Alternating-current non-contact voltage regulator

An alternating current, non-contact technology, applied in the field of electronic technology, can solve the problems of rough voltage classification, narrow voltage stabilization range, slow switching response speed, etc., and achieve fast response time, no waveform distortion, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

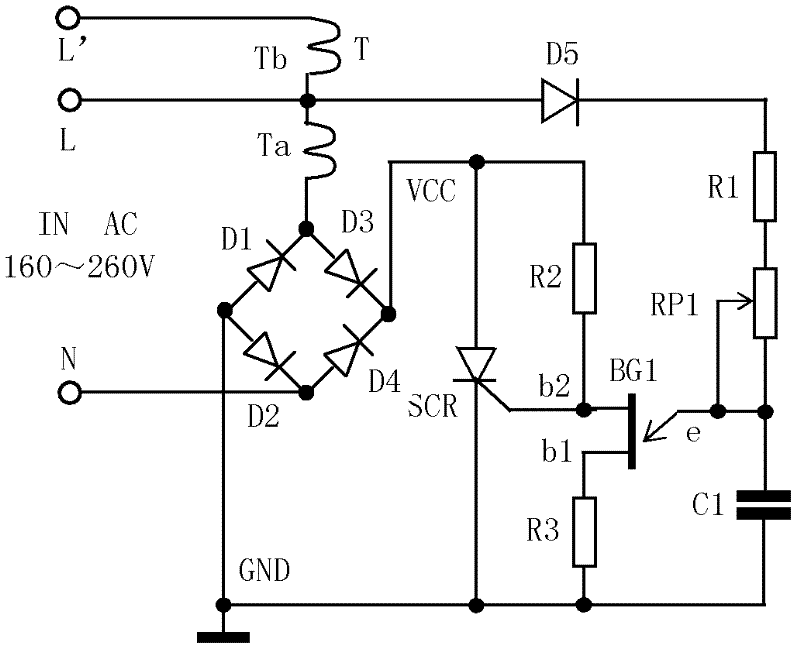

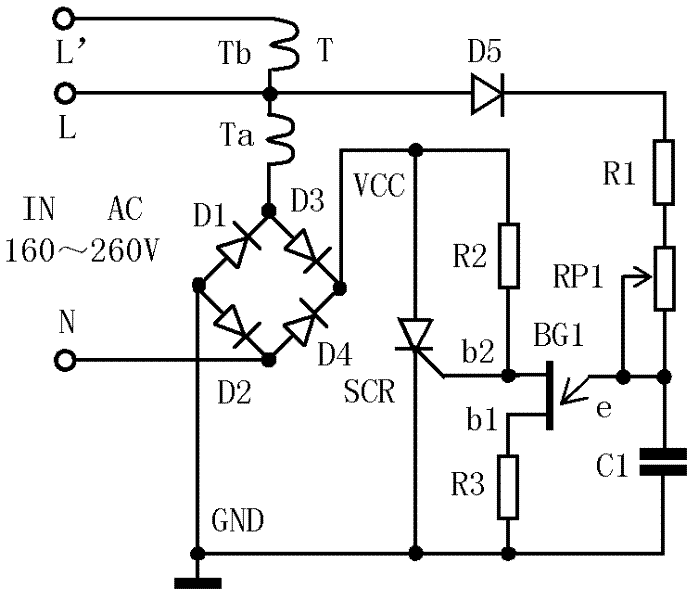

[0013] According to attached figure 1 The present invention can be realized by implementing the circuit working principle diagram and description of the accompanying drawings of the AC non-contact voltage stabilizer and the technical requirements of the components and parts described below.

[0014] Component technical parameters and selection

[0015] T is a self-coupling voltage regulator, and the power of the self-coupling voltage regulator T is required to be greater than 1 / 3 of the power of the voltage regulator;

[0016] D1~D5 are silicon rectifier diodes, the model is IN5408, or use silicon rectifier diodes with a rectification current of more than 3A and a withstand voltage greater than 600V;

[0017] SCR is a one-way thyristor, which requires a current greater than 5A and a withstand voltage of more than 600V, or a one-way thyristor with a large margin in technical parameters; BG1 is a single-junction transistor, and the model is BT33;

[0018] Use 3W metal film res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com