Continuous heat insulating oil pipe and manufacturing method thereof

A technology for insulating oil pipes and a manufacturing method, which is applied to drilling pipes, casings, earth-moving drilling, etc., can solve problems such as affecting operation efficiency, long operation period, failure of joints, etc. The method is simple and easy to implement, and the effect of avoiding the loss of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

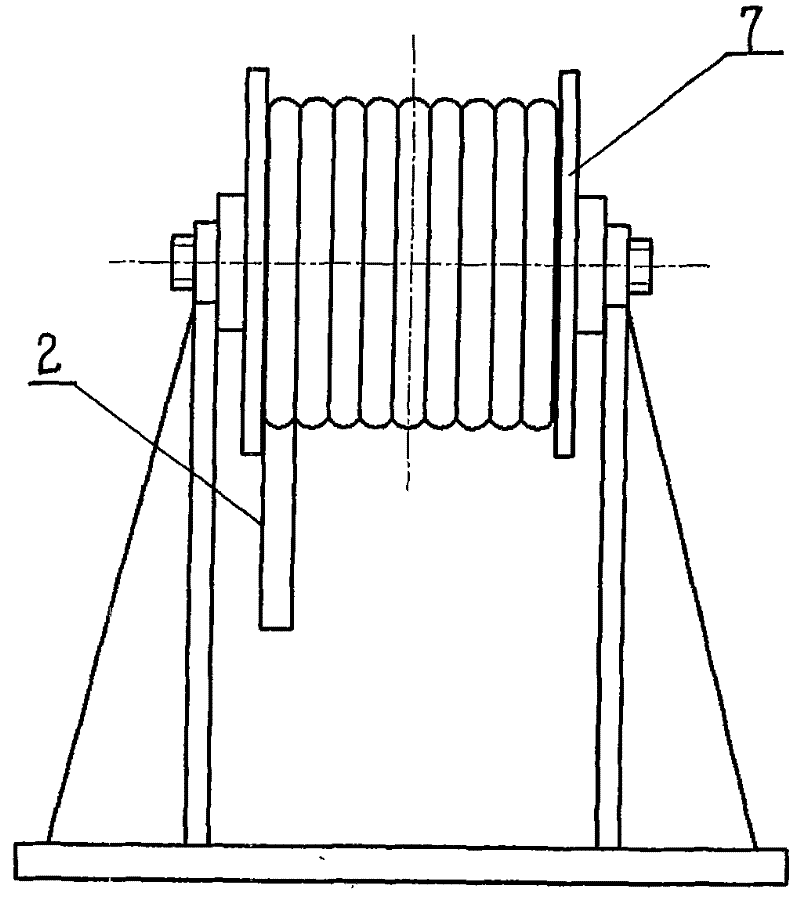

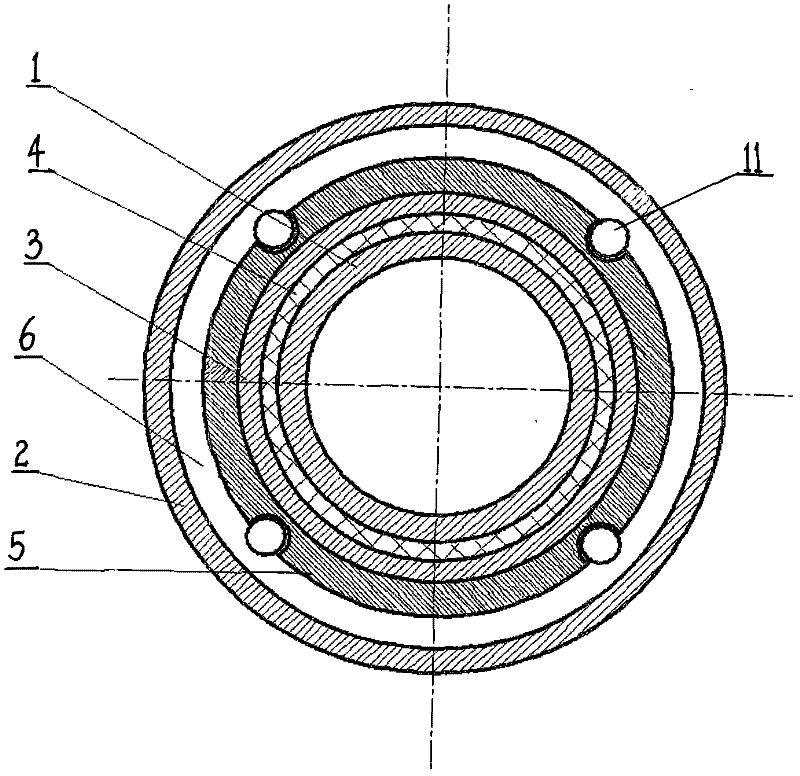

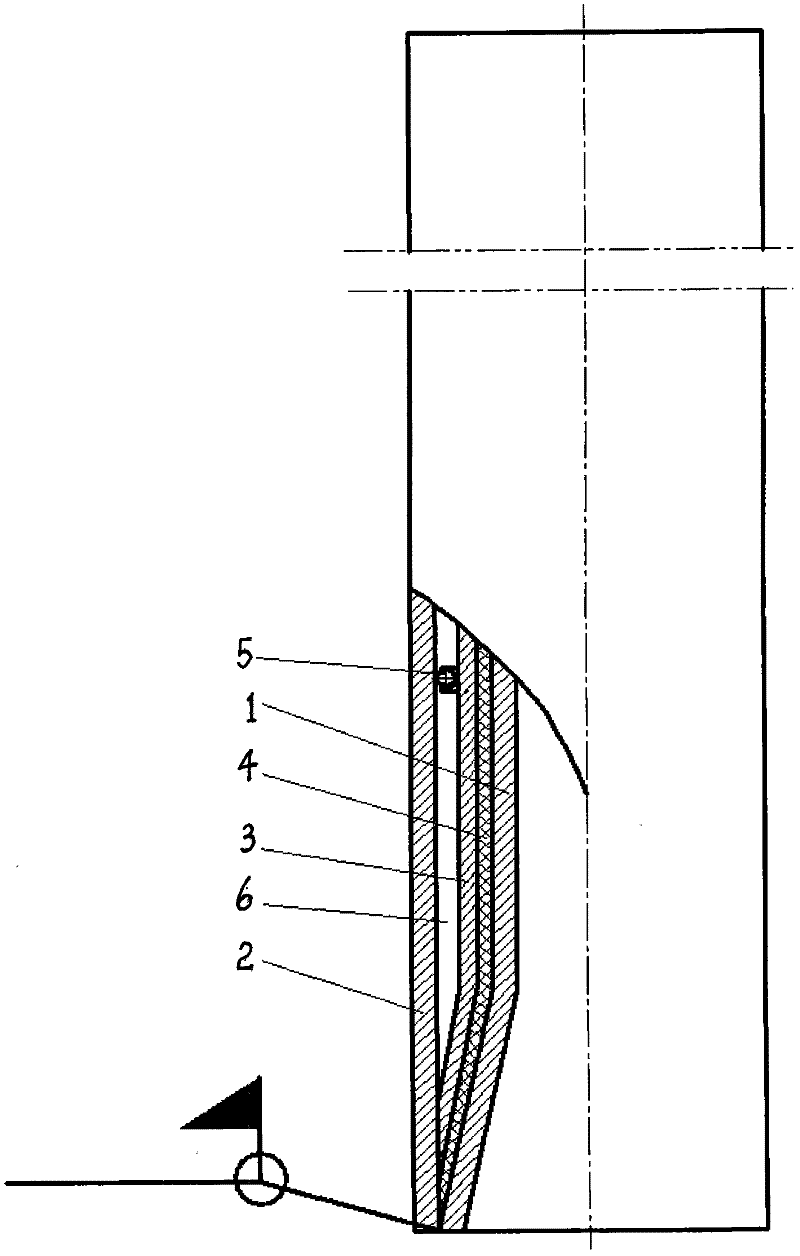

[0029] combined with figure 1 , 2 , 3, 4 describe an embodiment of the present invention.

[0030] A continuous heat-insulating oil pipe includes an inner pipe 1, an outer pipe 2 and a heat-insulation layer 3. The inner pipe 1 and the outer pipe 2 are the whole coiled tubing, and the outer wall of the inner pipe 1 is sprayed with a heat-reflective and heat-insulating coating 4, and the heat-reflecting and heat-insulating coating 4 is wrapped with a heat-insulating layer 3; The outer tube 2 is set on the inner tube 1 and can be wound on the reel III 7, and a positioning ring 5 is installed on the outer wall of the inner tube 1 at an interval of 500-600mm, and a ball 11 is installed on the outer circle of the positioning ring 5, And the inner walls of the two ports of the outer tube 2 are respectively welded and sealed with the outer walls of the two ports of the inner tube 1 , so that an annular space 6 is formed between the inner tube 1 and the outer tube 2 .

[0031] The a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com