Method for manually replacing bucket type elevator belt

A bucket elevator, manual replacement technology, applied in conveyors, transportation and packaging, etc., can solve the problems of low safety factor, time-consuming 60 minutes, long consumption time, etc., achieving short replacement time, avoiding processes, and high safety factor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

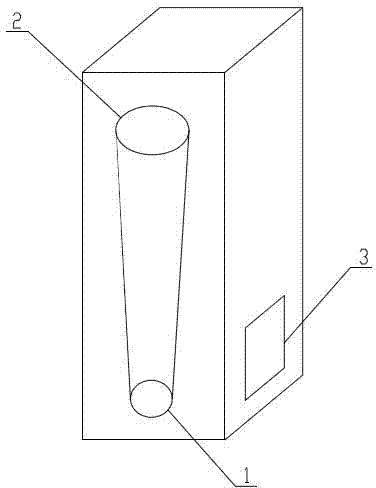

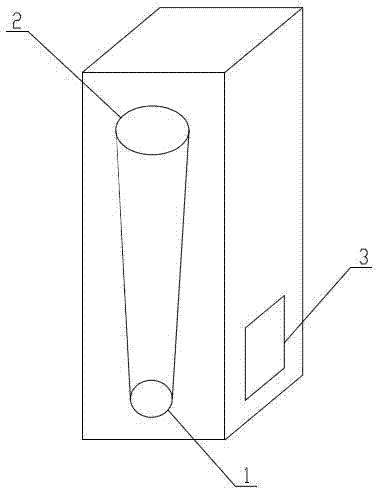

[0011] like figure 1 As shown, the manual replacement method of the bucket elevator belt of the present invention comprises the following steps:

[0012] 1. First prepare the tools, materials and staff required for the replacement work;

[0013] 2. Notify the relevant staff to stop the machine at high material level, and then cut off the work of the motor;

[0014] 3. Open the tail observation ports on both sides of the bucket elevator, and arrange two staff members at the first wheel of the bucket elevator;

[0015] 4. Cut off the old belt with a belt knife through one of the tail viewing ports, and then notify the staff at the first wheel to crank to the appropriate position in sequence;

[0016] 5. Connect the prepared new belt with a broken end of the old belt through the above-mentioned tail observation port with a belt special link buckle;

[0017] 6. Notify the staff at the first round to turn the car until the old belt is completely output from the other rear viewin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com