Cylinder manufacturing system

A technology for manufacturing systems and cylinders, applied to labels, external support, transportation and packaging, etc., can solve problems such as low production efficiency, high technical difficulty in labeling the outer surface of packaging containers, and large cost investment, so as to improve production efficiency and save Human production costs, the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

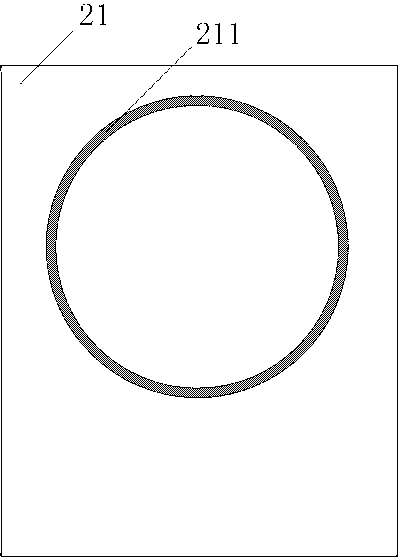

[0021] The embodiment of the present invention is used to glue and cut the sheets into a plurality of cylindrical food outer packages, including a labeling device and a welting device.

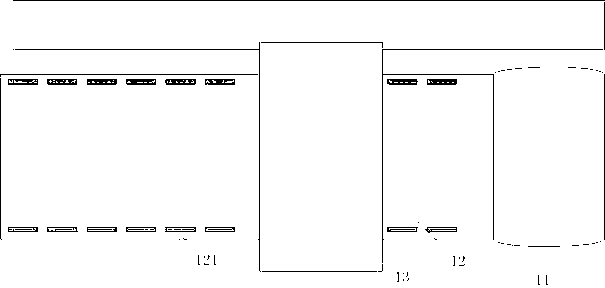

[0022] Such as figure 1 Shown is a labeling device according to an embodiment of the present invention, including a sheet feeding rubber wheel 11 , a limit track 12 and a labeling head 13 .

[0023] The sheet-feeding rubber wheels 11 are used to transport the rolled sheets to the labeling device and the welting device for processing.

[0024] The sheet is labeled by the labeling head 13 through the limiting track 12 , and the limiting track is used to transport the sheet.

[0025] The labeling head 13 is implemented by a labeling device in the prior art.

[0026] Limiting piec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com