Solid-state imaging element, solid-state imaging device, solid-state imaging apparatus, and method for producing polarizing element

A solid-state photography element and solid-state photography technology, applied in the direction of polarizing elements, electric solid devices, electrical components, etc., can solve problems such as difficulties and inorganic particles, and achieve the effects of suppressing fading, excellent extinction characteristics, and suppressing mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

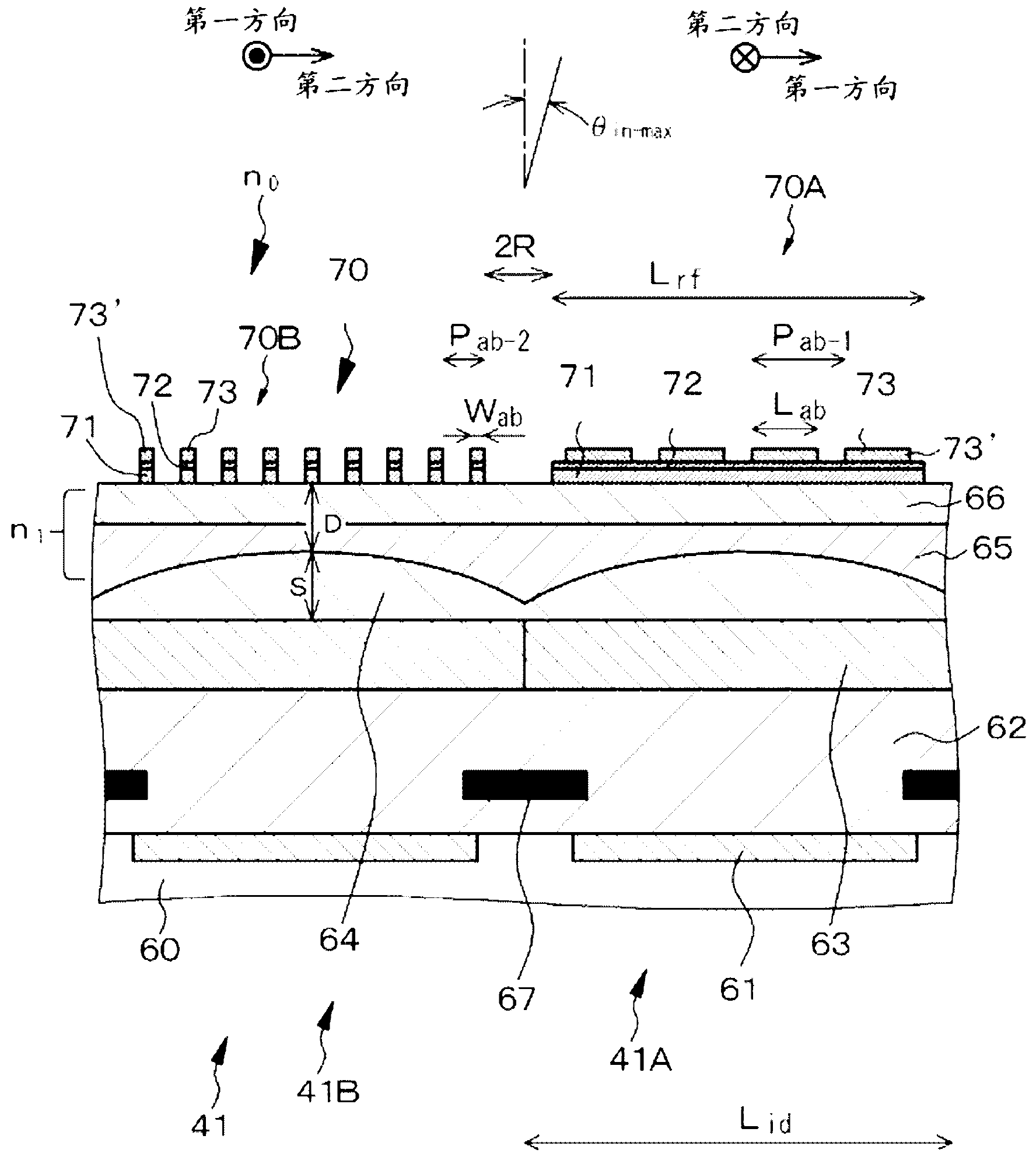

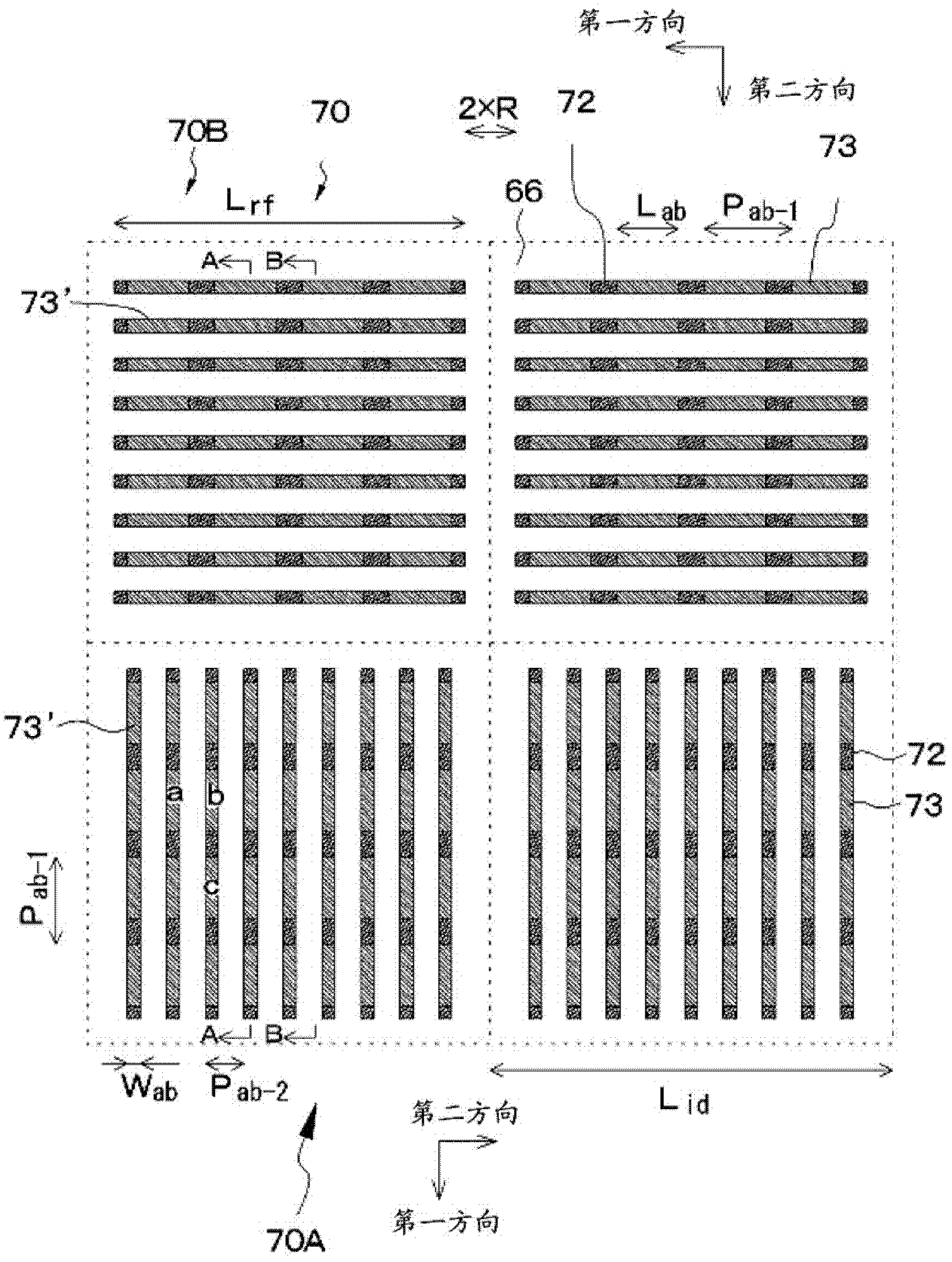

[0070] 2. Embodiment 1 (solid-state imaging element of the present invention, solid-state imaging device of the present invention, imaging equipment, and method of manufacturing a polarizing element)

[0071] 3. Embodiment 2 (variation of the manufacturing method of the polarizing element of Embodiment 1)

[0072] 4. Embodiment 3 (variation of the manufacturing method of the polarizing element of Embodiment 2)

[0073] 5. Embodiment 4 (variation of Embodiment 1)

Embodiment 5

[0074] 6. Embodiment 5 (Modification of the solid-state imaging device of the present invention)

[0075] 7. Embodiment 6 (Modification of the solid-state imaging device of Embodiment 5)

[0076] 8. Embodiment 7 (another modification of the solid-state imaging device of Embodiment 5)

[0077] 9. Embodiment 8 (further modification of the solid-state imaging device of Embodiment 5)

[0078] 10. Embodiment 9 (further modification of the solid-state imaging device of Embodiment 5)

[0079] 11. Embodiment 10 (further modification of the solid-state imaging device of Embodiment 5)

[0080] 12. Embodiment 11 (further modification of the solid-state imaging device of Embodiment 5)

[0081] 13. Embodiment 12 (variation of Embodiment 11), others

[0082] [Description of the solid-state imaging element of the present invention, the solid-state imaging device, imaging equipment, and polarizing element of the present invention, and the overall description]

[0083]In the polarizing el...

