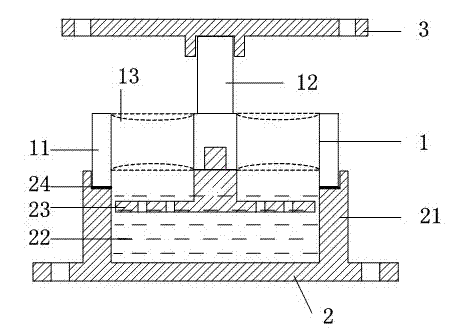

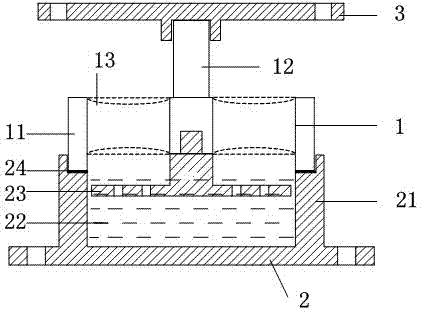

Large-dampness vertical viscoelastic vibration isolating and reducing device

A viscoelastic and vertical technology, applied in the field of broadband excitation work platform, can solve the problem of no vibration damping ability, and achieve the effect of simple and convenient production, reduced shear stiffness and good vibration isolation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] A large damping vertical viscoelastic vibration isolation device of the present invention is composed of a viscoelastic damper 1 and a viscous fluid damper 2, the upper part is a high damping low modulus viscoelastic damper 1, and the lower part is a viscous fluid damper 1 The middle of the fluid damper 2 is an air bladder (equivalent to an air spring) surrounded by a viscoelastic material and a viscous fluid. The upper viscoelastic damper 1 is connected with the upper connecting plate 3 through the guide rod 12, and is connected with the outer cylinder 21 and the piston disc 23 of the lower viscous fluid damper respectively through its outer cylinder 11 and guide rod 12, so that the device The various parts are connected into a whole. The high-damping low-modulus viscoelastic damper 1 is composed of an outer cylinder 11, a guide rod 12 and a viscoelastic material 13; They are respectively connected with the outer cylinder, the connecting plate 21 and the piston disc 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com