Three-air-valve engine for small-displacement motorcycle

A motorcycle, small displacement technology, applied in engine components, combustion engines, machines/engines, etc., can solve problems such as greater power that affects engine output, small intake tumble flow, and large airflow resistance, and achieves increased intake. Tuyere pressure and flow, increase the speed of airflow turbulence, and eliminate the effect of vortex air choke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with drawings and embodiments.

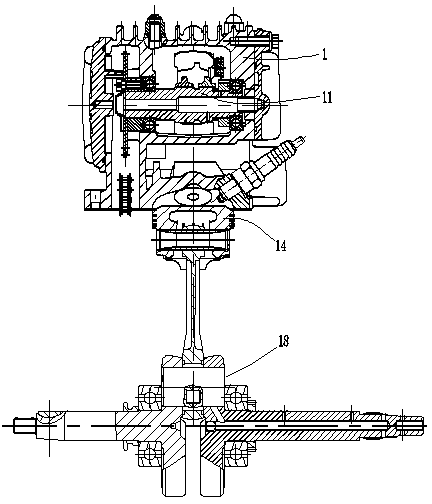

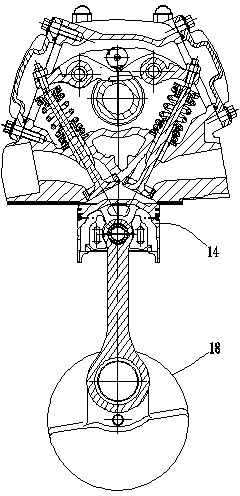

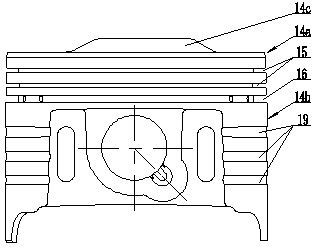

[0049] Such as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 As shown, the cylinder head 1 is fixed on the cylinder block (not shown in the figure), the cylinder block is arranged on the crankcase, and the crank connecting rod mechanism 18 is supported by the bearing in the crankcase, and the crank connecting rod mechanism 18 The small end of connecting rod is connected with piston 14 by piston pin. The piston 14 is composed of two major parts, the piston head 14a and the piston skirt 14b. Wherein, the top surface of the piston head 14a is a plane, and the top surface of the piston head 14a is provided with the first, second, and third three dimples 17, and the first dimple 17 and the second dimple 17 are located at On the same side, the third pit 17 is located on the other side, and the three pits 17 are distributed in an isosceles triangle. The pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com