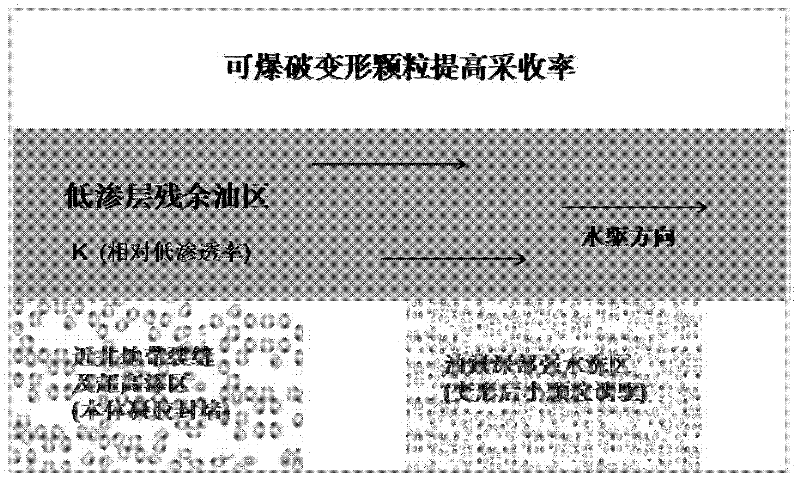

Method for improving oil field recovery rate

A recovery factor, oilfield technology, applied in chemical instruments and methods, production fluids, earthwork drilling, etc., can solve the problems of profile control, deep liquid flow diversion cannot be carried out synchronously, difficult on-site implementation, shear thinning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

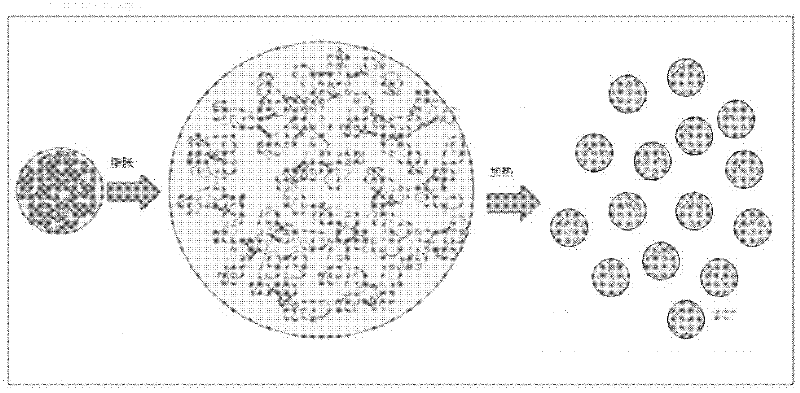

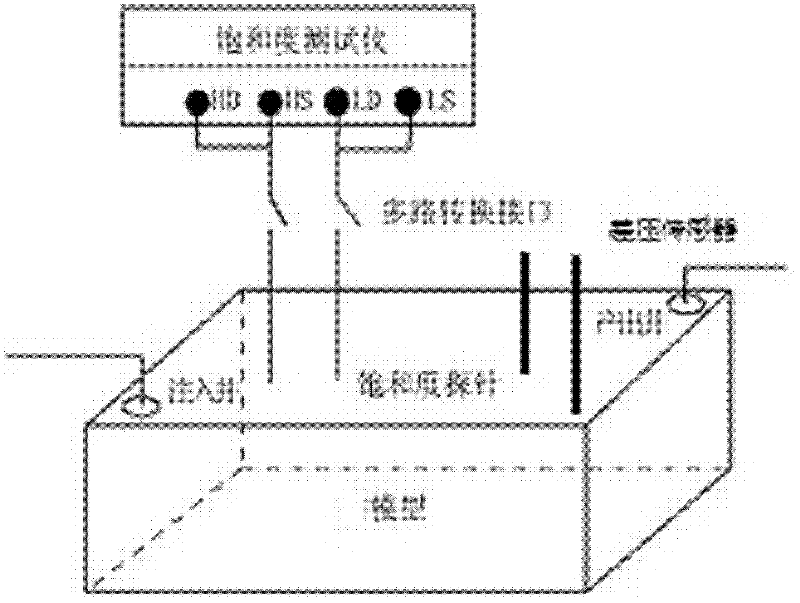

Method used

Image

Examples

Embodiment 1

[0082] This embodiment provides a pre-crosslinked gel particle for profile control and deep liquid flow diversion, which has the following raw material composition:

[0083]

[0084] Wherein, the ratio of the stable crosslinking agent to the monomer is 1:3000, and the ratio of the unstable crosslinking agent to the monomer is 1:300.

[0085] The pre-crosslinked gel particles for profile control and deep liquid flow diversion provided in this example were prepared according to the following steps:

[0086] Add 30 grams of acrylamide into 100 grams of distilled water to fully dissolve to obtain an acrylamide solution, which is the first monomer solution;

[0087] Add 1 g of methylene bisacrylamide into 100 g of distilled water and fully dissolve to obtain a methylene bisacrylamide solution, which is a stable crosslinking agent solution;

[0088] Add 1 g of methylenebisacrylamide solution into the acrylamide solution to obtain the first mixed solution;

[0089] Inject nitrogen...

Embodiment 2

[0107] This embodiment provides a pre-crosslinked gel particle for profile control and deep liquid flow diversion, which has the following raw material composition:

[0108]

[0109] Wherein, the ratio of the stable crosslinking agent to the monomer is 1:3000, and the ratio of the unstable crosslinking agent to the monomer is 1:300.

[0110] The preparation process of the pre-crosslinked gel particles for profile control and deep liquid flow diversion provided in this example can refer to Example 1, except for the amount of raw materials and additives, others are the same.

Embodiment 3

[0112] This embodiment provides a pre-crosslinked gel particle for profile control and deep liquid flow diversion, which has the following raw material composition:

[0113]

[0114] Wherein, the ratio of the stable crosslinking agent to the monomer is 1:3000, and the ratio of the unstable crosslinking agent to the monomer is 1:300.

[0115] The preparation process of the pre-crosslinked gel particles for profile control and deep liquid flow diversion provided in this example can refer to Example 1, except for the amount of raw materials and additives, others are the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com