resistant steel rod and a preparation method thereof, which are mainly applicable to the fields of metallurgy, energy, machinery, chemical industry and the like. Background technique [0002] With the development of steam boilers, power stations, gas turbines and aero-engines, in order to meet the needs of various components working at higher temperatures, metallurgical material workers have developed a series of low-carbon steels with high thermal strength and oxidation resistance. performance heat-resistant steel. These heat-resistant steels can be classified into pearlitic heat-resistant steels, martensitic heat-resistant steels, austenitic heat-resistant steels, ferritic heat-resistant steels, and precipitation hardening heat-resistant steels according to their structures. Pearlitic heat-resistant steel us...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22C38/18B21J5/00

Inventor 王立民刘正东杨钢包汉生李密

Owner CENT IRON & STEEL RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com