Unilateral-ribbing anti-seismic reinforcing method for existing brickwork structure

A technology of masonry structure and reinforcement, which is applied in the direction of earthquake resistance, building components, building structure, etc., to achieve the effect of improving seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

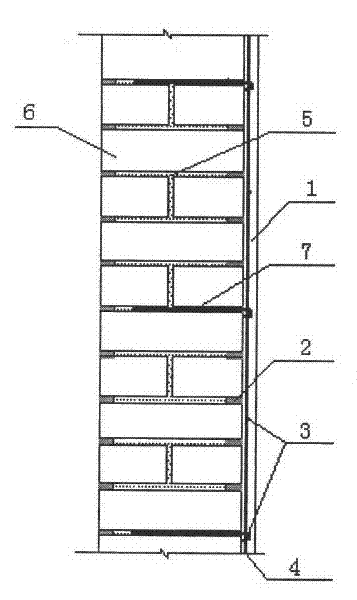

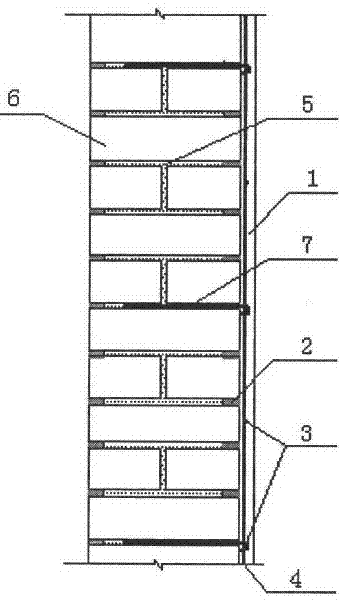

[0013] The core principle of the present invention is: by adding reinforcement mesh sheets on one side of the wall and connecting them with L-shaped wall-through steel bars, the steel bars and the wall form a whole, thereby improving the seismic performance of the wall.

[0014] Such as figure 1 As shown, the existing single-side reinforced seismic reinforcement method of the masonry structure of the present invention, the main steps are as follows:

[0015] 1) After the original wall is cleaned, the mortar joints 5 between the wall blocks 6 on both sides are re-pointed, the depth of each side is ≥30mm, and the strength of the caulking mortar is M10.

[0016] 2) Make φ6300 (vertical arrangement of steel bars 3) × 150 (horizontal arrangement of steel bars 4) welded steel mesh pieces on one side of the wall.

[0017] φ6300×150 means: the steel bar diameter of the steel mesh sheet is 6mm, the vertically arranged steel bar spacing is 300mm, and the horizontally arranged steel bar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com