X-ray machine imaging device based on automatic diaphragm control

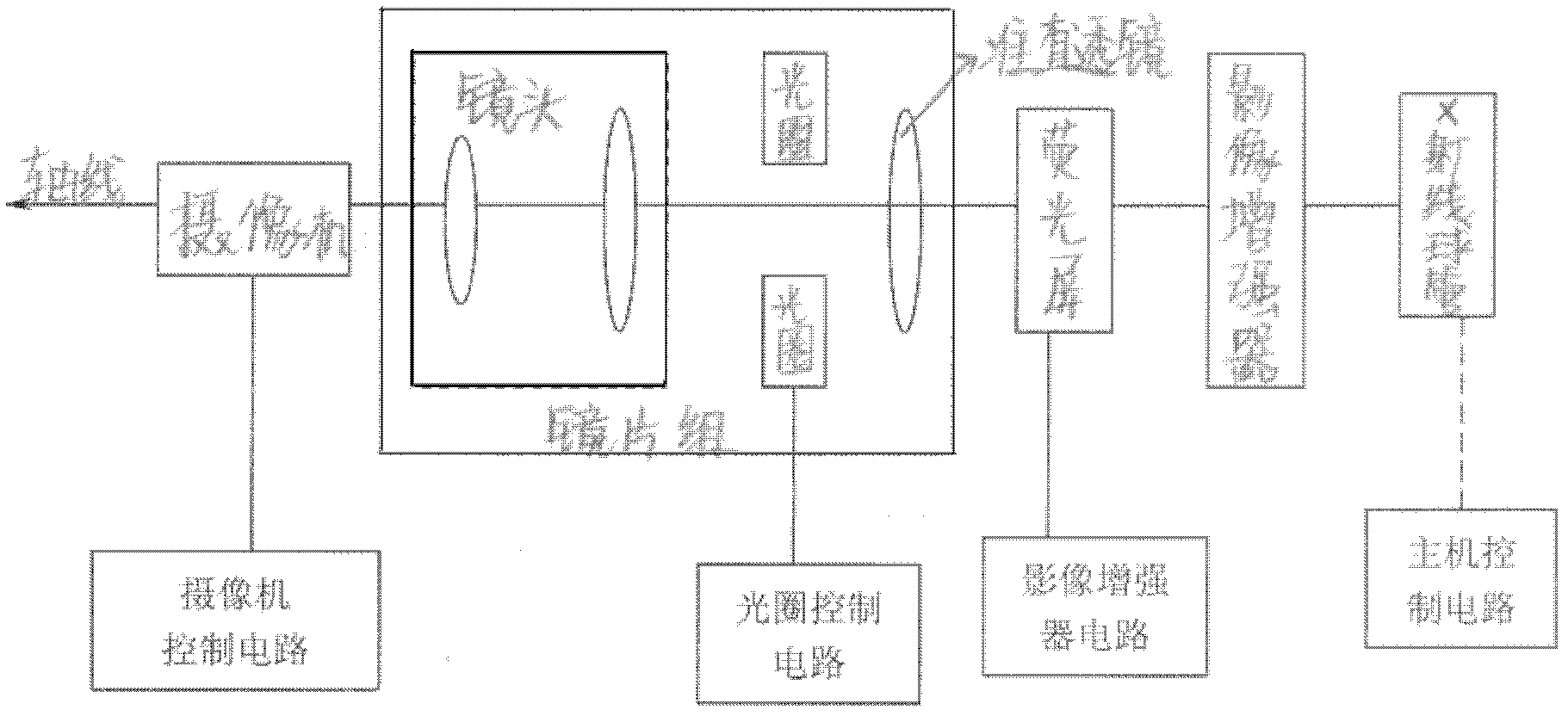

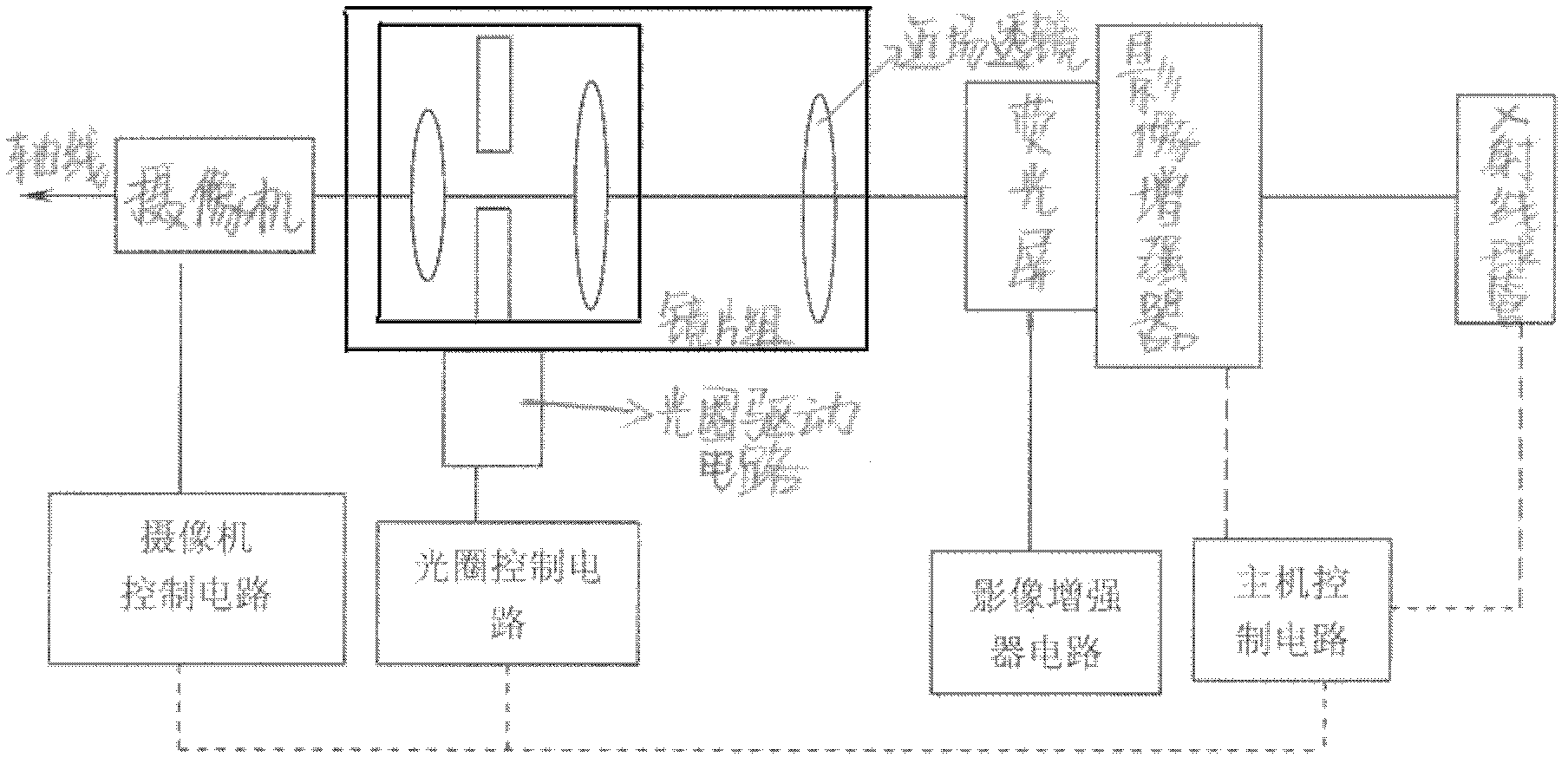

A technology for an X-ray machine and an imaging device, applied in the field of imaging devices, can solve the problems of high requirements for technicians, deteriorating imaging quality, and heavy debugging workload, and achieve the effects of accurate driving position, fast driving speed and good linearity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

