Transitional connection method for heating rod and water cooling electrode of crystal growing furnace

A water-cooled electrode, transition connection technology, applied in the shape of heating elements, ohmic resistance heating parts and other directions, can solve the problems of arcing electrodes, thermal damage, inconvenient installation and maintenance, etc., to achieve convenient installation and maintenance, avoid electrode thermal damage, avoid bad contact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

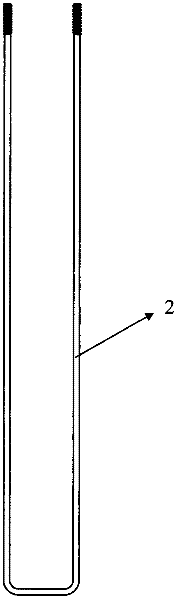

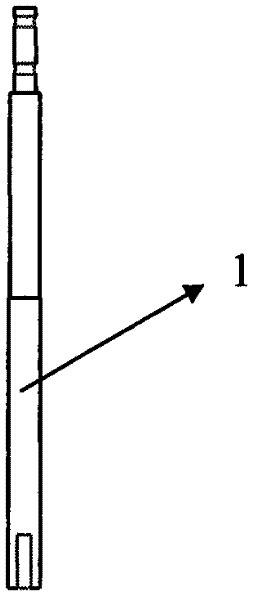

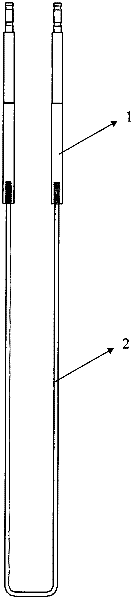

[0014] exist figure 1 , 2 In 3, a transitional connection method between a heating rod and a water-cooled electrode for a crystal furnace, the two ends of the heating rod (2) are processed into an external thread shape; and then one end of the metal rod (1) is set to match the electrode installation position Install the plane, and drill a threaded hole at the position of the installation plane, and the other end is processed into an internal threaded hole matching the external thread of the heating rod (2), and the cross-sectional area of the metal rod (1) is at least that of the heating rod (2). 1.8 times the cross-sectional area. When installing and implementing, first connect the two ends of the heating rod (2) to the corresponding ends of the two metal rods (1), and then fix the other ends of the two metal rods (1) to the water-cooled heater through the threaded holes with refractory screws. At the electrode installation position, a transitional connection between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com