Electrical discharge grinding machining method of overlapped-type double-layer inner-outside honeycomb ring

A grinding and overlapping technology, which is applied in electric processing equipment, metal processing equipment, electrode manufacturing, etc., can solve the problems of unfavorable and stable electrical discharge machining, etc., and achieve uniform material removal, high honeycomb surface quality, and radial runout small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

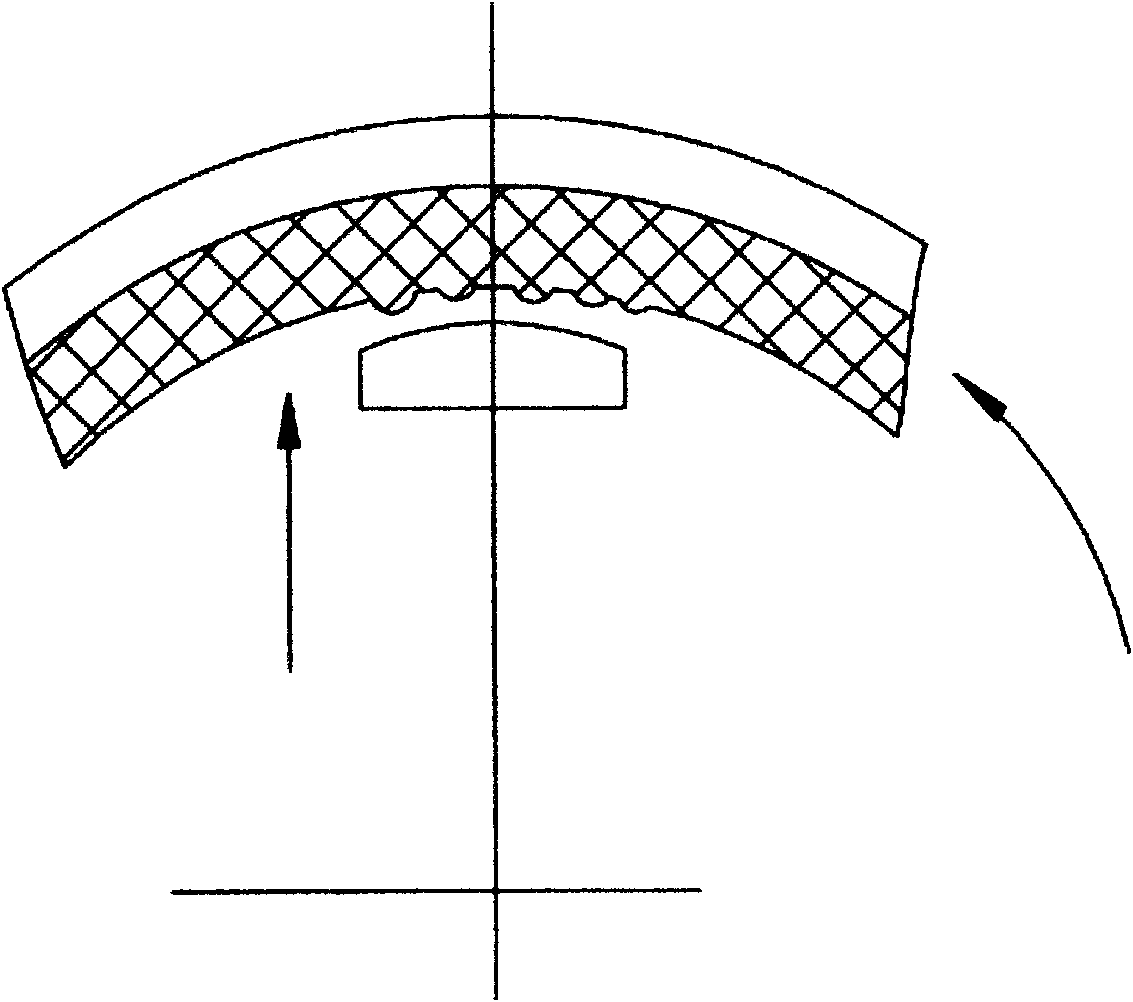

[0019] This embodiment provides an overlapping double-layer inner and outer honeycomb ring EDM processing method, which is characterized in that: the overlapping double-layer inner and outer honeycomb ring EDM processing method uses a fixed electrode diameter In the limit servo mode, the electrode is made into an arc segment close to the diameter of the workpiece, and installed on the spindle head of the machine tool. The electrode is fixed during processing, and the turntable of the machine tool and the workpiece make continuous rotary motion around the electrode, and the electrode moves in the radial direction. Servo machining until the erosion amount reaches the set value, the discharge between the electrode and the workpiece stops, and the entire machining process ends;

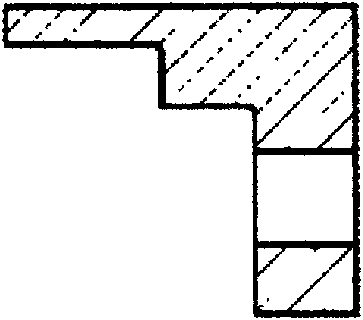

[0020] The electrodes used are special electrodes, and the overall structure of the special electrodes is a fan-shaped structure in the horizontal direction and a ladder structure in the vertical direction...

