Pressurizing dust remover of gasoline engine

A technology for dust collectors and gasoline engines, which is applied to machines/engines, mechanical equipment, engine components, etc., and can solve problems such as fuel increase, temperature engine performance wear, displacement power, and functions that do not meet design requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

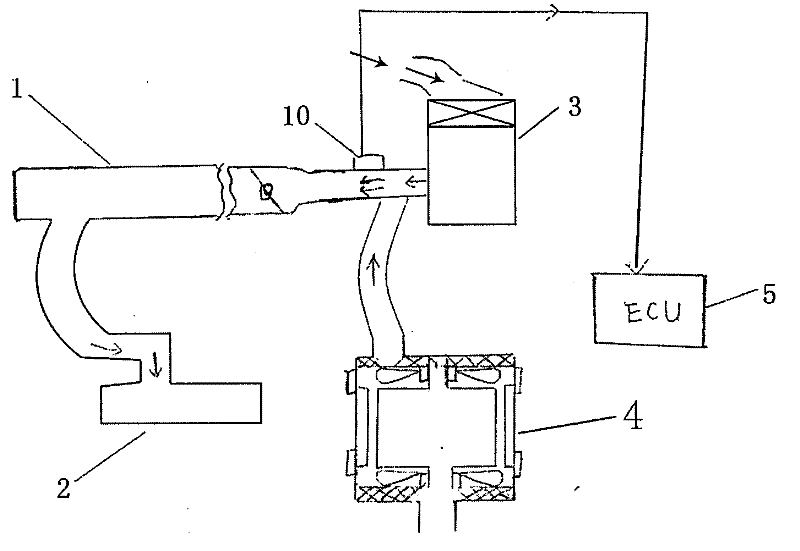

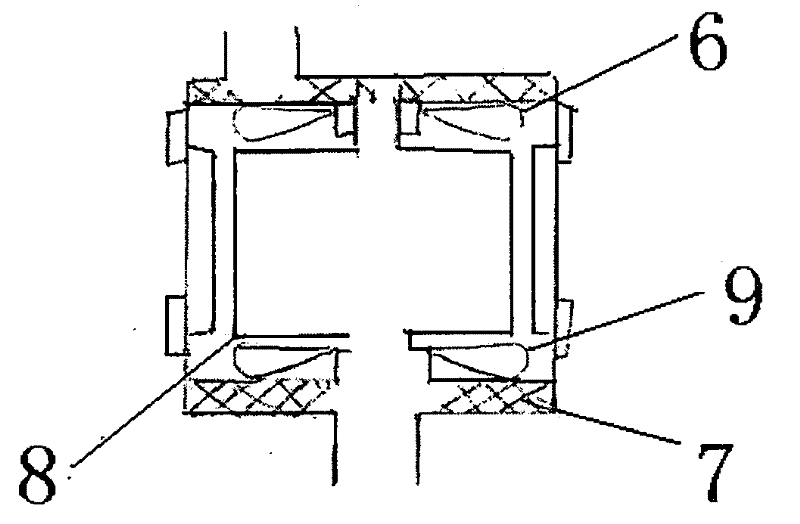

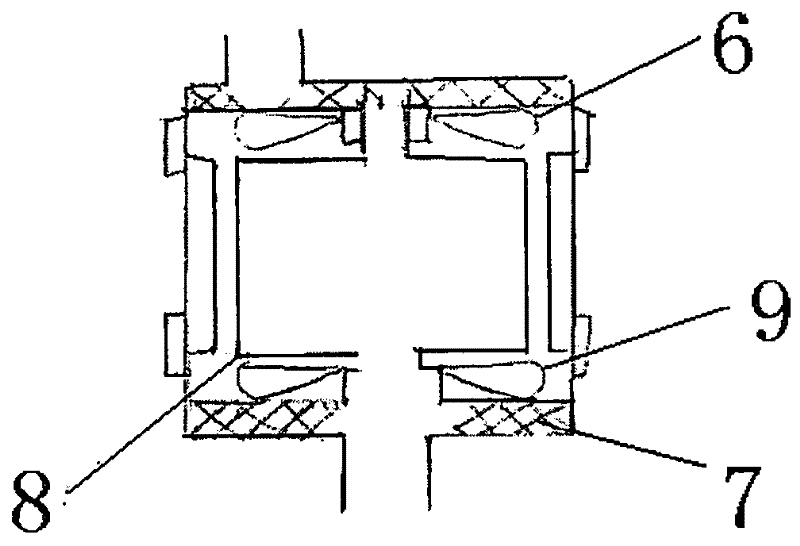

[0010] specific implementation plan

[0011] During actual use, according to the arrangement of the engine, the supercharger dust collector 4 is arranged on the side of the intake pipe 1, so that the air volume of the supercharger 4 is included in the air flow meter for measurement. The power supply of the dust collector is controlled ON-OFF by the ignition switch, and the body of the pressurized dust collector 4 is designed to be connected up and down, which is convenient for cleaning and maintenance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com