Water supply device of after-rolling cooling system

A technology of water supply device and cooling system, applied in metal rolling, metal rolling, metal processing equipment and other directions, can solve the problems of difficult adjustment, high energy consumption, large vibration of terminal equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

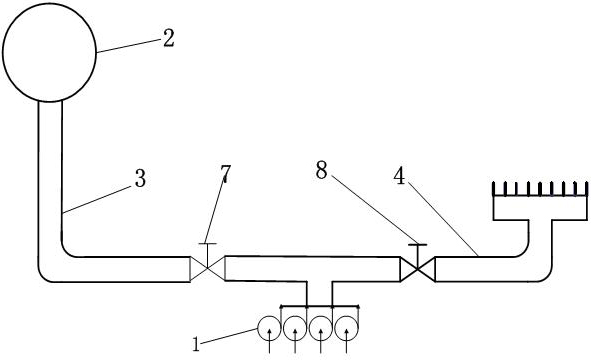

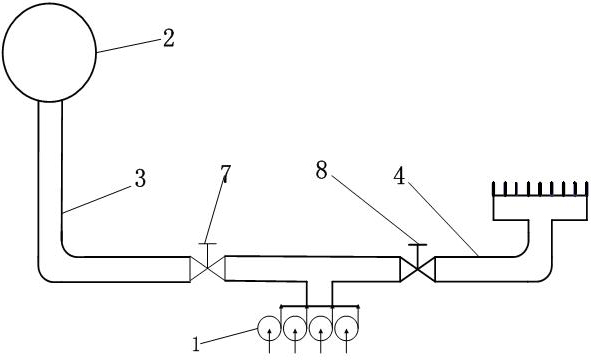

[0011] See figure 1 In the water supply device of the present invention, the water pump 1, the water supply pipeline and the high-level water tower 2, multiple water pumps can be used, and the high-level water tower 2 can use a spherical water tower. The water supply pipeline includes a pipeline 3 connecting the outlet of the water pump 1 to the high-level water tower 2, and a pipeline 4 connecting the outlet of the water pump to the cooling system. A valve 7 is installed on the pipeline 3, and a valve 8 is installed on the pipeline 4.

[0012] During normal operation, both valve 7 and valve 8 in the pipeline are open. When the flow of the water supply pump is greater than the actual water consumption of ultra-fast cooling, the excess water flows back to the high-level water tower through valve 7 and overflows from the overflow of the high-level water tower; When the flow of the water supply pump is less than the actual water consumption of the ultra-fast cooling, the water leve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com