Embodiment 2

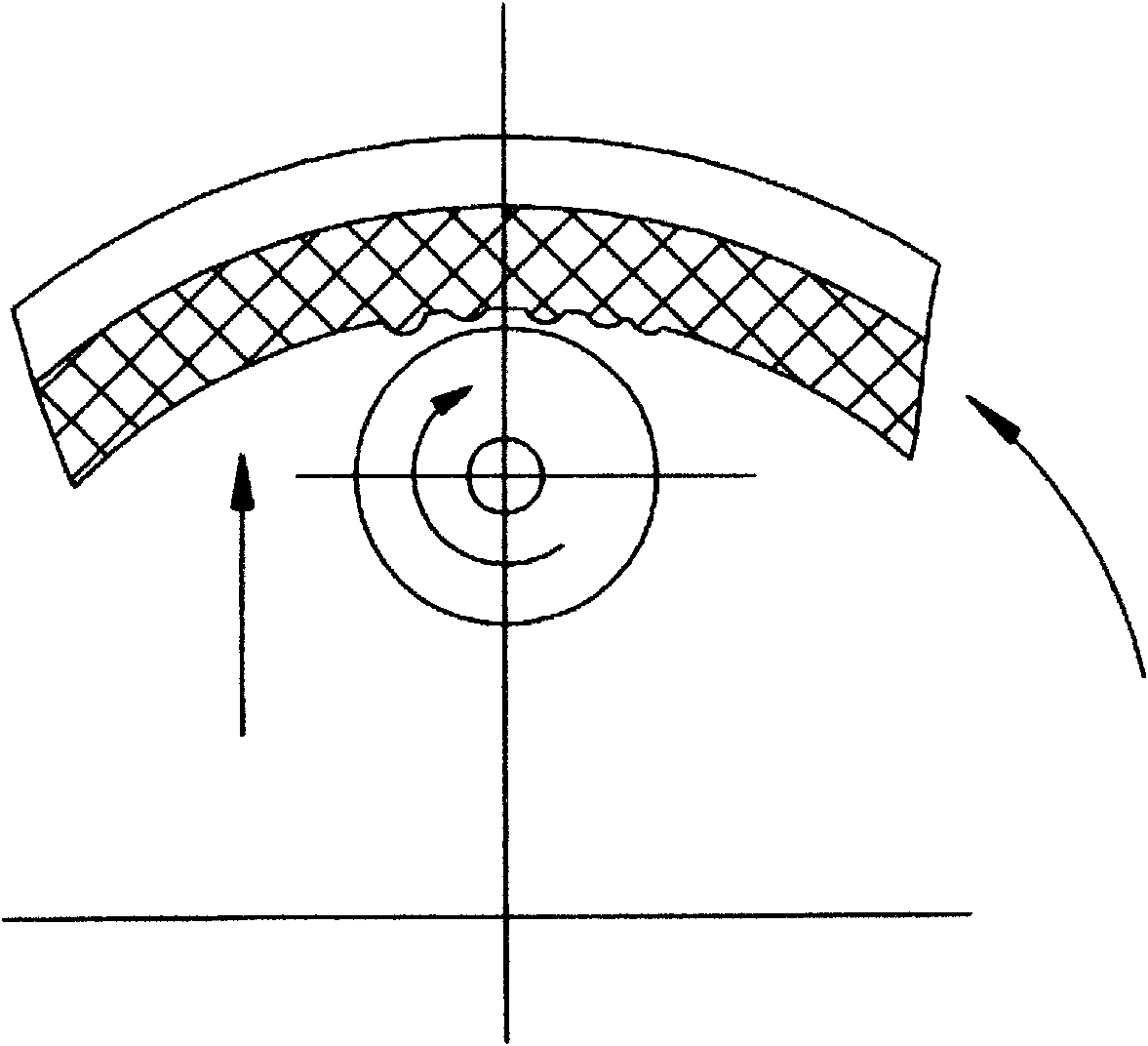

[0025] This embodiment provides an overlapping double-layer inner and outer honeycomb ring EDM processing method, which is characterized in that: the overlapping double-layer inner and outer honeycomb ring EDM processing method uses a fixed electrode diameter In the limit servo mode, the electrode is made into an arc segment close to the diameter of the workpiece, and installed on the spindle head of the machine tool. The electrode is fixed during processing, and the turntable of the machine tool and the workpiece make continuous rotary motion around the electrode, and the electrode moves in the radial direction. Servo machining until the erosion amount reaches the set value, the discharge between the electrode and the workpiece stops, and the entire machining process ends;

[0026] The electrodes used are special electrodes, and the overall structure of the special electrodes is a fan-shaped structure in the horizontal direction and a ladder structure in the vertical direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com