High bandwidth high speed analog-to-digital converter batch production testing device based on crystal oscillator and method thereof

A technology of analog-to-digital converters and testing devices, applied in the direction of analog/digital conversion calibration/testing, etc., can solve the problems of insufficient ATE performance, inability to test high-bandwidth and high-speed ADC performance at full speed, etc., achieve stable reliability, improve efficiency, and reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

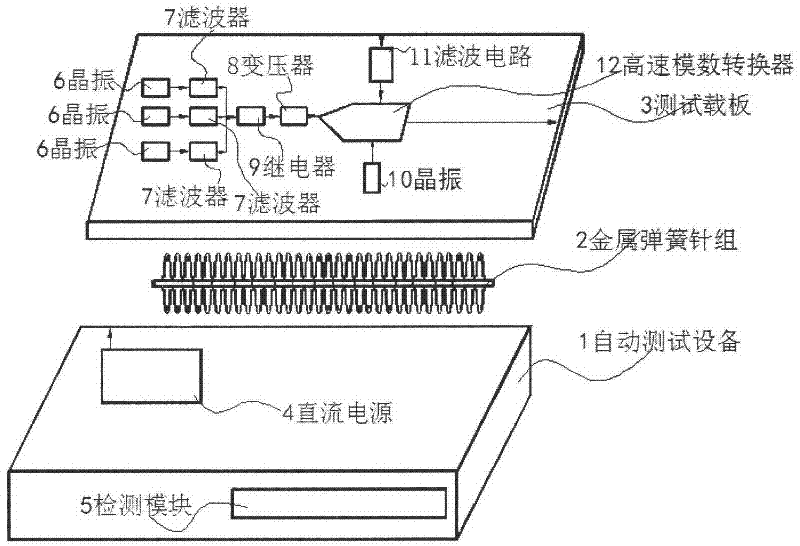

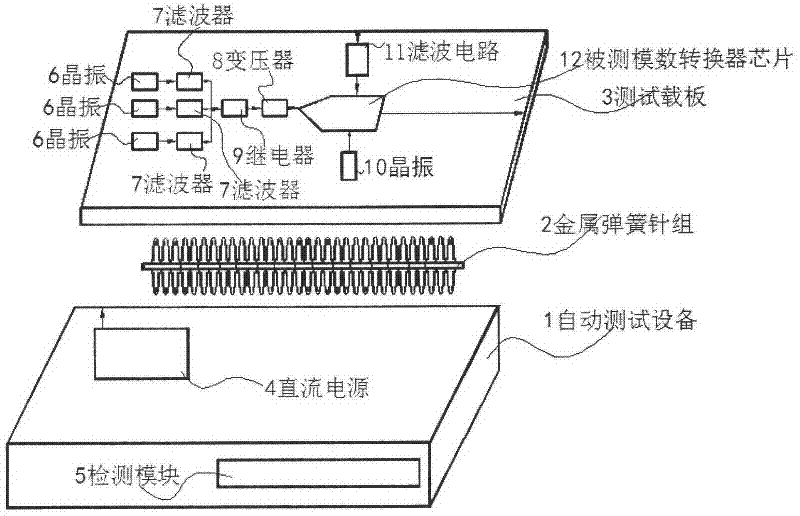

[0035] figure 1 It shows the schematic diagram of the crystal oscillator-based high-bandwidth high-speed analog-to-digital converter mass production test device of the present invention.

[0036] The high-bandwidth high-speed analog-to-digital converter mass production test device based on crystal oscillator includes: automatic test equipment 1, metal pogo pin set 2 and test carrier board 3;

[0037] Metal pogo pin group 2, one end is connected to the automatic test equipment 1, and the other end is connected to the test carrier board 3, and the test carrier board 3 transmits the power supply provided by the automatic test device 1, the test signal, the state command of the analog-to-digital converter chip under test and the receiving test The feedback signal sent by the carrier b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com