Sensing fiber, sensing fiber ring and through-type all-fiber current sensor

A technology of sensing fiber ring and sensing fiber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

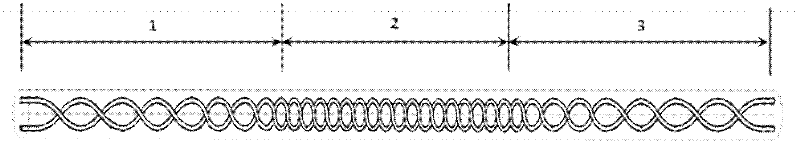

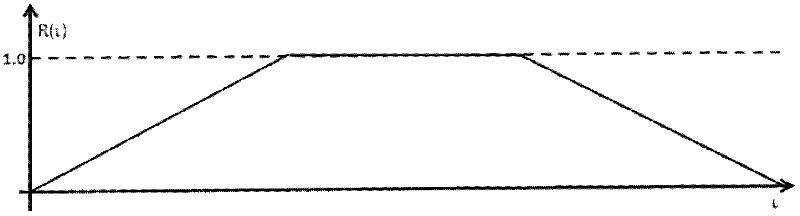

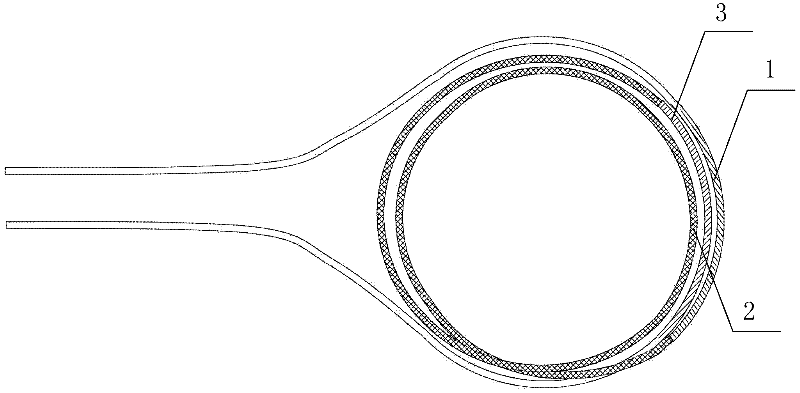

[0022] The sensing optical fiber of the present invention is a depolarized linear birefringence polarization-maintaining optical fiber. The characteristic of this sensing optical fiber is that it includes a helical velocity rising section 1, a helical velocity constant velocity section 2 and a helical velocity decreasing section 3 in turn, as figure 1 As shown, the spiral velocity rising section and the spiral velocity descending section are symmetrical structures, the lengths of both are equal, and the spiral velocity is symmetrically the same. The whole sensing optical fiber can be specifically described as starting from the helical rate of zero, and slowly increasing to the predetermined highest helical rate after the length L1 (this section is the helical rate rising section), and then maintaining the predetermined highest helical rate (this section It is the constant speed section of the spiral rate), and its length is L2, and then after passing through the length of L3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com