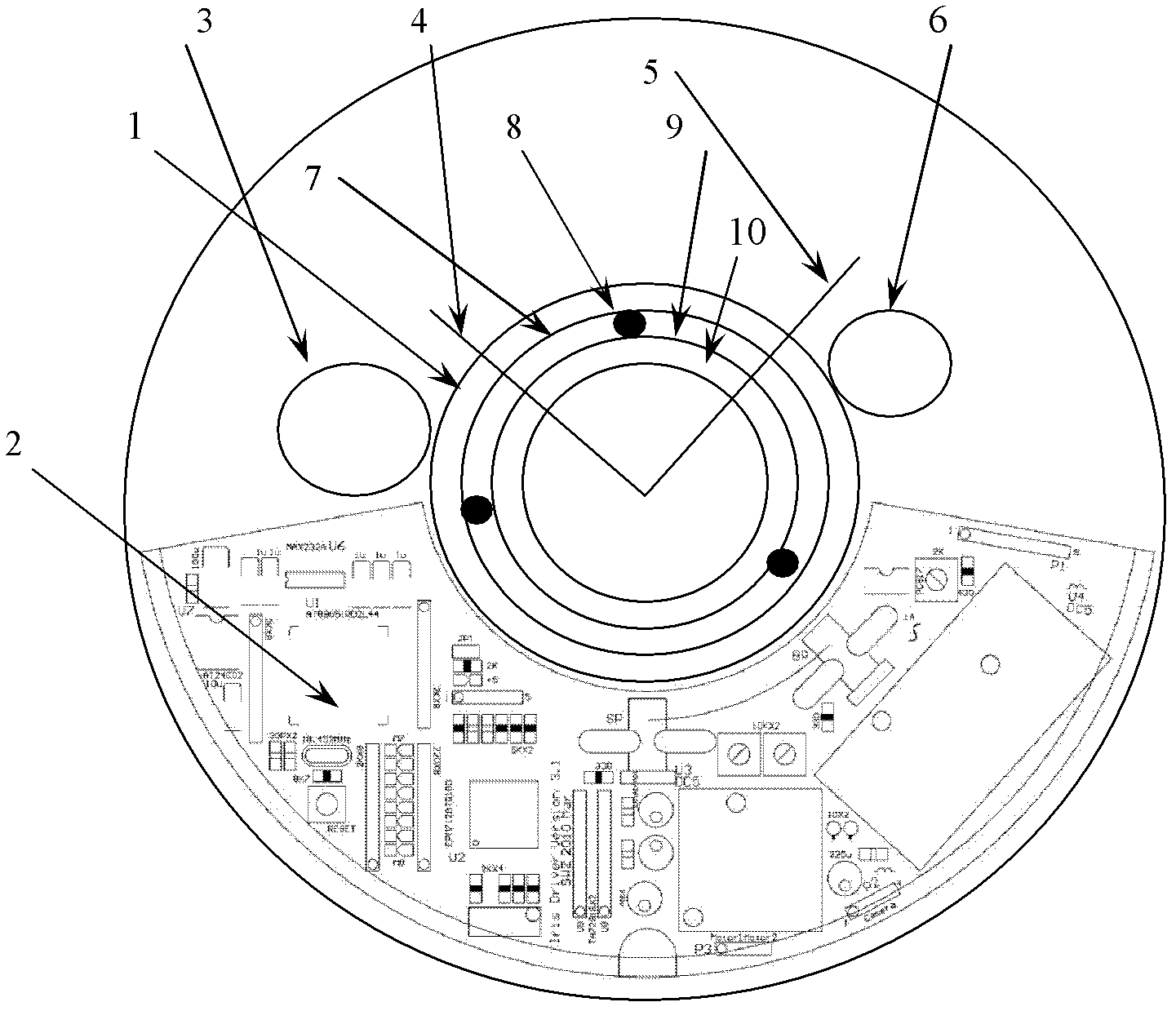

[0032] like image 3 as shown, image 3 It is a side view of an X-ray machine imaging device based on automatic aperture control proposed by the present invention. from image 3 It can be seen that the device includes an aperture positioning ruler 1, a driving circuit 2, a dimming film driving motor 3, a first aperture limit point 4, a second aperture limit point 5, an aperture drive motor 6, a rolling bearing 7, and a flexible coupling 8, Aperture drive ring 9, high resolution manual lens 10 and circumference counter 11.

[0033] Keeping the aperture drive system coaxial with the high-resolution manual lens 10 during assembly is the key to ensure the smooth operation of the system. The assembly error of the current system cannot meet the long-term work and use of the lens. Therefore, between the aperture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com