Embodiment 2

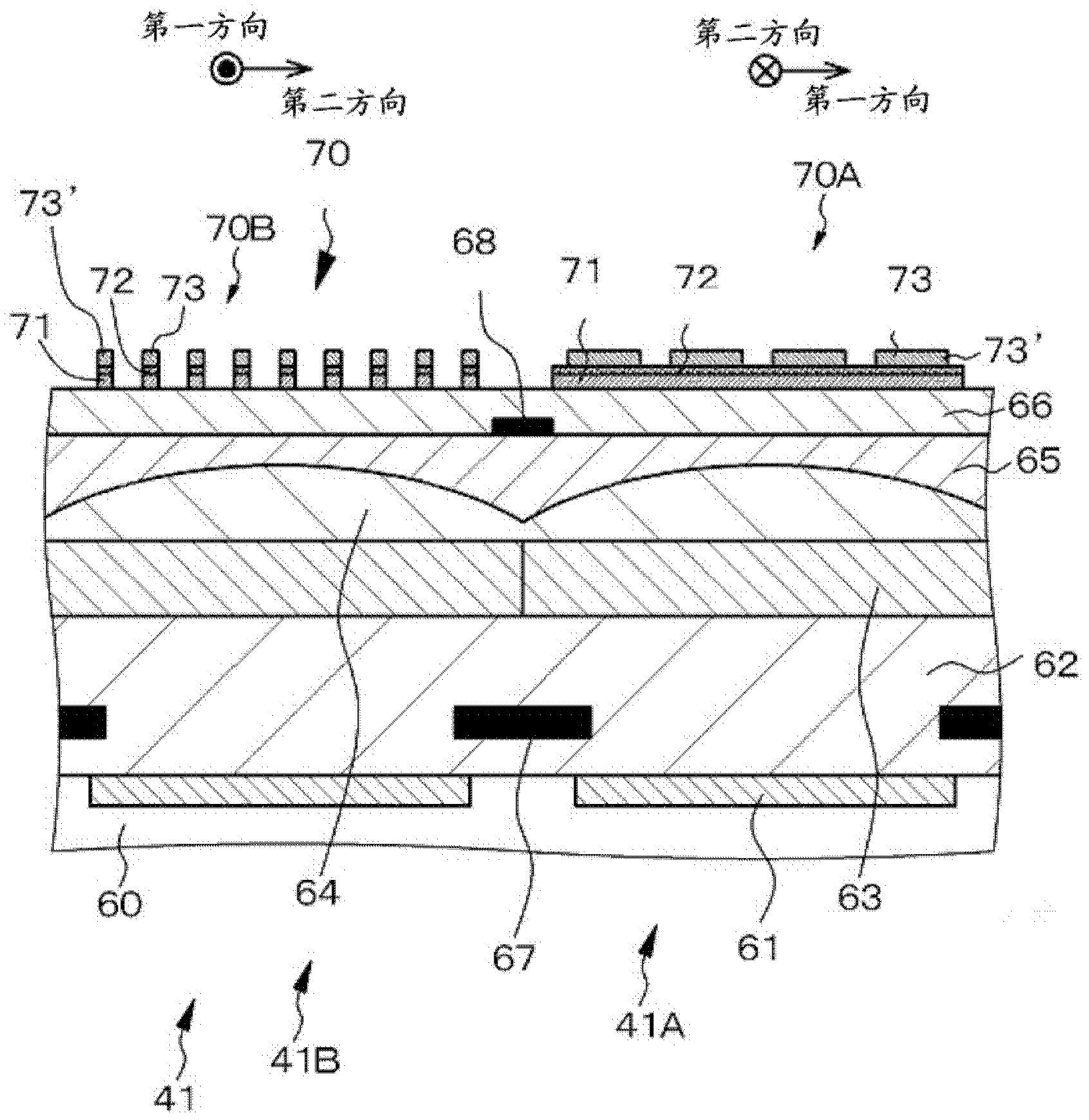

[0227] Embodiment 2 is a modification of Embodiment 1. However, compared with the CVD method, the ADL method can perform film formation on the side surface of the polarizing element 70 more similarly. Therefore, it is possible to prevent reduction in the optical characteristics of the polarizing element. Especially due to AlO x and HfO x A protective film made of such a metal oxide has a high ability to protect a polarizing element, is thin, and can be formed similarly. Therefore, it can function as a high-quality protective film without causing a decrease in optical characteristics.

[0228] In Embodiment 2, the formation pitch P along the second direction is formed ab-2 =180nm, width W ab =80nm, polarizing element 70 and space between polarizing element 70 (P ab-2 -W ab )=100nm polarizing element 70. Specifically, in Example 2, in the same process as [Process-130] of Example 1, after removing the etching mask layer 92, the AlO x or HfO x The formed protective film 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com